Press release

The Future Leading PP Coaming Box Supplier for Tomorrow's Sustainable and Customized Solutions

I. Introduction: Engineering Resilience in Modern LogisticsThe global imperative for supply chain efficiency and sustainability is driving a technological evolution in logistics packaging. Companies are urgently seeking solutions that minimize environmental impact while maximizing product protection and reducing operational costs. At the vanguard of this engineering shift is Jiangyin Lonovae Technology Co., Ltd., a specialized plastic manufacturer committed to redefining Returnable Transport Packaging (RTP).

Established in 2015 in the manufacturing hub of Jiangyin City, China, Lonovae operates with a team of over 100 staff across a 3,000 square meter facility, intensely focused on durable plastic manufacturing. Central to their innovative offerings is the product that cements their reputation as the Future Leading PP Coaming Box Supplier(https://www.lonovae.com/about-us/)-the Collapsible Pallet Pack Container. This advanced, three-piece system-comprised of a rugged plastic pallet, a lid, and the namesake PP Coaming/Sleeve made from high-strength PP Honeycomb Panel-is engineered for superior structural integrity and ultra-efficient collapse ratio. The PP Coaming Box is particularly valued for its lightweight nature, exceptional impact resistance, and ability to drastically reduce volumetric space during empty returns, providing customers with a sustainable and cost-effective bulk handling solution across diverse industrial applications. Furthermore, Lonovae has recently extended its manufacturing acumen into personal and home care products, focusing on health and cleanliness.

II. Industry Outlook: The Strategic Ascent of Returnable Transport Packaging (RTP)

The landscape of logistics packaging is experiencing exponential change, positioning RTP solutions like those from Lonovae as indispensable tools for 21st-century commerce. This section analyzes the key trends fueling the demand for advanced plastic containers.

A. Mandates for the Circular Economy and Carbon Reduction

The most significant external pressure driving the RTP market is the convergence of global environmental policies and corporate sustainability commitments. Governments are enacting stricter regulations on packaging waste, while large corporations are setting ambitious Net-Zero targets. Single-use packaging is increasingly viewed as a liability. RTP, particularly durable, recyclable plastic solutions, offers a direct path to compliance and sustainability goals. By facilitating multiple uses and reducing reliance on virgin materials, Lonovae's systems provide companies with measurable reductions in waste generation and carbon emissions, making them strategically vital assets rather than disposable costs.

B. Automation and the Demand for Dimensional Precision

The logistics industry is heavily investing in warehouse automation, including robotics, Automated Storage and Retrieval Systems (AS/RS), and Automated Guided Vehicles (AGVs). These automated systems require packaging with extremely high dimensional consistency and stability. Plastic collapsible containers, manufactured with precision molding techniques, meet these exacting standards far better than traditional materials. Lonovae's standardized product lines ensure seamless integration into these automated environments, reducing the risk of operational disruptions and maximizing throughput efficiency.

C. The Customization and Durability Imperative

As supply chains become more complex, the need for customized, protective packaging has intensified. Sectors like electric vehicle (EV) manufacturing and high-tech electronics require specialized dunnage and structurally sound containers to transport sensitive, high-value components. The PP Honeycomb material used in Lonovae's coaming boxes is highly adaptable, allowing for custom inserts and partitions while offering superior resistance to shock, moisture, and chemical exposure, a level of protection unmatched by traditional materials. This specialized demand guarantees sustained market growth for technologically advanced suppliers.

III. Lonovae's Competitive Advantage: Building Tomorrow's Logistics Infrastructure

Lonovae's success is built upon a concentrated focus on engineering excellence, specialization in advanced materials, and a proactive approach to solving complex logistics challenges.

Core Strengths and Value Proposition

Lonovae differentiates itself through a robust business model centered on material mastery and customer-focused design. Their core strengths deliver tangible results:

Mastery of PP Honeycomb Technology: Lonovae's specialization in the PP Honeycomb Panel for the coaming/sleeve component ensures their Pallet Pack Containers offer an industry-leading strength-to-weight ratio. This reduces shipping weight while providing exceptional impact absorption, superior cushioning, and inherent resistance to water and corrosion-critical for high-value and sensitive freight.

Optimized Cube Utilization: The ultra-efficient collapse ratio of their containers is a key financial driver. By folding flat to minimize return volume, Lonovae's systems drastically cut down on back-haul logistics costs and increase warehouse density, offering immediate ROI to clients.

End-to-End Durability and Low TCO: Lonovae manufactures its RTP to endure hundreds of cycles through demanding industrial environments. The long lifespan and low maintenance requirement significantly reduce the Total Cost of Ownership (TCO) compared to less durable, disposable alternatives, proving that sustainability is also fiscally responsible.

