Press release

The Complete ERW Pipe Manufacturing Process Explained Step-by-Step

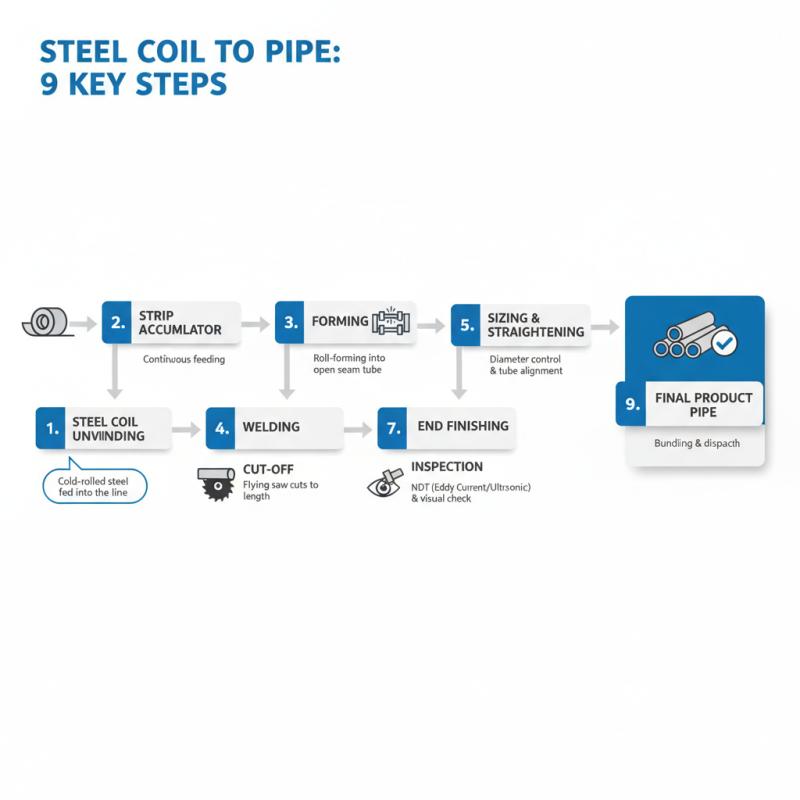

Image: https://ecdn6.globalso.com/upload/p/3937/image_other/2025-09/erw-pipe-manufacturing-process-infographic.jpgIntroduction

Electric Resistance Welded (ERW) pipe [https://www.cortecsteel.com/erw-electric-resistance-welding-pipe-product/] has become an essential part of modern industry due to its strength, uniformity of properties, and ease of production. However, how does a flat strip of steel become a high-integrity pipe with no filler metal? This guide will take you through the modern High-Frequency ERW manufacturing process and explain essential processes with key parameters, and quality-checking at each stage.

ERW Manufacturing: Key Stages and Quality Control

Stage

Step-by-Step Process

Critical Parameters / Quality Checks

1. Uncoiling & Slitting

A master steel coil is unrolled and cut by rotary knives into narrower strips of a precise width.

Strip Width Tolerance ( plus-minus 0.2mm); Edge Quality (No burrs).

2. Forming

The flat strip is passed through a series of rollers that progressively bend it into a round, open-seam tube.

OD and Roundness Control; Seam Gap Alignment.

3. Welding

A high-frequency (HF) current (100-800 kHz) is induced on the strip edges, heating them to a plastic state.

HF Power & Frequency; Welding Temperature Monitoring.

4. Forging

Squeeze rollers apply immense pressure, forging the heated edges together into a homogenous weld seam.

Squeeze Pressure; Upset Formation.

5. Seam Treatment

Internal and external weld beads (upset) are removed (scarfed) by cutting tools for a smooth surface.

Scarfing Tool Condition; Surface Finish Inspection.

6. In-line NDT

The weld seam is immediately scanned by an in-line Ultrasonic or Eddy Current testing unit.

100% Weld Seam Inspection for Defects.

7. Sizing & Straightening

The pipe passes through more rollers to achieve final, precise diameter and straightness.

Final OD Tolerance (e.g., plus-minus 0.5%); Straightness (

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Complete ERW Pipe Manufacturing Process Explained Step-by-Step here

News-ID: 4179972 • Views: …

More Releases from ABNewswire

Patio Elegance Brings Commercial-Grade Outdoor Kitchens and European Wellness De …

Patio Elegance establishes new standards for outdoor living by offering exclusively commercial-grade products built for decades of performance. The comprehensive collection spans professional kitchen islands and grills, authentic Lithuanian saunas, therapeutic cold plunges and jacuzzis, elegant gazebos, entertainment mancaves, and premium furniture all unified by European design excellence and institutional durability.

