Press release

PUF Panel Manufacturing Plant Setup Report 2025: Industry Trends, Machinery and Cost Breakdown

Setting up a PUF panel manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "PUF Panel Manufacturing Plant Setup Cost 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a PUF panel manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Request for a Sample Report: https://www.imarcgroup.com/puf-panel-manufacturing-plant-project-report/requestsample

Product Overview

A PUF panel manufacturing plant is a specialized processing facility designed to produce polyurethane foam (PUF) insulated panels, also known as sandwich panels or insulated panels. The process typically begins with high-quality raw material sourcing, including polyol, isocyanate, catalysts, and metal sheets (galvanized steel, aluminum, or stainless steel), followed by surface preparation and coating. The continuous or discontinuous lamination process involves injecting liquid polyurethane foam between two metal facings using advanced foaming and pressing machines to achieve consistent density, thickness, and insulation properties. Depending on production requirements, the plant can produce various panel types including wall panels, roof panels, cold storage panels, or customized variants to meet diverse applications. PUF panels are widely used in cold storage facilities, warehouses, food processing units, pharmaceutical industries, cleanrooms, and modular construction due to their excellent thermal insulation, structural strength, and energy efficiency. The plant is equipped with machinery for metal profiling, foam injection, continuous lamination, cutting, and packaging to ensure that quality and safety standards are maintained. Automation, quality control systems, and fire safety certifications play an important role in modern PUF panel manufacturing plants. Additionally, efficient packaging solutions are employed to prevent damage during transportation, facilitate handling, and support wholesale or retail distribution. With increasing demand for energy-efficient construction materials and cold chain infrastructure, PUF panel plants are adopting sustainable practices, advanced technology, and cost-effective operations to meet rapidly growing industrial and commercial needs.

Market Drivers

The PUF panel manufacturing plant market is being driven by the growing demand for energy-efficient, durable, and versatile construction materials worldwide. Industries are rapidly moving towards sustainable building solutions, temperature-controlled infrastructure, and prefabricated construction, making PUF panels a popular choice over traditional building materials. Their superior properties of thermal insulation, fire resistance, lightweight structure, moisture resistance, and structural integrity position them as an ideal component for cold storage facilities, industrial warehouses, food processing plants, pharmaceutical units, and commercial buildings. In addition, the rapidly growing cold chain logistics sector and increasing investments in food preservation infrastructure are further increasing the consumption of PUF panel-based products. The construction and real estate industry is also demanding, as PUF panels are widely used for their quick installation and energy-saving properties in modular and pre-engineered buildings. Furthermore, awareness about energy conservation, green building initiatives, urbanization, and stringent building code regulations is expanding the consumer base for PUF panels. Technological advancements in foam technology, panel design, and manufacturing automation have improved efficiency and scalability in production, making it more accessible to both large manufacturers and small enterprises. In addition, government support for energy-efficient construction industries, growing trends of sustainable infrastructure development, and cold storage expansion are creating attractive opportunities for investing in PUF panel manufacturing plants, positioning the industry for strong growth in the coming years.

Buy Now: https://www.imarcgroup.com/checkout?id=14949&method=1911

Key Steps Required to Set Up a PUF Panel Plant

1. Market Analysis

The report provides insights into the landscape of the PUF panel industry at the global level. The report also provides a segment-wise and region-wise breakup of the global PUF panel industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of PUF panels, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the PUF panel manufacturing plant project is elaborated in the report.

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for PUF panel manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for PUF panel production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a PUF panel manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=14949&flag=C

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release PUF Panel Manufacturing Plant Setup Report 2025: Industry Trends, Machinery and Cost Breakdown here

News-ID: 4222354 • Views: …

More Releases from IMARC Group

Singapore Travel And Tourism Market Expected to Reach USD 6.9 Billion by 2034, I …

IMARC Group's latest research publication "Singapore Travel and Tourism Market Size, Share, Trends and Forecast by Type, Service Offering, Purpose of Visit, Booking Type, and Region, 2026-2034" the Singapore travel and tourism market size reached USD 4.7 Billion in 2025. The market is expected to reach USD 6.9 Billion by 2034, exhibiting a growth rate (CAGR) of 4.28% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/singapore-travel-tourism-market/requestsample

What is Travel and Tourism?