Integrated Product Portfolio: Beyond the PP Coaming Box, Lonovae offers a comprehensive range, including Collapsible Bulk Containers, Collapsible Crates, and raw PP Honeycomb Panel. This versatility allows the company to provide complete, integrated packaging solutions for various component sizes and handling requirements, simplifying procurement for their clients.

Adaptability and Diversification: Lonovae's manufacturing expertise extends beyond logistics. Their expansion into high-quality personal and home care products (e.g., disposable cotton towels) showcases their adaptability, leveraging core material knowledge to meet consumer demands for health and comfort, thereby stabilizing and diversifying the company's revenue streams.

IV. Product Applications and Noteworthy Client Successes(https://www.lonovae.com/products/)

Lonovae's RTP solutions are deployed across a broad spectrum of demanding industrial environments, translating their core strengths into tangible operational benefits for clients worldwide.

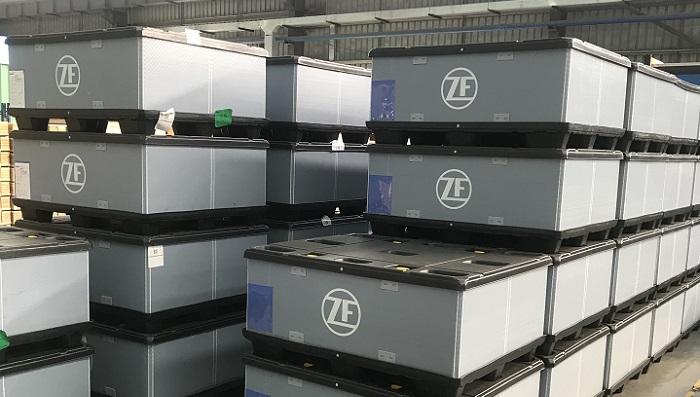

A. Automotive and Tier Supplier Logistics

The automotive industry relies heavily on Lonovae's Plastic Collapsible Pallet Pack Containers (PP Coaming Boxes) for the secure transport of large, expensive components like dashboards, headlights, and transmission parts. In closed-loop systems, Lonovae's boxes ensure zero damage, and the high collapse ratio means that the empty containers consume minimal space on the return route to the supplier, streamlining the entire manufacturing ecosystem.

B. White Goods and Appliance Manufacturing

Manufacturers of washing machines, refrigerators, and air conditioners utilize Lonovae's Collapsible Bulk Containers for internal logistics and external shipping of sub-assemblies and raw materials. The containers' stackability and resistance to wear and tear improve warehouse organization and ensure materials are protected during in-plant handling, accelerating production line feed.

C. Food Processing and Retail Distribution

For the food and beverage industry, the hygiene and easy-to-clean nature of plastic are critical. Lonovae's Collapsible Crates are essential for moving fresh produce, packaged goods, and ingredients. Their open-grid designs (where applicable) allow for ventilation and rapid cooling, while the durable plastic ensures the crates withstand frequent washing and reuse, minimizing cross-contamination risks and complying with food safety standards.

Lonovae has partnered with numerous global corporations in these demanding sectors, successfully implementing RTP programs that have demonstrably reduced packaging procurement by up to 50% and virtually eliminated packaging waste, showcasing their commitment to delivering both economic and environmental value.

V. Conclusion: Your Partner in Logistics Innovation

Jiangyin Lonovae Technology Co., Ltd. is positioned not just as a supplier, but as a strategic partner dedicated to future-proofing global logistics. By focusing on advanced materials and specialized engineering, they are setting new benchmarks for durability, efficiency, and sustainability. As the demand for responsible logistics accelerates, Lonovae's expertise in the PP Coaming Box and other RTP solutions makes them an essential choice for any company seeking to optimize its supply chain and meet tomorrow's environmental challenges.

For a complete overview of Lonovae's sustainable RTP solutions and their innovative product lines, please visit the official website:

https://www.lonovae.com/

17-1509, Moka Intl Building, Dongwaihuan Road, Jiangyin City, Jiangsu Province, China-214432

sophia@lonovae.com

frank@lonovae.com

8618661010305

8618118865307

Monday-Friday: 9am to 6pm

Saturday, Sunday: Closed

Jiangyin Lonovae Tenology Co., Ltd. was founded in 2015, in Jiangyin city, China, occupied an area of 3,000 square metre, more than 100 staffs, Specialized in Plastic Manufacturing, focus on Returnable Transport Packaging solutions for various industries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Future Leading PP Coaming Box Supplier for Tomorrow's Sustainable and Customized Solutions here

News-ID: 4244209 • Views: …

More Releases from Jiangyin Lonovae Technology Co., Ltd.,

Your Guide to Manure Removal: How to Find a High-Quality Manure Collection Belt …