The outdoor living industry has long suffered from a quality gap, with most residential products failing to deliver the durability…

Andatel Grande Patong Phuket: Full Renovation Complete, Reopens Late March 2026

Andatel Grande Patong Phuket property: 122-room hotel across three buildings with iconic Olympic-size pool between two guest buildings, completely renovated after six-year COVID closure addressing extensive mold damage, all rooms 24 square meters with identical furniture/design.

PATONG, Phuket, Thailand - One of the best Andatel Grande Patong Phuket option in Phuket that is booked on Booking.com, Agoda, Hotels.com and more with free cancellation until 48 hours of check-in date that doesn't…

Insulin Resistance Pipeline 2025: Therapies Under Investigation, Clinical Trials …

(Las Vegas, Nevada, United States) As per DelveInsight's assessment, globally, Insulin Resistance pipeline constitutes 8+ key companies continuously working towards developing 10+ Insulin Resistance treatment therapies, analysis of Clinical Trials, Therapies, Mechanism of Action, Route of Administration, and Developments analyzes DelveInsight.

"Insulin Resistance Pipeline Insight, 2025" report by DelveInsight outlines comprehensive insights into the present clinical development scenario and growth prospects across the Insulin Resistance Market.

The Insulin Resistance Pipeline report embraces…

Caliente Brands Targets Niche Spice Market with Hickory-Smoked Beef Jerky Line F …

Caliente Brands, LLC capitalizes on growing consumer demand for authentically spicy snacks with a specialized beef jerky line that puts heat first. Using only 100% USDA Approved Beef and hickory smoking techniques, the veteran-owned company offers distinctive flavors including innovative Spicy Birria alongside traditional options, all designed to deliver the brand promise that smoky and spicy meet delicious.

Caliente Brands, LLC has strategically positioned itself to serve a niche but substantial…

More Releases for ERW

ERW Pipe Mill Round To Square Sharing - ZTZG

When people make round pipes of different specifications, the molds for the forming part of Zhongtai Pipe Technology's Erw tube mill [https://www.ztzgsteeltech.com/120x120x4-erw-pipe-mill-machinesquare-sharing-rollerszfii-b-7-product/]are all shared and can be adjusted automatically. This means that people don't have to switch molds for different pipe sizes, saving them significant time and effort. Zhongtai's advanced technology ensures that the adjustment process is seamless and precise, allowing for high efficiency and consistent quality in their production…

ERW pipe standard

Electric Resistance Welded (ERW) pipes are a widely used type of steel pipe known for their versatility, cost-effectiveness, and applicability across various industries. In this comprehensive guide, we will explore the characteristics, manufacturing processes, standards, and applications of ERW pipes, shedding light on their significance in construction, infrastructure, oil and gas, and other sectors.

1.Introduction to ERW Pipes

ERW pipes are steel pipes manufactured through the process of electric resistance welding, which…

Explanation of Common Defects in ERW Welded Pipes

Explanation of common defects in ERW welded pipes:

Undercut

Undercut is a groove that appears along the centerline of the weld in the transition area between the edge of the weld and the pipe body. Undercut occurs when welding speed, current, voltage and other conditions are not properly matched.

lap welding

The upper and lower edges of the steel plate are misaligned and butted, resulting in uneven welds, which become pipe seam misalignment or…

The Differences Between ERW and Seamless Steel Pipes

The Differences Between ERW pipes(https://www.eastern-steels.com/products/erw-steel-pipe.html) and Seamless Steel Pipes(https://www.eastern-steels.com/products/carbon-steel-seamless-line-pipe.html)

Steel pipes are used in a wide range of applications, from oil and gas pipelines to structural steel and more. Two of the most common types of steel pipes are ERW pipes and seamless pipes. While both types of pipes are made from high-quality steel, there are some significant differences between the two. In this article, we will explore the differences between…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Performance Comparison of ERW and Spiral Steel Pipe

Performance comparison of carbon ERW steel pipe and spiral steel pipe:

1. Overview

The welding of ERW steel pipe is the skin effect and proximity effect of high-frequency current. The process of using high-frequency current and induced high-frequency current (rising at the end of the 20th century) resistance to heat and melt the edge of the tube blank, and apply squeezing force to weld together process.

The welding of SSAW steel pipe is…