Travel and tourism…

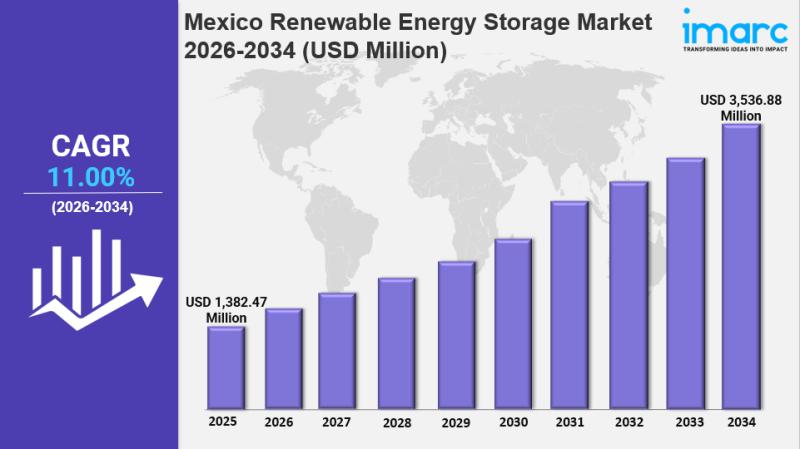

Mexico Renewable Energy Storage Market Size, Growth, Latest Trends and Forecast …

IMARC Group has recently released a new research study titled "Mexico Renewable Energy Storage Market Size, Share, Trends and Forecast by Source, Technology, Application, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Renewable Energy Storage Market Overview:

The Mexico renewable energy storage market reached USD 1,382.47 Million in 2025. The market is projected…

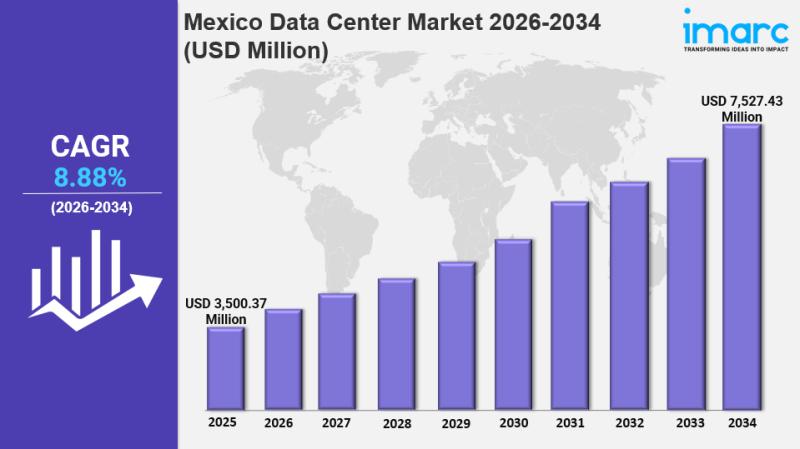

Mexico Data Center Market Size, Trends, Growth and Forecast 2026-2034

IMARC Group has recently released a new research study titled "Mexico Data Center Market Size, Share, Trends and Forecast by Component, Type, Enterprise Size, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Data Center Market Summary:

The Mexico data center market size was valued at USD 3,500.37 Million in 2025 and…

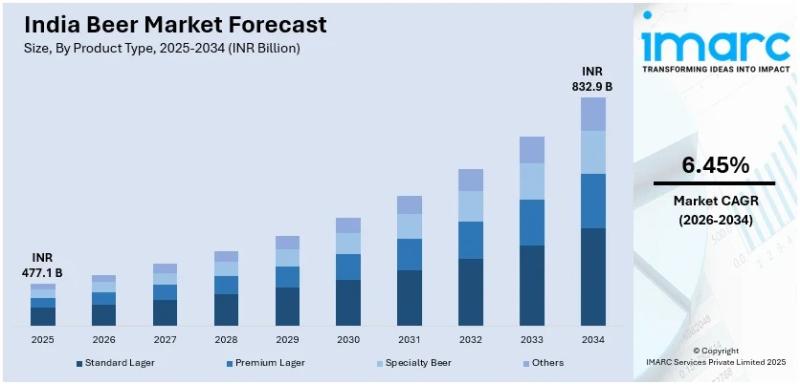

India Beer Market to Reach INR 832.93 Billion by 2034: Industry Size, Share, Tre …

