Press release

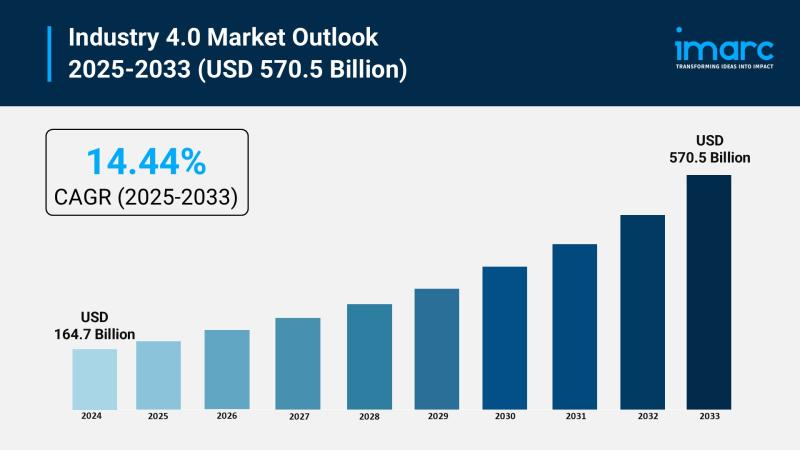

Industry 4.0 Market Size to Hit USD 570.5 Billion by 2033 | With a 14.44% CAGR

Market Overview:The industry 4.0 market is experiencing rapid growth, driven by accelerated digital transformation across verticals, proactive government initiatives and strategic support, and increasing adoption of industrial robotics and automation. According to IMARC Group's latest research publication, "Industry 4.0 Market Size, Share, Trends and Forecast by Component, Technology Type, End Use Industry, and Region, 2025-2033." The global industry 4.0 market size reached USD 164.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 570.5 Billion by 2033, exhibiting a growth rate (CAGR) of 14.44% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Download a sample PDF of this report: https://www.imarcgroup.com/industry-4-0-market/requestsample

Our report includes:

● Market Dynamics

● Market Trends and Market Outlook

● Competitive Analysis

● Industry Segmentation

● Strategic Recommendations

Growth Factors in the Industry 4.0 Market

● Accelerated Digital Transformation Across Verticals

The imperative for operational efficiency and productivity improvements is a primary catalyst driving the global Industry 4.0 market. Companies across major verticals like manufacturing, automotive, and energy are making substantial investments to integrate smart technologies, moving from traditional to digitally-enabled processes. For instance, the manufacturing sector dominates market adoption, driven by the deployment of smart factory solutions, industrial robotics, and real-time data analytics to enhance throughput and reduce unplanned downtime. A global technology company, for example, successfully increased its operational efficiency by $15%$ in a smart factory in France by installing AI-enabled Industrial Internet of Things (IIoT) systems. This focus on maximizing value while minimizing waste through technologies like AI and IoT is the core commercial driver propelling market expansion.

● Proactive Government Initiatives and Strategic Support

Strategic support and funding from governments worldwide are significantly accelerating the adoption of Industry 4.0 concepts. Nations are launching national programs to boost manufacturing competitiveness through digitalization. For example, a major Asian country's Ministry of Heavy Industries is spearheading a national mission to promote Industry 4.0 adoption, focusing on establishing Centers of Excellence to support and demonstrate advanced technologies like automation and data analytics. This initiative provides a vital push for Micro, Small, and Medium Enterprises (MSMEs) to upgrade their processes and stay competitive. Similar initiatives in European nations encourage the integration of IIoT, robotics, and edge computing, illustrating a concerted global effort to modernize industrial production.

● Increasing Adoption of Industrial Robotics and Automation

The increasing integration of industrial robots and automation technologies is a key factor fueling the Industry 4.0 market. Manufacturers are embracing robotics to perform repetitive tasks, improve precision, and achieve higher quality assurance. Recent data from the International Federation of Robotics (IFR) highlighted a substantial increase in the operational stock of industrial robots globally, demonstrating the rapid acceptance of this technology within the manufacturing sector. This surge is not merely about replacing human labor but leveraging programmable, automatically controlled manipulators to streamline production lines and enable mass customization. The automotive sector, in particular, shows a high propensity for advanced automation, using smart machines to track production equipment and preemptively detect issues.

