Press release

Yarn Lubricants Market to Reach USD 5.7 Billion by 2034, Driven by Textile Industry Growth

The global Yarn Lubricants Market was valued at USD 1.5 billion in 2023 and is projected to reach USD 5.7 billion by 2034, growing at a robust CAGR of 12.9% from 2024 to 2034. This growth is driven by the rising demand for high-performance textile processing, increasing textile production across emerging economies, and the need for enhanced fiber quality and machinery efficiency in spinning and weaving operations.Rise in demand for biodegradable lubricants is driving the yarn lubricants market dynamics. The textile sector is emphasizing sustainable practices to reduce the environmental impact of textile manufacturing. As a result, innovations in yarn lubricant technology have led to the development of eco-friendly solutions that are biodegradable and can improve efficiency.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=74471

Yarn lubricants are specialized chemical formulations applied to yarns during manufacturing processes such as spinning, weaving, and knitting. Their primary function is to reduce friction between fibers themselves and between fibers and machinery, thereby preventing breakage, minimizing wear and tear on equipment, and improving overall production speed and yarn quality. These lubricants also impart desired properties to the yarn, such as softness, antistatic characteristics, and improved winding performance.

Market Segmentation

The yarn lubricants market can be segmented based on various factors, providing a comprehensive view of its dynamics:

By Service Type: While not explicitly categorized as "service types," the application of yarn lubricants is integral to various textile manufacturing processes. Key areas include:

Spinning: Lubricants are crucial here for smooth fiber processing and yarn formation.

Weaving: Essential for reducing friction and preventing damage during the interlacing of yarns on looms.

Knitting: Improves the smooth flow of yarn through knitting machines, enhancing fabric quality.

Textile Finishing: Contributes to the final look, feel, durability, and wear resistance of textiles.

By Sourcing Type:

Natural Lubricants: Derived from natural sources.

Synthetic Lubricants: Chemically synthesized for specific performance characteristics.

Biodegradable Lubricants: A growing segment driven by environmental concerns, offering eco-friendly alternatives.

By Application: This segmentation often refers to the type of yarn or fiber being processed:

Polyester: Expected to remain the dominant segment due to its widespread use, cost-effectiveness, and durability.

Nylon

Acrylic

Cotton

Wool

Blends: Increasing popularity of blended yarns (combining natural and synthetic fibers) for performance wear, home textiles, and fashion.

By Industry Vertical (End-use):

Apparel: The largest consumer, driven by continuous demand for clothing.

Home Textiles: Includes applications in bedding, upholstery, and decorative fabrics.

Technical Textiles: High-performance textiles used in automotive, medical, industrial, and construction sectors.

By Formulation Type:

Water-Soluble Lubricants

Oil-Based Lubricants

Emulsion-Based Lubricants

Coning Oil: A significant segment, particularly projected to hold the largest share due to its excellent lubricity and ability to reduce friction, preventing yarn breakage and increasing operational speed.

Spin Finish: Dominant in synthetic fiber processing.

Knitting Oil

Grease

Regional Analysis

Geographically, the yarn lubricants market exhibits varied growth patterns:

Asia-Pacific: This region is anticipated to be the largest and fastest-growing market. Rapid industrialization and significant textile manufacturing activities, particularly in countries like China, India, Bangladesh, and Vietnam, are driving robust demand. Investments in high-speed yarn production and the growing demand for synthetic and blended yarns contribute significantly to the region's market growth.

North America: Expected to hold a substantial share, supported by a mature textile industry and a strong focus on performance-driven and environmentally sustainable solutions.

Europe: Benefits from a well-established textile industry with a strong emphasis on quality and environmental compliance. The increasing shift toward eco-friendly and biodegradable lubricants, especially in Germany, Italy, and France, is fueling market expansion.

Latin America, Middle East, and Africa: These regions contribute to the growing global demand, with Latin America witnessing gradual adoption and improving economic conditions, and the Middle East and Africa showing steady growth.