Delhi, India - 19 Feb 2026

Summary

The India beer market size reached INR 477.05 Billion in 2025, according to the latest comprehensive industry analysis by IMARC Group. Driven by rapid urbanization, an expanding young demographic, and a surging cultural shift toward premium and craft beverages, the market is projected to reach INR 832.93 Billion by 2034. This represents a steady compound annual growth rate (CAGR) of 6.45% during the forecast period…

More Releases for PUF

PUF Panel Market Demand Analysis Report 2026

On Dec 16, the latest report "Global PUF Panel Market 2026 by Manufacturers, Regions, Types and Applications, Forecast to 2032" from Global Info Research provides a detailed and comprehensive analysis of the global PUF Panel market. The report provides both quantitative and qualitative analysis by manufacturers, regions and countries, types and applications. As the market is constantly changing, this report explores market competition, supply and demand trends, and key factors…

PUF Panel Manufacturing Plant Setup Cost 2025: Machinery Requirements and Projec …

PUF (Polyurethane Foam) panels are insulated building materials made by injecting rigid polyurethane foam between two metal sheets, typically pre-coated galvanized iron or aluminum. These panels offer excellent thermal insulation, durability, and structural strength, making them ideal for use in cold storage facilities, clean rooms, prefab buildings, and industrial sheds. PUF panels are lightweight, easy to install, and energy-efficient, helping reduce heating and cooling costs significantly.

Setting up a PUF panel…

Revolutionizing Construction: The Impact of PUF Panels on Modern Building Standa …

In the ever-evolving world of construction, materials and technologies continually push the boundaries of what is possible. Among these innovations, Polyurethane Foam (PUF) panels stand out as a game-changer, significantly impacting modern building standards. This blog explores how PUF panels are revolutionizing the construction industry by enhancing energy efficiency, improving fire safety, offering versatility, and promoting sustainability.

1. The Rise of PUF Panels

PUF panels have emerged as a transformative building material…

Pronto: A Decade of Excellence in PUF Panels, Expands to Jodhpur

May 22, 2024 - Jaipur, India - Pronto International, a distinguished leader in the PUF roofing and wall panel manufacturing industry, proudly announces its expansion to Jodhpur Rajasthan with the inauguration of an exclusive business outlet. This expansion is a testament to Pronto's decade-long legacy of quality and innovation, establishing it as a prominent brand in the industry.

A Proven Track Record

Over the past decade, Pronto International has…

PUF Sandwich Panel Market Overview: 2023-2029 Gross Revenue vs. Net Revenue Repo …

PUF Sandwich Panel report published by QYResearch reveals that COVID-19 and Russia-Ukraine War impacted the market dually in 2022. Global PUF Sandwich Panel market is projected to reach US$ 184.5 million in 2029, increasing from US$ 139 million in 2022, with the CAGR of 4.1% during the period of 2023 to 2029. Demand from Industrial and Commercial are the major drivers for the industry.

Global Leading Market Research Publisher QYResearch announces…

Pronto Launches India's Most Affordable PUF Panel - Ashvam's Heat Proof Double T …

Pronto Launches India's Most Affordable PUF Panel - Ashvam's Heat Proof Double Tin

Rajasthan, India, March 10, 2023 - Pronto, a leading building material company, has launched its revolutionary building material - Ashvam Heat Proof Double Tin. This product is a perfect replacement for the traditional tin sheet, which is highly prone to heat in summers and leakage in rain.

Ashvam Heat Proof Double Tin costs just Rs 104/SqFt, which…