When it comes to running an efficient and sustainable farm, proper manure management is one of the most important considerations. Whether on a dairy, poultry, or livestock farm, effective manure removal is essential not only for maintaining cleanliness and hygiene but also for ensuring the health of both animals and workers. One of the most efficient and cost-effective solutions to this challenge is the use of high-quality manure collection belts.…

Why Lonovae, the China Top Sleeve Pack Containers Supplier, is Key to Unlocking …

I. Introduction: Defining Excellence in Returnable Transport

The operational landscape of global logistics is undergoing a fundamental transformation, demanding packaging solutions that are not only robust and cost-efficient but also aligned with stringent global sustainability goals. In this high-stakes environment, Returnable Transport Packaging (RTP) has emerged as the clear path forward, and companies specializing in advanced polymer engineering are leading the revolution. At the forefront of this movement is Jiangyin Lonovae…

Why Lonovae is a China Top Sleeve Pack Manufacturer: A Look at Its Leading Quali …

I. Introduction: The Era of Durable and Sustainable Logistics

The global supply chain is rapidly demanding packaging solutions that are not merely functional but fundamentally sustainable, durable, and cost-efficient over the long term. This pivot away from disposable materials toward high-performance Returnable Transport Packaging (RTP) is defining the future of industrial logistics. At the heart of this transformation, driving innovation in material science and efficiency, is Jiangyin Lonovae Technology Co., Ltd.

Since…

Manure Removal Made Easy: Your Guide to Belts from a China Top Manure Removal Be …

Effective manure management is an essential aspect of maintaining farm hygiene, animal welfare, and overall productivity in the agriculture industry. Whether on dairy farms, poultry operations, or large-scale livestock facilities, keeping animal enclosures clean can be a labor-intensive and time-consuming process. However, technological advancements in conveyor systems, particularly in manure removal, are making this task much easier. Jiangyin Lonovae Technology Co., Ltd., a China Top Manure Removal Belts Manufacturer(https://www.lonovae.com/), is…

More Releases for RTP

Plastic Compounding Market Comprehensive study by Key Players: Solvay, DowDuPont …

HTF MI Analyst have added a new research study on Title Global Plastic Compounding Market Growth 2021-2026 with detailed information of Product Types [PP Compounds, PE Compounds, PVC Compounds, PA Compounds & Others], Applications [Automotive, Building & Construction, Electronics & Appliances, Consumer Goods, Packaging & Others] & Key Players Such as LyondellBasell, SABIC, BASF, Solvay, DowDuPont, RTP, Mitsui Chemicals, ExxonMobil, Mexichem, Westlake Chemical, Chevron Phillips Chemical, Ineos Styrolution, Total Petrochemicals,…

Molded Interconnect Devices Market Trend, Revenue & Regional Analysis 2024 By To …

With the advent of an increasing number of consumer device applications, the global molded interconnect devices market is expected to experience a substantial growth rate in the forthcoming years. The primary factor driving the industry would undeniably be the ability of the molded interconnect devices' to integrate several mechanical & electrical functions in consumer devices while also enabling the reduction of circuit density & facilitating product miniaturization. Moreover, the devices…

What’s Driving the Molded Interconnect Devices Market Trends? Key Companies - …

The Molded Interconnect Devices market has witnessed growth from USD XX million to USD XX million from 2014 to 2019. With the CAGR of X.X%, this market is estimated to reach USD XX million in 2026.

The report mainly studies the size, recent trends and development status of the Molded Interconnect Devices market, as well as investment opportunities, government policy, market dynamics (drivers, restraints, opportunities), supply chain and competitive landscape. Technological…

What’s Driving the Molded Interconnect Devices Market Trends? Key Companies - …

Molded Interconnect Devices Market is expected to reach USD 840 million by 2024. The proliferation of the smart & connected wearable devices across the globe is driving the industry growth. These components allow lesser energy consumption and help in enhancing the battery life of the wearable devices, which is beneficial to the users. Moreover, these components further help in reducing the overall of the wearable devices. The wearables are increasingly…

Global Polyetherimide(PEI) Market 2019 - SABIC, RTP, Ensinger, Mitsuichemicals

This new report by Eon Market Research, titled “Global Polyetherimide(PEI) Market 2019 Research Report, 2015 – 2025” offers a comprehensive analysis of Polyetherimide(PEI) industry at a global as well as regional and country level. Key facts analyzed in this report include the Polyetherimide(PEI) market size by players, regions, product types and end industries, history data 2014-2018 and forecast data 2019-2025. This report primarily focuses on the study of the competitive…

Polyetherimide(PEI) Market 2017- SABIC, RTP, Ensinger, Mitsuichemicals

Apex Research, recently published a detailed market research study focused on the "Polyetherimide(PEI) Market" across the global, regional and country level. The report provides 360° analysis of "Polyetherimide(PEI) Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Polyetherimide(PEI) industry, and estimates the future trend of Polyetherimide(PEI) market on the basis of…