Visit our report to gain in-depth insights - https://www.transparencymarketresearch.com/yarn-lubricants-market.html

Market Drivers and Challenges

Market Drivers:

Increasing Demand for Textiles and Apparel: Global population growth, urbanization, and changing fashion preferences are continuously driving the demand for textiles, directly impacting the need for yarn lubricants.

Technological Advancements in Textile Manufacturing: The adoption of high-speed spinning, weaving, and knitting machines, along with increasing automation in textile production, necessitates advanced lubricants that can withstand extreme conditions and enhance efficiency.

Growing Focus on Yarn Quality and Production Efficiency: Manufacturers are constantly seeking ways to improve yarn strength, reduce breakage, and achieve uniform texture, all of which are facilitated by effective lubrication.

Rising Preference for Sustainable and Eco-Friendly Lubricants: Environmental concerns and stricter regulations are propelling the demand for biodegradable, non-toxic, and low-emission yarn lubricants.

Expansion of Technical Textiles: The increasing use of high-performance yarns in automotive, medical, and industrial applications contributes to market growth.

Market Challenges:

Volatile Raw Material Prices: Fluctuations in the cost of base oils and additives can impact production costs and pricing stability for lubricant manufacturers.

Stringent Environmental Regulations: The need to develop sustainable lubricants that meet rigorous performance criteria while adhering to environmental norms increases research and development complexity and expenditure.

Competition from Alternative Technologies: While not a direct threat, advancements in fiber technology might influence lubricant requirements in the long term.

Lack of Uniform Regulations: In some regions, the absence of clear guidelines for yarn lubricants can hinder market growth and adoption of sustainable solutions.

Market Trends

Shift Towards Biodegradable and Bio-based Lubricants: This is a major trend, driven by environmental consciousness and regulatory pressures. Companies are investing in R&D to develop high-performance, sustainable alternatives.

Development of Specialized Lubricants for High-Speed Machinery: The increasing speed of textile machinery demands lubricants that can provide superior performance under intense operating conditions, reducing friction and heat generation.

Focus on Energy Efficiency: Lubricants that contribute to reduced energy consumption in textile manufacturing processes are gaining traction.

Integration of Smart Lubricants: Future trends might include lubricants with embedded sensors or compatibility with digital twin technologies for predictive maintenance and real-time monitoring.

Customized Formulations: Demand for tailored lubricant solutions that address specific yarn types, machinery, and production conditions.

Future Outlook

The yarn lubricants market is expected to continue its upward trajectory, driven by the expanding global textile industry and the increasing emphasis on efficiency, quality, and sustainability. The focus on developing environmentally friendly and high-performance lubricants will shape the market's future.

Emerging economies, particularly in Asia-Pacific, will remain key growth drivers due to their expanding manufacturing bases. Innovation in formulation and application technologies, along with strategic collaborations, will be crucial for market players to thrive.

Key Market Study Points

Impact of sustainable practices on market dynamics: How will the shift to eco-friendly solutions reshape the competitive landscape?

Technological advancements in yarn processing: How do innovations in machinery influence lubricant requirements and development?

Regional variations in textile production and consumption: Understanding diverse market needs and regulatory environments.

Pricing strategies in response to raw material volatility: How do manufacturers manage cost fluctuations?

The evolving role of digital technologies in lubricant management: From predictive maintenance to supply chain optimization.

Competitive Landscape

The global yarn lubricants market is characterized by the presence of several key players, including:

Total S.A.

Clearco Products

Achitex Minerva

Rudolf GmbH

Siam Pro Dyechem Group

Bozzetto Group

Klueber Lubrication München SE & Co. KG

Sar Lubricants

Schill & Seilacher

Zhejiang Communication

Takemoto Oil & Fat Co., Ltd.

Resil Chemicals Pvt. Ltd.

Graf Chemicals

Vickers Oil

BASF SE

DuPont de Nemours Inc.

Huntsman International LLC

Wacker Chemie AG

Clariant AG

Solvay S.A.

These companies are actively engaged in research and development, focusing on product innovation, expanding manufacturing facilities, and forging strategic partnerships to gain a competitive edge. The competitive environment is also shaped by a growing emphasis on sustainable product offerings and compliance with environmental regulations.

