Press release

Caprolactam Production Cost Analysis 2025: Feasibility Study and Profit Margins

Introduction:Caprolactam is a cyclic amide with the chemical formula (CH2)5CONH, primarily used as a monomer in the production of Nylon 6. It is a colorless, crystalline organic compound that serves as the foundational building block for polyamide plastics and fibers. Nylon 6, derived from caprolactam, is widely utilized in textiles (carpets, apparel), engineering plastics (automotive parts, electrical components), and films due to its excellent strength, elasticity, and abrasion resistance.

Setting up a Caprolactam production plant typically involves complex chemical processes, most commonly the cyclohexanone oxime method. This involves several stages: converting cyclohexane to cyclohexanol, then to cyclohexanone, followed by oximation to produce cyclohexanone oxime. Finally, the Beckmann rearrangement converts the oxime to caprolactam. This process requires significant infrastructure for handling various chemicals, including highly corrosive sulfuric acid, and sophisticated environmental controls for managing by-products like ammonium sulfate.

IMARC Group's report, titled "Caprolactam Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a caprolactam production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/caprolactam-manufacturing-plant-project-report/requestsample

Caprolactam Industry Outlook 2025

The Caprolactam industry in 2025 is driven by the robust and continuous demand for Nylon 6, its primary derivative. This demand stems from the expanding automotive sector's need for lightweight, fuel-efficient parts and the flourishing textile industry for fibers and industrial yarns. India's rapid urbanization and infrastructure development also contribute, increasing the use of engineering plastics. While global oversupply has been a concern, increasing domestic production in key regions like Asia-Pacific aims to meet growing internal consumption, alongside a rising focus on sustainable production methods and bio-based caprolactam.

Key Insights for Caprolactam Production Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7663&flag=C

Key Cost Components of Setting Up a Caprolactam Plant

• Process Equipment: Major investment in complex reactors, separation units, heat exchangers, distillation columns, and specialized machinery for multiple chemical stages.

• Raw Material Storage: Extensive infrastructure for storing bulk quantities of cyclohexane, ammonia, sulfuric acid, and other intermediates, often requiring specialized and hazardous material handling.

• Utilities: High consumption of electricity, steam, and cooling water, necessitating robust utility generation and distribution systems.

• Civil Works & Buildings: Construction of multiple process units, control rooms, laboratories, warehouses, and administrative blocks.

• Environmental & Safety Systems: Significant expenditure on advanced effluent treatment, air pollution control (especially for sulfur dioxide and ammonia), and comprehensive safety protocols due to hazardous chemicals.

• Catalysts & Chemicals: Initial fill and ongoing replacement costs for various catalysts and process chemicals crucial for the reactions.

• Technology Licensing & Engineering: Costs for intellectual property, detailed engineering design, and project management expertise.

• By-product Handling: Facilities for processing and storing ammonium sulfate, a major by-product, for sale or disposal.

Economic Trends Influencing Caprolactam Plant Setup Costs 2025

• Raw Material Price Volatility: Prices of key feedstocks like cyclohexane, phenol, and ammonia are highly susceptible to global crude oil prices, energy costs, and regional supply/demand imbalances.

• Energy Costs: Caprolactam production is energy-intensive. Fluctuating natural gas and electricity prices, particularly in a global context, directly impact operating expenses and overall project viability.

• Global Supply-Demand Dynamics: While Nylon 6 demand is growing, any global oversupply of caprolactam or weak downstream demand for Nylon 6 can put pressure on prices and thus on investment returns.

• Technological Advancements: Investments in new, more efficient, and potentially sustainable production methods might have higher initial capital costs but could offer long-term operational savings and market advantages.

• Environmental Regulations: Increasingly stringent environmental norms, especially regarding emissions of hazardous chemicals and waste treatment, necessitate significant investment in advanced pollution control systems.

Challenges and Considerations for Investors

• Raw Material Price Volatility: Heavy reliance on crude oil derivatives like benzene and cyclohexane makes production costs highly susceptible to global energy market fluctuations.

• Global Oversupply: The market has experienced periods of oversupply, especially from Asia-Pacific, leading to depressed prices and impacting profit margins.

• Intense Competition: Numerous established global and regional players create a highly competitive landscape, necessitating efficient operations and strong market positioning.

• Environmental Regulations: Stringent environmental norms, particularly concerning emissions and waste from sulfuric acid and ammonia by-products, add significant compliance costs.

• By-product Management: Effectively marketing or disposing of ammonium sulfate, a major by-product, is crucial for economic viability.

• Technological Shifts: While slower than other sectors, the emergence of bio-based caprolactam and other sustainable alternatives could pose long-term competitive threats.

• Downstream Demand Fluctuations: Demand for Caprolactam is directly tied to the Nylon 6 industry (textiles, automotive, engineering plastics), making it vulnerable to downturns in these sectors.

Buy Now: https://www.imarcgroup.com/checkout?id=7663&method=1911

Conclusion

This report aims to serve as a practical guide for entrepreneurs, investors, and industrial planners exploring opportunities in caprolactam production. By understanding the cost structure, market dynamics, and operational challenges, stakeholders can make informed decisions and devise sustainable strategies for entry and expansion in the sector.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Caprolactam Production Cost Analysis 2025: Feasibility Study and Profit Margins here

