Press release

Tungsten Carbide Market to Reach USD 38.4 Billion by 2035, Driven by Metalworking and Aerospace Investments, Reports Fact.MR

The global tungsten carbide market is projected to reach USD 38.4 billion by 2035, rising from USD 22.8 billion in 2025, according to the latest report by Fact.MR. The market is anticipated to expand at a compound annual growth rate (CAGR) of 5.3%, underpinned by accelerating industrial automation, increased demand from metal cutting and mining sectors, and surging applications in the aerospace and defense industries.The Fact.MR study, "Tungsten Carbide Market Size, Share, and Forecast 2025-2035," highlights the metal's critical role in precision machining and heavy-duty cutting tools, enabling global manufacturers to meet efficiency and durability targets amid rising material performance demands.

Industrial Metal of the Future: Where Durability Meets Precision

"Tungsten carbide remains indispensable for next-generation industrial productivity," said a Fact.MR senior analyst. "Its superior hardness, temperature resistance, and recyclability make it the backbone of the precision tooling and mining sectors. As aerospace and EV manufacturing expand, investors are recognizing tungsten carbide's pivotal role in the future of advanced material science."

Between 2025 and 2030, the market is projected to grow by USD 7.1 billion, supported by modernization in automotive and aerospace machining. From 2030 to 2035, an additional USD 8.5 billion in growth is expected, fueled by material recycling technologies and high-performance coating applications.

To access the complete data tables and in-depth insights, request a Discount report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=8467

Market Overview at a Glance

Metric Global Estimate

Market Value (2025) USD 22.8 billion

Forecast Value (2035) USD 38.4 billion

CAGR (2025-2035) 5.3%

Top Application Metal Cutting Tools

Dominant End-Use Industry Automotive & Aerospace

Fastest-Growing Region Asia Pacific

Asia Pacific Leads Global Production and Consumption

Asia Pacific dominates global tungsten carbide production, accounting for over 45% of total revenues in 2025. The region's leadership stems from strong industrial output in China, Japan, and South Korea, where tungsten carbide tools are vital to automotive and electronics manufacturing.

Europe remains a key hub for precision tooling and high-performance coating technologies, with Germany and Italy leading adoption across aerospace and industrial automation applications. North America follows closely, driven by investments in defense manufacturing and advanced machining technologies for EV production lines.

Five Key Investment Drivers

Expansion in Metal Cutting and Machining Tools: Increasing demand for high-efficiency tools in automotive, aerospace, and general manufacturing sectors.

Aerospace and Defense Growth: Rising investments in precision machining for aircraft components and defense-grade materials.

Sustainability and Recycling: Surge in reclaimed tungsten carbide use to reduce production costs and emissions.

Advanced Coating Technologies: Adoption of tungsten carbide coatings for wear resistance and longer component life cycles.

Industrial Automation: Robotic manufacturing and CNC systems drive steady demand for durable and precise cutting tools.

Competitive Landscape

Prominent players in the tungsten carbide market include:

Sandvik AB

Kennametal Inc.

CERATIZIT S.A.

Sumitomo Electric Industries Ltd.

Mitsubishi Materials Corporation

IMC Group (Iscar)

GuangDong XiangLu Tungsten Co., Ltd.

Together, these companies hold over 55% of the global market, with strategies focusing on supply chain optimization, recycling partnerships, and innovations in composite carbide blends to improve strength-to-weight ratios.

Market Outlook: Precision Materials for the Digital Manufacturing Era

By 2035, tungsten carbide's importance will extend beyond cutting tools. The material is expected to play a critical role in additive manufacturing, EV drivetrain components, and industrial wear parts. With global manufacturing shifting toward high-precision, sustainable systems, tungsten carbide's recyclability and durability position it as an essential asset for future-ready industries.

"The tungsten carbide ecosystem is evolving into a circular industrial model," added the Fact.MR analyst. "Investors should view this market as a cornerstone of advanced manufacturing - combining resilience, innovation, and long-term value creation."

View Related Reports -

Tungsten Carbide Powder Market https://www.factmr.com/report/tungsten-carbide-powder-market

Silicon Carbide (Carborundum) Market https://www.factmr.com/report/4581/silicon-carbide-market

Silicon Carbide Composites Market https://www.factmr.com/report/silicon-carbide-composites-market

Niobium Carbide Market https://www.factmr.com/report/niobium-carbide-market

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here:

https://www.factmr.com/checkout/8467

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - Contact Sales: sales@factmr.com

- Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a leading market research and consulting agency serving 80% of Fortune 1000 clients. With global offices in the U.S., U.K., and India, Fact.MR delivers actionable insights across 1,500+ markets, helping investors and business leaders make data-backed strategic decisions in fast-evolving industrial ecosystems.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Tungsten Carbide Market to Reach USD 38.4 Billion by 2035, Driven by Metalworking and Aerospace Investments, Reports Fact.MR here

News-ID: 4253427 • Views: …

More Releases from Fact.MR

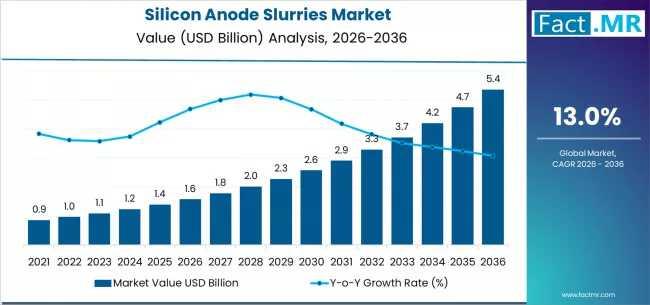

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

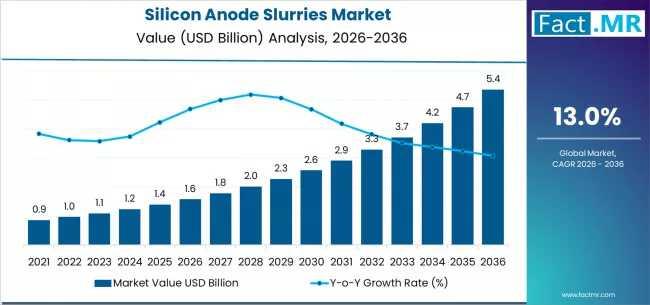

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

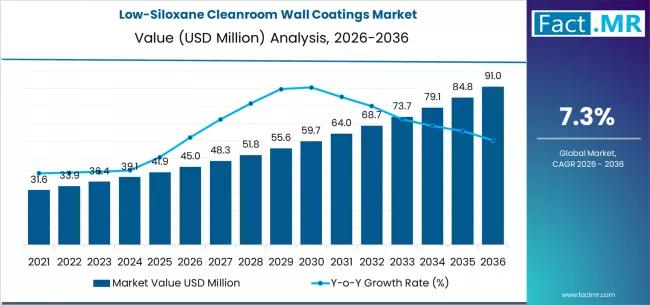

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

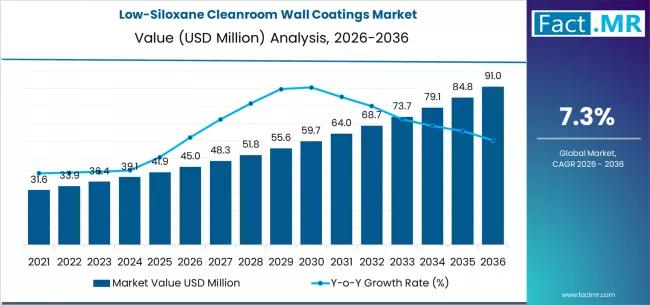

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

More Releases for Carbide

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…