Recent Developments

Rudolf GmbH opened a new site in Nantong, China (April 2023): This move aims to boost their local and global competitiveness, underscoring their commitment to innovation in the textile and related industries.

Increased focus on biodegradable and non-toxic formulations: Manufacturers are continually introducing new lubricant compositions that break down easily and conform to environmental regulations, while maintaining fiber strength and enhancing productivity.

Development of specialized coning oils: Continued advancements in coning oils aim to further reduce friction, minimize yarn breakage, and increase operational speed in high-volume textile manufacturing.

Innovation in lubricants for synthetic fibers (especially polyester): Given polyester's dominance, R&D efforts are concentrated on developing lubricants that optimize its processing and enhance its properties for diverse applications.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=74471<ype=S

The yarn lubricants market is dynamic and integral to the advancement of the textile industry. As the world continues to demand high-quality, sustainable, and efficiently produced textiles, the role of innovative yarn lubricants will only become more critical.

Explore Latest Research Reports by Transparency Market Research:

Lipophilic Dyes Market - https://www.transparencymarketresearch.com/lipophilic-dyes-market.html

Sustainable Phosphorus Market - https://www.transparencymarketresearch.com/sustainable-phosphorus-market.html

Polar Polymers Market - https://www.transparencymarketresearch.com/polar-polymers-market.html

RFCC Catalyst Market - https://www.transparencymarketresearch.com/rfcc-catalyst-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Want to know more? Get in touch now. -https://www.transparencymarketresearch.com/contact-us.html

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Yarn Lubricants Market to Reach USD 5.7 Billion by 2034, Driven by Textile Industry Growth here

News-ID: 4120812 • Views: …

More Releases from transparencymarketresearch

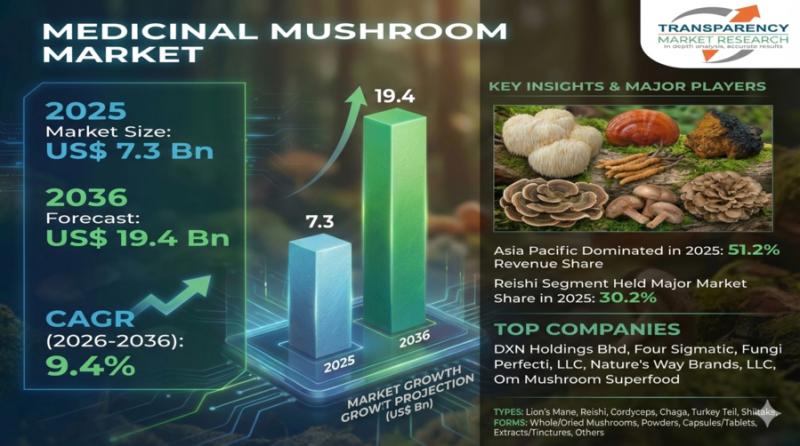

Medicinal Mushrooms Market to Reach USD 19.4 Bn by 2036, Growing at 9.4% CAGR

The global Medicinal Mushrooms Market size was valued at US$ 7.3 Bn in 2025 and is projected to reach US$ 19.4 Bn by 2036, expanding at a CAGR of 9.4% from 2026 to 2036. The global Medicinal Mushrooms industry is expanding due to increased awareness of natural health solutions, rising chronic disease prevalence, wider acceptance of traditional medicine, growing use in supplements and pharmaceuticals, and enhanced accessibility through e-Commerce and…