Key Trends in the Industry 4.0 Market

● The Rise of Digital Twins for Simulation and Optimization

The creation of "Digital Twins" is an emergent and transformative trend in the Industry 4.0 landscape. A Digital Twin is a precise, real-time virtual replica of a physical asset, process, or system, such as a factory floor or a piece of industrial equipment. This technology leverages Industrial IoT data to enable real-time monitoring, deep analysis, and predictive simulation. For instance, a major global technology company emphasizes the necessity of continuously investing to keep its Digital Twin solutions synchronized with their evolving physical counterparts, illustrating the value of this high-fidelity replication. This capability allows engineers to test process changes, anticipate equipment failures through predictive maintenance, and optimize performance in the virtual world before deployment, significantly reducing risk and enhancing decision-making across manufacturing, healthcare, and transportation sectors.

● Integration of 5G and Edge Computing for Low-Latency Operations

The deployment of 5G and Edge Computing is fundamentally changing how data is processed within industrial environments, a critical trend for real-time Industry 4.0 applications. Edge computing processes data closer to the source-at the machine level-rather than relying solely on the cloud. This significantly reduces latency, a necessity for instantaneous decision-making in high-speed, automated processes. The rollout of 5G, with its enhanced connectivity, further supports this by enabling a massive increase in the number of connected devices and the speed of data exchange. For example, certain large industrial companies are applying 5G and edge computing to improve global connectivity and enable faster data exchange, thereby ensuring optimal safety and operational excellence, even in remote environments. This combination is essential for coordinating autonomous systems and real-time quality control.

● The Application of Additive Manufacturing (3D Printing) for Customization

Additive Manufacturing, commonly known as 3D printing, is shifting from a prototyping tool to a core production method in the Industry 4.0 era, particularly enabling personalization and just-in-time production. This trend allows manufacturers to print complex three-dimensional objects layer-by-layer directly from digital models, supporting the goal of economical "lot size of one" production. In the healthcare sector, a leading 3D printing solutions provider offers technology that enables the development of highly realistic, patient-specific anatomical models for medical training and planning. This showcases how the technology is pioneering personalized medicine and enhancing the efficiency of medical equipment production. The ability to rapidly create specialized, low-volume components simplifies product design and allows for swift adaptation to changing customer needs.

Ask analyst of customized report: https://www.imarcgroup.com/request?type=report&id=6062&flag=E

Leading Companies Operating in the Industry 4.0 Industry:

● Cisco Systems Inc.

● DENSO Corporation

● Fanuc Corporation

● Hewlett Packard Enterprise Company

● Intel Corporation

● International Business Machines Corporation

● Nvidia Corporation

● Robert Bosch GmbH

● SAP SE

● Schneider Electric SE

● Stratasys Ltd.

● Swisslog Holding AG (Kuka AG)

● Techman Robot Inc. (Quanta Storage Inc.)

Industry 4.0 Market Report Segmentation:

By Component:

● Hardware

● Software

● Services

Hardware leads the market with around 49.8% share in 2024, serving as the physical backbone of Industry 4.0 through devices like industrial robots and sensors that collect real-time data for decision-making.

By Technology Type:

● Industrial Robotics

● Industrial IoT

● AI and ML

● Blockchain

● Extended Reality

● Digital Twin

● 3D Printing

● Others

Industrial IoT dominates with a 27.5% market share in 2024, enabling industries to gather extensive data for optimization and decision-making, with the market predicted to grow significantly by 2032.

By End Use Industry:

● Manufacturing

● Automotive

● Oil and Gas

● Energy and Utilities

● Electronic and Foundry

● Food and Beverages

● Aerospace and Defense

● Others

Manufacturing holds a 31.4% market share in 2024, as manufacturers adopt Industry 4.0 to enhance efficiency, reduce costs, and improve supply chain management through interconnected smart factories.

Regional Insights:

● North America (United States, Canada)

● Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

● Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

● Latin America (Brazil, Mexico, Others)

● Middle East and Africa

Europe accounts for over 35.8% of the market in 2024, driven by early adoption of Industry 4.0 technologies and strong government support for digitalization and sustainability initiatives.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industry 4.0 Market Size to Hit USD 570.5 Billion by 2033 | With a 14.44% CAGR here

News-ID: 4243103 • Views: …

More Releases from IMARC Group

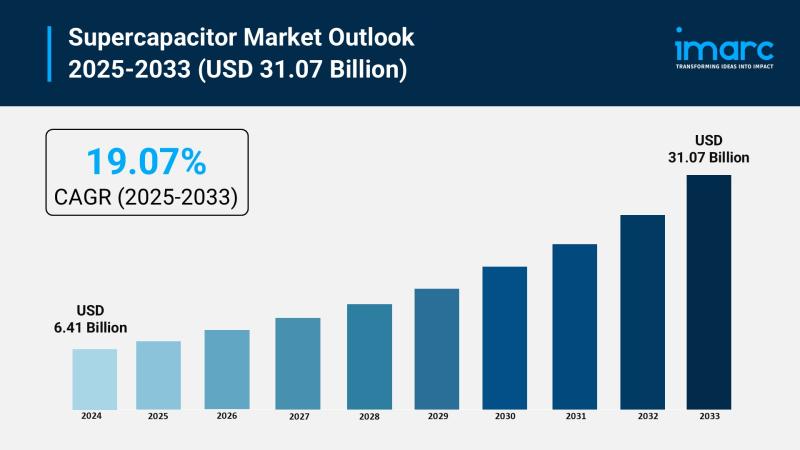

Supercapacitor Market Size to Reach $31.07B by 2033: Trends & Opportunities

Market Overview:

The supercapacitor market is experiencing rapid growth, driven by electrification of automotive systems, renewable energy and grid stabilization, and expansion of industrial automation and robotics. According to IMARC Group's latest research publication, "Supercapacitor Market Size, Share, Trends and Forecast by Product Type, Module Type, Material Type, End Use Industry, and Region, 2025-2033", the global supercapacitor market size was valued at USD 6.41 Billion in 2024. Looking forward, IMARC Group…

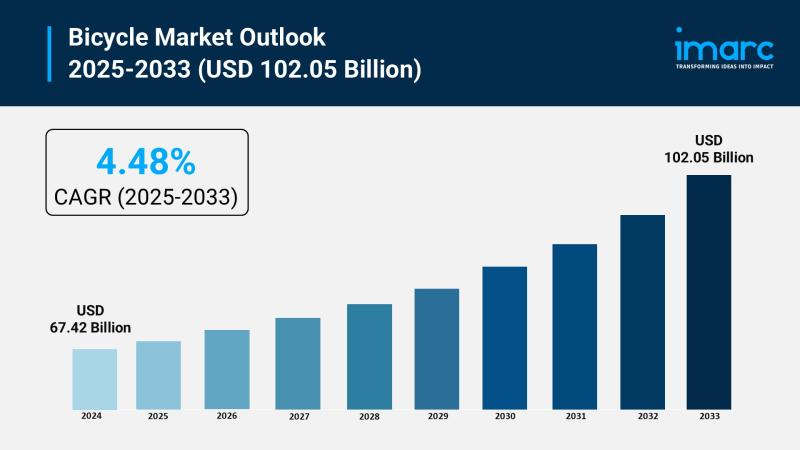

Bicycle Market Size to Surpass $102.05B by 2033: Growth & Insights

Market Overview:

The bicycle market is experiencing rapid growth, driven by global expansion of cycling infrastructure, rising health consciousness and preventative wellness, and technological advancements in e-bike propulsion. According to IMARC Group's latest research publication, "Bicycle Market Size, Share, Trends and Forecast by Type, Technology, Price, Distribution Channel, End User, and Region, 2025-2033", The global bicycle market size was valued at USD 67.42 Billion in 2024. Looking forward, IMARC Group estimates…

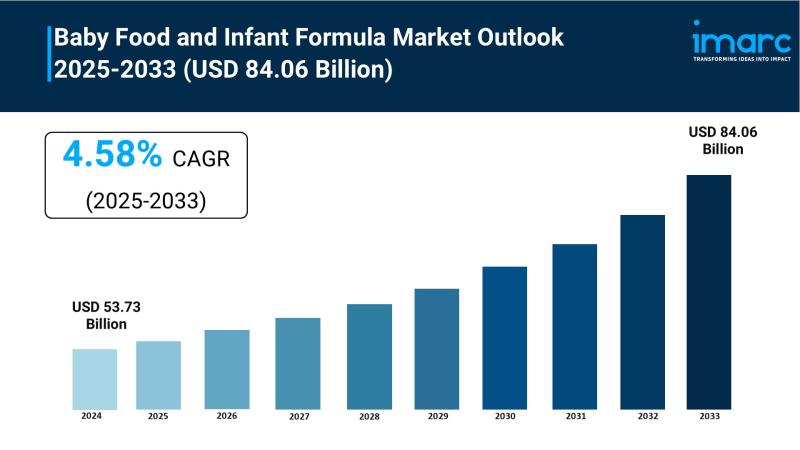

Baby Food and Infant Formula Market to Reach USD 84.06 Billion by 2033, Growing …

Market Overview:

The Baby Food and Infant Formula Market is experiencing steady expansion, driven by Increasing Awareness of Nutritional Needs for Infants, Rising Number of Working Women, and Technological Advancements and Product Innovation. According to IMARC Group's latest research publication, "Baby Food and Infant Formula Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global baby food and infant formula market size reached USD 53.73 Billion in 2024.…

