Press release

Sausage Manufacturing Plant Project Report 2025

The sausage industry has become one of the fastest-growing segments in the processed meat and ready-to-eat food sector, supported by increasing consumer demand across global markets. Setting up a sausage manufacturing plant requires more than just infrastructure; it involves strategic planning, investment, efficient equipment, and strong market awareness. This article presents an overview of sausage manufacturing plants, covering setup, production stages, market trends, investment considerations, and operational requirements.What is Sausage?

Sausage holds a significant position in the global processed meat market due to its taste, convenience, versatility, and cultural significance across diverse cuisines. These products are manufactured by grinding meat (pork, beef, chicken, turkey, or plant-based alternatives), mixing with spices, seasonings, and preservatives, and stuffing into casings made from natural or synthetic materials. Available in various types including fresh sausages, cooked sausages, smoked sausages, dry-cured varieties, and specialty regional products like bratwurst, chorizo, salami, and pepperoni, sausages serve both household consumption and foodservice applications. The growing popularity of convenience foods, breakfast items, and ready-to-cook meat products has driven demand for diverse sausage varieties in retail and commercial kitchens. Consumer preferences are increasingly shifting toward premium quality, artisanal flavors, organic options, reduced-sodium formulations, and plant-based alternatives, while regulatory bodies emphasize food safety standards, accurate labeling, hygiene practices, and traceability to ensure consumer protection and product quality.

Request a Sample Report: https://www.imarcgroup.com/sausage-manufacturing-plant-project-report/requestsample

What is Driving the Sausage Market?

The sausage market is primarily driven by rising demand for convenient, ready-to-eat, and easy-to-prepare protein-rich food products that align with busy modern lifestyles. Growing urbanization, increasing working population, and changing dietary habits have accelerated consumption of processed meat products across households and quick-service restaurants. The expanding foodservice industry, including fast-food chains, cafes, and catering services, has created substantial demand for sausages as breakfast items, snacks, and meal components. Population growth, rising disposable incomes, and improved cold-chain infrastructure in emerging economies support market expansion. Product innovation focusing on new flavors, ethnic varieties, health-conscious formulations (low-fat, reduced-sodium, nitrate-free), and plant-based alternatives is attracting diverse consumer segments. The influence of Western food culture, globalization of culinary preferences, and growth of organized retail and supermarkets have increased product accessibility and visibility. E-commerce platforms and online grocery delivery services have enhanced distribution reach. Additionally, growing consumer interest in premium, artisanal, and locally-sourced meat products, coupled with advancements in packaging technology for extended shelf life, continues to fuel market growth, aligning the industry with evolving food consumption patterns and quality expectations.

Understanding Sausage Manufacturing

• Sausage manufacturing refers to the processing, formulation, and production of meat-based or plant-based sausage products through grinding, mixing, stuffing, cooking, smoking, and packaging operations.

• Production activities include raw material preparation, meat grinding and emulsification, seasoning and ingredient mixing, casing preparation, stuffing, linking, cooking or smoking, cooling, packaging, and labeling.

• Meat products are highly perishable and temperature-sensitive; therefore, strict cold-chain management, hygiene protocols, and food safety measures are vital.

• Efficiency in the process ensures consistent quality, compliance with food safety regulations, desirable taste and texture, and adequate shelf life for domestic and export markets.

Key Components of a Business Plan

• Executive Summary: Outlines vision, mission, and business objectives.

• Market Research: Identifies demand patterns, consumer behavior, and competitive players.

• Operational Strategy: Includes plant design, capacity, workflow, and quality assurance measures.

• Marketing and Sales Plan: Defines distribution channels, branding, and positioning in domestic and export markets.

• Financial Planning: Covers projected investments, cost structures, and revenue expectations.

• Risk Assessment: Evaluates potential challenges such as raw material supply, regulatory compliance, and market fluctuations.

Capital Investment Overview

CapEx (Capital Expenditure):

• Land acquisition, plant construction, utilities setup, and equipment purchase.

• One-time costs associated with establishing infrastructure and ensuring production efficiency.

• Defines long-term productivity and competitiveness.

OpEx (Operating Expenditure):

• Recurring costs including labor, utilities, packaging, storage, and transportation.

• Raw material procurement and regular equipment maintenance.

• Compliance with safety certifications, hygiene practices, and quality control standards.

Machinery and Equipment Requirements

Primary Equipment:

• Meat grinders and bowl cutters for size reduction and emulsification.

• Mixing machines for uniform blending of meat, spices, and additives.

• Vacuum fillers and stuffing machines for casing filling.

• Linking and portioning equipment for uniform sausage sizing.

• Cooking systems including steam cookers, water baths, and ovens.

• Smoking chambers for flavor development and preservation.

