Press release

Food Color Manufacturing Plant Setup Cost 2025: Machinery Requirements and Project Economics

Food color is a substance used to enhance or restore the color of food and beverages, making them more visually appealing and consistent in appearance. It can be derived from natural sources like fruits, vegetables, and spices, or synthesized as artificial colorants. Food colors are widely used in confectionery, beverages, bakery products, dairy, snacks, and processed foods. They not only improve aesthetic appeal but also help in brand recognition and consumer preference. Common forms include liquid, powder, and gel, and their usage is regulated to ensure safety and compliance with food standards.Setting up a food color production plant involves sourcing natural or synthetic raw materials, installing mixing, extraction, drying, and packaging machinery, and establishing a facility that meets hygiene and regulatory standards. A small-scale plant requires investment in equipment, quality control systems, trained staff, and licenses, with cost varying by production capacity and product range.

IMARC Group's report, titled "Food Color Manufacturing Plant Setup Cost 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a Food Color manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Food Color Industry Outlook 2025:

In 2025, the food color industry is experiencing a strong shift toward natural, plant-based alternatives, driven by increasing consumer demand for clean-label and health-conscious products. Manufacturers are moving away from synthetic dyes due to growing health concerns, stricter regulations, and brand commitments to transparency. Natural colorants derived from fruits, vegetables, algae, and spices are gaining popularity across food and beverage applications, supported by advancements in formulation, stability, and extraction technologies. Regulatory developments and public pressure are encouraging companies to reformulate products using safer, more sustainable ingredients. With innovation and consumer trends aligning, the food color industry is expected to see continued growth, particularly in natural and organic segments.

Request for Sample Report: https://www.imarcgroup.com/food-color-manufacturing-plant-project-report/requestsample

Key Insights for Food Color Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy Now: https://www.imarcgroup.com/checkout?id=22469&method=1911

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Food Color Plant:

• Raw Materials: Includes natural sources like fruits, vegetables, algae, spices, or synthetic chemicals, depending on the type of food color being produced.

• Processing Machinery: Equipment for extraction, filtration, blending, drying (e.g., spray or freeze dryers), and standardization-essential for transforming raw materials into usable colorants.

• Land and Building: Costs associated with acquiring land, constructing production units, storage facilities, laboratories, and administrative areas.

• Utilities and Infrastructure: Expenditure on power, water, steam, HVAC systems, and effluent treatment plants necessary for smooth and compliant operations.

• Quality Control and R&D: Laboratories and testing equipment for ensuring color stability, purity, and compliance with food safety standards.

• Packaging and Storage: Investment in moisture-proof, light-protective, and food-safe packaging materials and systems, plus warehouse infrastructure.

• Labor and Staffing: Costs for skilled technicians, food chemists, operators, quality control personnel, and administrative staff.

• Licensing and Compliance: Expenses for obtaining food safety certifications, regulatory approvals, and adherence to national and international standards.

• Automation and Control Systems: Optional costs for digital systems, sensors, and automation for improved consistency and efficiency.

• Maintenance and Spare Parts: Ongoing investment for machinery upkeep and availability of spare parts to prevent downtime.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=22469&flag=C

Economic Trends Influencing Food Color Plant Setup Costs 2025:

• Raw Material Price Volatility: Natural colorants depend on crops like fruits, vegetables, algae, and spices whose prices fluctuate sharply due to seasonal availability and climate factors. Synthetic dye feedstocks are cheaper but under regulatory scrutiny.

• Regulatory Shifts: Bans on synthetic dyes compel manufacturers to use natural alternatives, raising formulation and compliance costs.

• Higher Raw Material Requirements: Natural pigments often require larger input quantities to match color intensity, increasing production costs and affecting economies of scale.

• Shorter Shelf Life & Stability Demands: Natural colors are generally less stable to heat, light, and pH-necessitating advanced extraction, stabilization, encapsulation systems that increase R&D and equipment costs.

• Inflation & Utility Costs: Rising energy, water, steam, and raw material costs add pressure on operational budgets and plant overhead.

• Supply Chain Uncertainty & Crop Risks: Agricultural volatility-driven by weather shifts and logistics delays-impacts raw material availability and may force premium pricing or inventory buffers.

• Technological Investment Requirements: To meet demand for clean-label, vibrant natural colors, plants must invest in advanced extraction and stabilization technologies, raising capital expenditure.

• Innovator Premiums & Scale Constraints: Leading clean-label players and biotech innovators invest heavily in fermentation-based extraction or customized solutions, commanding higher prices per kg.

Challenges and Considerations for Investors in Food Color Plant Projects:

• Regulatory Compliance: Strict food safety standards and shifting regulations-especially bans on synthetic dyes-require constant monitoring and adjustments in formulations and labeling.

• Raw Material Dependence: Natural food color production relies on seasonal crops and botanical sources, which are vulnerable to climate change, price fluctuations, and supply chain disruptions.