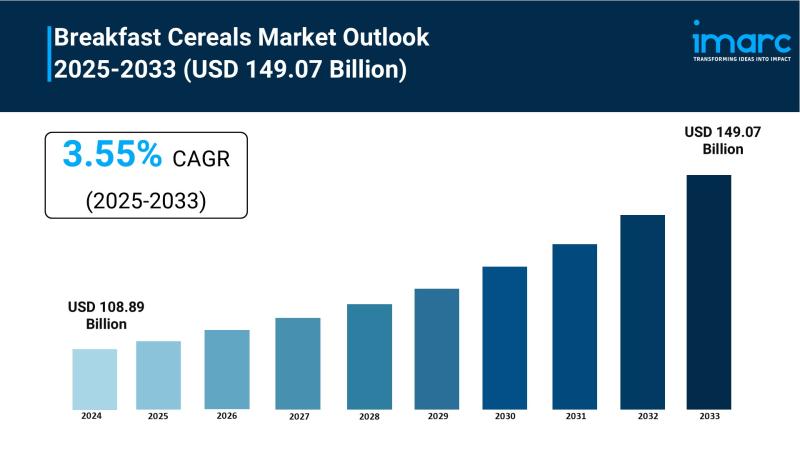

Breakfast Cereals Market to Reach USD 149.07 Billion by 2033, Growing at a CAGR …

Market Overview:

The Breakfast Cereals Market is experiencing rapid growth, driven by Health and Wellness Awareness, Busy Lifestyles and On-the-Go Demand and Rising Disposable Incomes and Global Market Expansion . According to IMARC Group's latest research publication, "Breakfast Cereals Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global breakfast cereals market size was valued at USD 108.89 Billion in 2024. Looking forward, IMARC Group estimates…

More Releases for Industry

Hydro Lubricants Market Size, Analysis, and Forecast Report 2018 to 2026(By Indu …

The rising demand for hydro lubricants from manufacturing sector is also multiplying at a faster rate, on the back of their competency in upgrading the service-life of machinery. The hydro lubricants market is primarily driven on account of its low-friction attributes, which makes it highly likely to outshine the synthetic variants. Moreover, the demand for hydro lubricants for machinery assemblies is on the rise, as they facilitate in minimizing…

Hydro Lubricants Market Insights, Trends & Future Development Status Recorded du …

The rising demand for hydro lubricants from manufacturing sector is also multiplying at a faster rate, on the back of their competency in upgrading the service-life of machinery. The hydro lubricants market is primarily driven on account of its low-friction attributes, which makes it highly likely to outshine the synthetic variants. Moreover, the demand for hydro lubricants for machinery assemblies is on the rise, as they facilitate in minimizing…

Global Pyrite Market 2019 | Applications: Jewelry Industry, Sulfur Compounds Ind …

The major factor driving the pyrite market is the rising demand of jewelry and sulfur compounds market. This report researches the worldwide Pyrite market size (value, capacity, production, and consumption) in key regions like North America, Europe, Asia Pacific (China, Japan) and other regions. This study categorizes the global Pyrite breakdown data by manufacturers, region, type, and application, also analyzes the market status, market share, growth rate, future trends, market…

Lipase Enzymes Market Future Forecast Indicates Impressive Growth Rate (Segmenta …

Market Outlook

Increased consumption of processed food and dairy products among consumers has fuelled the demand and supply of lipase enzymes over the years. Lipase is an enzyme that catalyzes the hydrolytic reaction of fats, and reduces the formation of glycerol and fatty acids in all living organisms. It plays a vital role in the process of digestion by transporting and processing the ester bonds in triglycerides. Due to the varied…

Big Bag Connection System Market Segmented By technology Automatic, Semi-Automat …

Global Big Bag Connection System Market: An Overview

The key advancement in automation encourages manufacturers to adopt smart systems to increase productivity and to facilitate timely production. Owing to the perception of consumers as well as manufacturers regarding health and hygiene of product, the big bag connection system market is anticipated to propel during the forecast period. Big bag connection system ensure dust -free docking of big bags and provide flexibility…

Europe Plastic Pallet Market Size, Shares, Forecast Report 2016 : Food Industry, …

This report studies sales (consumption) of Plastic Pallet in Europe market, especially in Germany, UK, France, Russia, Italy, Benelux and Spain, focuses on top players in these countries, with sales, price, revenue and market share for each player in these Countries, covering

ShangHai Pallet Plastic Industry Co., Ltd.

Shanghai Lika Plastic Manufacturing Co., Ltd.

Guangzhou Plastic Industrial Corporation Ltd

Shandong Liyang Plastic Molding Co.,Ltd

Xinding Plastic

ZheJiang Primacy Plastic Industry Co., Ltd

Shanghai Qinghao Plastic Pallet Manufacture…