• Chilling and cooling tunnels for temperature control post-processing.

• Vacuum packaging and modified atmosphere packaging (MAP) machines.

• Metal detectors and quality inspection systems.

Supporting Equipment:

• Cold storage facilities and blast freezers for raw materials and finished products.

• Casing preparation and conditioning equipment.

• Conveyors and transfer systems for material movement.

• Water treatment and effluent management systems.

• Cleaning-in-place (CIP) systems for sanitation.

Buy Report Now: https://www.imarcgroup.com/checkout?id=13078&method=1911

Operating Costs

• Procurement of fresh or frozen meat from slaughterhouses and meat suppliers.

• Labor salaries, training, and workforce management.

• Utilities such as electricity, water, refrigeration, and steam generation.

• Maintenance and servicing of machinery and equipment.

• Packaging materials including casings, vacuum pouches, labels, and cartons.

• Spices, seasonings, preservatives, and curing agents.

• Transportation and cold-chain distribution logistics.

• Certification, compliance, and quality assurance activities.

Raw Materials

• Main Raw Materials: Fresh or frozen meat including pork, beef, chicken, turkey, lamb, or plant-based protein alternatives (soy, pea protein, wheat gluten).

• Additional Inputs: Natural or artificial casings (collagen, cellulose, or animal intestines), spices, salt, curing salts (nitrites/nitrates), binders, emulsifiers, and flavor enhancers.

• Packaging Materials: Vacuum pouches, shrink wraps, plastic casings, labels, trays, and shipping cartons.

• Supply Considerations: Consistency of meat quality, reliable sourcing partnerships, cold-chain integrity, adherence to food safety standards, and certifications for halal, kosher, or organic products where applicable.

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=13078&flag=C

Frequently Asked Questions (FAQs)

1. What is the first step in setting up a sausage manufacturing plant?

The process begins with developing a business plan, securing land, obtaining licenses from food safety authorities (such as FSSAI, USDA, or local health departments), and identifying reliable meat suppliers and cold-chain logistics partners.

2. Why is cold-chain management considered critical?

Cold-chain management ensures product freshness, prevents microbial growth and spoilage, maintains food safety standards, and extends shelf life for distribution to domestic and international markets.

3. Can sausage manufacturing plants focus only on domestic markets?

Yes, though many manufacturers also target exports, as international markets often demand high-quality, certified processed meat products meeting specific food safety and religious certification requirements.

4. How does automation benefit sausage manufacturing?

Automation improves production speed, ensures consistent product sizing and quality, reduces contamination risks, lowers dependency on manual labor, and enhances operational efficiency and hygiene standards.

5. Is backward integration into meat processing necessary?

Not mandatory; many sausage manufacturers rely on partnerships with slaughterhouses, meat processors, and cold storage facilities for consistent raw material supply and quality assurance.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Sausage Manufacturing Plant Project Report 2025 here

News-ID: 4223090 • Views: …

More Releases from IMARC Group

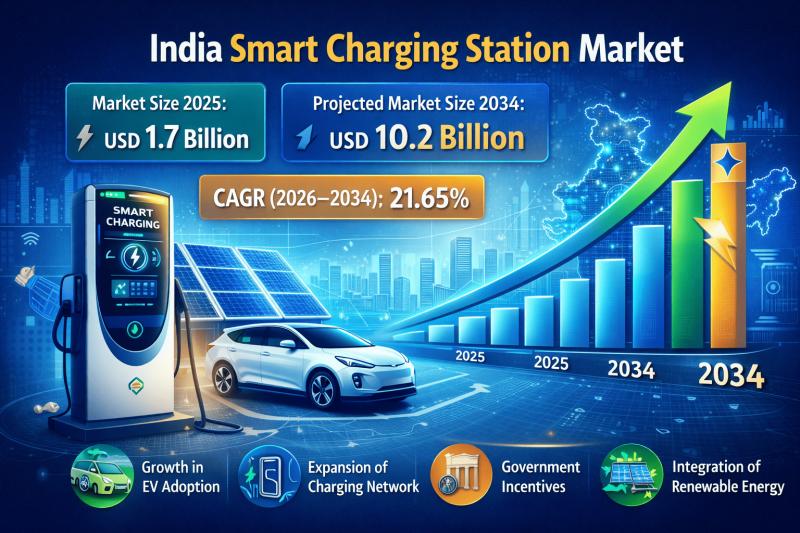

India Smart Charging Station Market Expected to Reach USD 10.2 Billion by 2034, …

IMARC Group's latest research publication "India Smart Charging Station Market Size, Share, Trends and Forecast by Charging Technology, Connectivity, Battery Technology, Application, and Region, 2026-2034" the India smart charging station market size reached USD 1.7 Billion in 2025. The market is expected to reach USD 10.2 Billion by 2034, exhibiting a growth rate (CAGR) of 21.65% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-smart-charging-station-market/requestsample

What is a Smart Charging Station?