News-ID: 4133517 • Views: …

More Releases from IMARC Services Private Limited

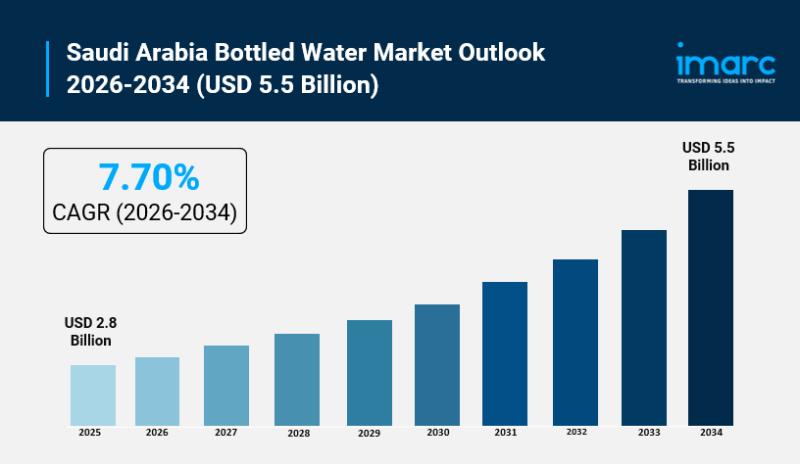

Saudi Arabia Bottled Water Market Set to Surge USD 5.5 Billion by 2034, Rising a …

Saudi Arabia Bottled Water Market Overview

Market Size in 2025: USD 2.8 Billion

Market Forecast in 2034: USD 5.5 Billion

Market Growth Rate 2026-2034: 7.70%

According to IMARC Group's latest research publication, "Saudi Arabia Bottled Water Market Size, Share, Trends and Forecast by Type, Distribution Channel, Packaging Size, and Region, 2026-2034", the Saudi Arabia bottled water market size was valued at USD 2.8 Billion in 2025. Looking forward, IMARC Group estimates the market to…

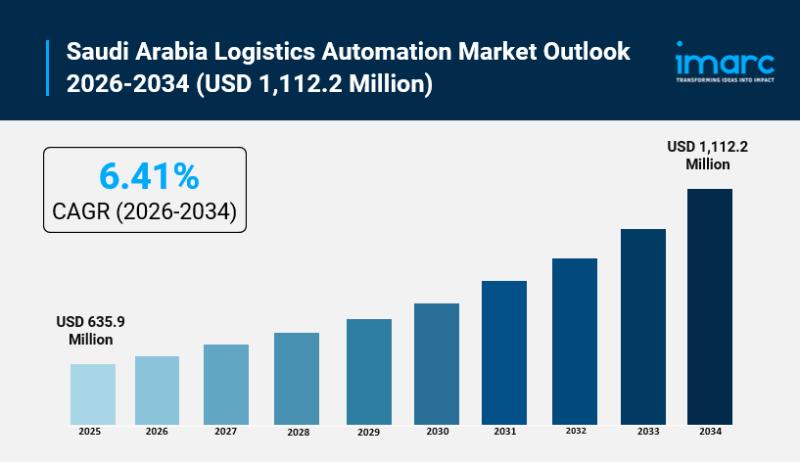

Saudi Arabia Logistics Automation Market Size to Worth USD 1,112.2 Million by 20 …

Saudi Arabia Logistics Automation Market Overview

Market Size in 2025: USD 635.9 Million

Market Forecast in 2034: USD 1,112.2 Million

Market Growth Rate 2026-2034: 6.41%

According to IMARC Group's latest research publication, "Saudi Arabia Logistics Automation Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", the Saudi Arabia logistics automation market size reached USD 635.9 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,112.2 Million by 2034, exhibiting…

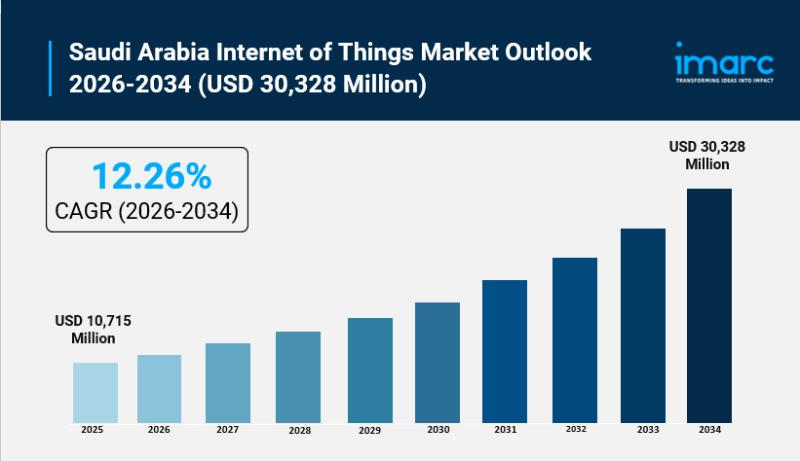

Saudi Arabia Internet of Things Market Set to Reach USD 30,328 Million by 2034 A …

Saudi Arabia Internet of Things Market Overview

Market Size in 2025: USD 10,715 Million

Market Forecast in 2034: USD 30,328 Million

Market Growth Rate 2026-2034: 12.26%

According to IMARC Group's latest research publication, "Saudi Arabia Internet of Things Market Size, Share, Trends and Forecast by Component, Application, Vertical, and Region, 2026-2034", The Saudi Arabia internet of things market size was valued at USD 10,715 Million in 2025 and is projected to reach USD 30,328…

Saudi Arabia Duty-Free and Travel Retail Market Projected to Reach USD 726.1 Mil …

Saudi Arabia Duty-Free and Travel Retail Market Overview

Market Size in 2025: USD 417.7 Million

Market Forecast in 2034: USD 726.1 Million

Market Growth Rate 2026-2034: 6.34%

According to IMARC Group's latest research publication, "Saudi Arabia Duty-Free and Travel Retail Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2026-2034", the Saudi Arabia duty-free and travel retail market size reached USD 417.7 Million in 2025. Looking forward, IMARC Group expects…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…