• Higher Production Costs: Natural colorants often require larger quantities of raw material, advanced processing techniques, and stabilization systems, leading to higher capital and operational expenditure.

• Technology Investment: Ensuring product stability, intensity, and shelf life demands specialized equipment for extraction, encapsulation, and quality control-raising initial setup costs.

• Shorter Shelf Life: Many natural colors degrade faster under heat, light, or pH variations, creating challenges in storage, distribution, and product formulation.

• Market Competition: Established multinational players dominate the natural color market, making it difficult for new entrants to differentiate without innovation or niche targeting.

• Consumer Expectations: Growing demand for clean-label products also brings expectations for consistent color, transparency, and traceability-putting pressure on sourcing and branding.

• Skilled Workforce: The need for food technologists, quality control experts, and R&D professionals may be difficult to fulfill in certain regions.

• Product Customization Needs: Food manufacturers often require tailored color solutions to match specific applications, increasing formulation complexity and development time.

• Return on Investment Timeline: Given high setup and R&D costs, especially in natural food colors, breakeven and profitability may take longer without strong distribution and brand partnerships.

Conclusion:

The food color industry in 2025 offers promising opportunities driven by the growing global shift toward natural, clean-label ingredients. Setting up a food color manufacturing plant involves strategic investment in specialized machinery, raw materials, and compliance systems tailored to evolving consumer and regulatory demands. While the industry presents significant growth potential, particularly in the natural segment, investors must navigate challenges such as raw material variability, rising costs, and intense market competition. With the right combination of innovation, quality control, and market alignment, food color production can become a profitable and sustainable venture in the modern food landscape.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Food Color Manufacturing Plant Setup Cost 2025: Machinery Requirements and Project Economics here

News-ID: 4133841 • Views: …

More Releases from IMARC Group

Tidal Energy Plant DPR - 2026, Feasibility Report, CapEx/OpEx & ROI Insights

Setting up a tidal energy plant positions investors in one of the most strategically significant and future-ready segments of the global renewable energy landscape, backed by sustained growth driven by the worldwide shift toward clean and predictable power generation, decarbonization commitments under international climate frameworks, rising electricity demand in coastal economies, and the growing deployment of advanced marine energy technologies. As governments worldwide accelerate offshore energy programs, mandate renewable capacity…

Mobile Accessories Manufacturing Plant DPR 2026: Investment Cost, Market Growth …

Setting up a mobile accessories manufacturing plant positions investors at the center of one of the most dynamic and consistently high-growth consumer electronics segments - driven by rapid global smartphone penetration reaching 4.69 billion users worldwide in 2025 with approximately 440 million new users added between 2024 and 2025 alone, frequent device replacement cycles generating recurring accessory demand at every upgrade event, protocol and regulation-driven product refresh cycles from mandatory…

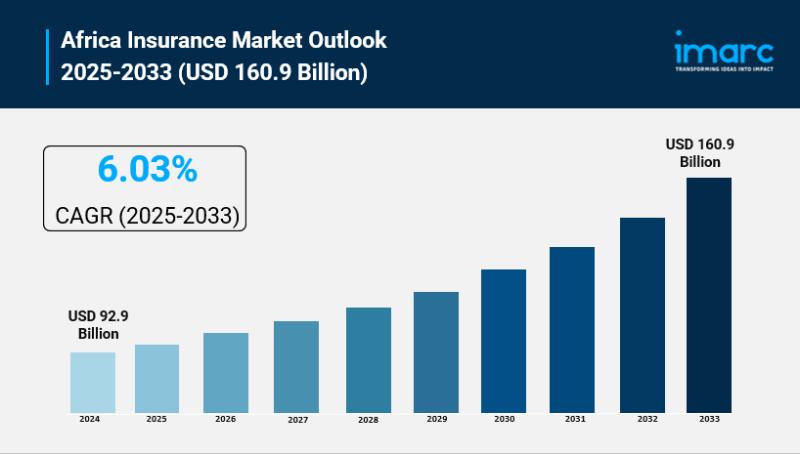

Africa Insurance Market Size to Hit USD 160.9 Billion by 2033 | With a 6.03% CAG …

Africa Insurance Market Overview

Market Size in 2024: USD 92.9 Billion

Market Size in 2033: USD 160.9 Billion

Market Growth Rate 2025-2033: 6.03%

According to IMARC Group's latest research publication, "Africa Insurance Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Africa insurance market size was valued at USD 92.9 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 160.9 Billion by 2033, exhibiting a CAGR of 6.03%…

Womenswear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/Op …

Setting up a womenswear manufacturing plant positions investors in one of the largest and most dynamic segments of the global apparel industry and fashion retail value chain, backed by sustained growth driven by rising female workforce participation, increasing fashion consciousness, growth of fast fashion and e-commerce platforms, and expanding disposable incomes in emerging economies. As global apparel consumption accelerates, fast fashion brands deepen their market penetration, and online retail platforms…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…