A smart charging station…

India Home Diagnostic Testing Market Expected to Reach USD 332.6 Million by 2034 …

IMARC Group's latest research publication "India Home Diagnostic Testing Market Size, Share, Trends and Forecast by Test Type, Form, Distribution Channel, and Region, 2026-2034" the India home diagnostic testing market size reached USD 222.7 Million in 2025. The market is expected to reach USD 332.6 Million by 2034, exhibiting a growth rate (CAGR) of 4.56% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-home-diagnostic-testing-market/requestsample

What is Home Diagnostic Testing?

Home diagnostic testing refers to medical…

India Catering Services Market Expected to Reach USD 7.7 Billion by 2034, Indust …

Report Introduction

According to IMARC Group's latest report titled "India Catering Services Market Size, Share, Trends and Forecast by Service Type, End-User, and Region, 2026-2034", the study offers a granular analysis of the nation's burgeoning food service and hospitality sectors. The study offers a profound analysis of the industry, encompassing India catering services market research report, share, size, growth factors, key trends, and regional insights. The report covers critical market dynamics,…

India Smart Home Lighting Market Expected to Reach USD 9,991.3 Million by 2034, …

According to recent reports by IMARC Group, the India smart home lighting market is witnessing rapid growth as consumers increasingly adopt energy-efficient and automated living solutions.

Request Sample Link: https://www.imarcgroup.com/india-smart-home-lighting-market/requestsample

Market Overview and Statistics

✤ Current Market Size (2025): The India smart lighting market reached a value of USD 1,032.1 Million in 2025.

✤ Projected Market Size (2034): It is expected to grow to USD 9,991.3 Million by 2034.

✤ Growth Rate (CAGR): The market…

More Releases for Sausage

Prominent Collagen Sausage Casings Market Trend for 2025: Automation Innovations …

"How Are the key drivers contributing to the expansion of the collagen sausage casings market?

The escalating need for processed foods is predicted to fuel the expansion of the collagen sausage casings industry. The term 'processed foods' encompasses any edibles modified from their original state through various methods aimed at improving shelf life, flavor, texture, appearance, or convenience. Their increasing demand attributes to their long shelf life, affordability, and convenience, making…

Automatic Sausage Tying Machine: Easy Sausage Making

Sausage making is a job that requires patience and skill, but with the automatic sausage tying machine, it all becomes easier. This equipment can not only reduce the labour intensity of workers, but also greatly improve the production efficiency. Let's take a look at its features and functions!

Image: https://www.yingzemachinery.com/uploads/%E9%A6%99%E8%82%A0%E8%87%AA%E5%8A%A8%E6%89%8E%E5%8F%A3%E6%9C%BA%E5%8F%82%E6%95%B0.png

1,Reduce the burden of workers:

It is very simple to operate this machine, just put the filled sausages into the feeding port and…

Sausage Market Size 2024 to 2031.

Market Overview and Report Coverage

A sausage is a popular food item made from ground meat mixed with various ingredients, seasonings, and spices, encased in a casing and typically grilled, fried, or boiled before eating.

The global sausage market is expected to grow at a compound annual growth rate (CAGR) of 3.80% during the forecasted period. The future outlook for the sausage market appears promising, driven by the increasing demand…

Global Pepperoni Foods Market: Emerging Trends, Major Key Players Ezzo Sausage C …

According to the report, the global Pepperoni Foods market size is expected to grow at a CAGR of more than 4% from 2021 to 2028. The demand for pepperoni is driven by its health benefits. Pepperoni contains high levels of protein and has a high nutritional value. This high content of protein results in a satiating effect, which helps to reduce hunger pangs. This also leads to a reduction in…

Global Plant-based Dry Sausage (Vegan Dry Sausage) Market Expected to Witness a …

LP INFORMATION recently released a research report on the Plant-based Dry Sausage (Vegan Dry Sausage) market analysis, which studies the Electrical Cord Reels's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global “Plant-based Dry Sausage (Vegan Dry Sausage) Market 2020-2025” Research Report categorizes the global Plant-based Dry Sausage (Vegan Dry Sausage) market by key players, product type, applications and regions,etc. The…

Chicken Sausage Market Key Player Analysis By - Applegate, Shuanghui, Dietz & Wa …

The recent research report on the global Chicken Sausage market presents the latest industry data and future trends, allowing you to recognize the products and end users driving Revenue growth and profitability of the market.

The report offers an extensive analysis of key drivers, leading market players, key segments, and regions. Besides this, the experts have deeply studied different geographical areas and presented a competitive scenario to assist new entrants, leading…