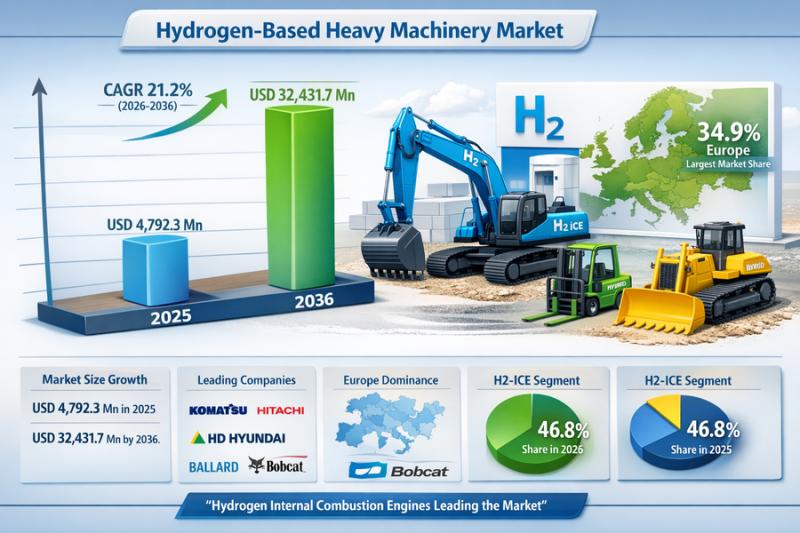

Hydrogen-Based Heavy Machinery Market Set to Reach USD 32.4 Billion by 2036 | TM …

The hydrogen-based heavy machinery market was valued at USD 4,792.3 million in 2025 and is projected to surge to USD 32,431.7 million by 2036. Driven by rapid adoption of clean energy technologies and stringent emission regulations, the industry is expected to grow at a robust CAGR of 21.2% during the forecast period from 2026 to 2036.

The hydrogen-powered heavy machinery market is gaining recognition and is slowly but surely emerging. Referring…

Online Dermatology Consultation Market to Reach USD 9.2 Billion by 2035, Growing …

The online dermatology consultation market was valued at USD 2.8 billion in 2024 and is projected to reach USD 9.2 billion by 2035. Driven by the rising adoption of telemedicine, increasing prevalence of skin disorders, and growing demand for convenient, remote healthcare services, the industry is expected to expand at a CAGR of 11.4% from 2025 to 2035, reflecting strong long-term growth potential.

Technological advancements in telemedicine and artificial intelligence is…

Human Milk Bank Market to Reach USD 843.1 Million by 2035, Growing at a CAGR of …

The global human milk bank market was valued at USD 422.7 million in 2024 and is projected to grow steadily, reaching USD 843.1 million by 2035. This growth reflects the rising awareness of the benefits of donor human milk, the increasing prevalence of preterm births, and the expanding neonatal care infrastructure worldwide. The industry is expected to expand at a CAGR of 6.4% from 2025 to 2035, supported by favourable…

More Releases for Lubricants

Indonesia Lubricant Market Expected to Surpass USD 4.36 Billion Mark by 2031 | M …

USA, New Jersey: Verified Market Research reports that the global IIndonesia Lubricant Market size was valued at USD 2.46 Billion in 2024 and is projected to reach USD 4.36 Billion by 2032, growing at a CAGR of 7.4% from 2025 to 2032. This steady growth is driven by increasing environmental regulations, rising awareness of pollution control, and expanding applications in industries such as manufacturing, energy, and healthcare.

Indonesia Lubricant Market -…

India Industrial Lubricants Market Drivers: Apar Industries, Valvoline Cummins, …

The India industrial lubricants market is poised for significant expansion, with its valuation anticipated to climb from an estimated USD 59.4 billion in 2025 to a remarkable USD 86.8 billion by 2035, exhibiting a Compound Annual Growth Rate (CAGR) of 3.8%. This impressive trajectory is fundamentally driven by increased domestic manufacturing, substantial infrastructure investment, and rising awareness of predictive maintenance practices across key industries such as steel, cement, textiles, and…

Biodegradable Lubricants Will Support Demand for Agricultural Lubricants

The material known as a lubricant is used to lessen friction or abrasion between two surfaces that are in touch with one another. It is accessible in solid, liquid, and gaseous states and aids in the removal of heat and the transition of power.

Semisolid versions of them can also be discovered. Grease is one of the most typical types of lubricants in a semisolid form. To boost productivity, lubricants are…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricants are essential for modern life. Thanks to the sophisticated oil and grease integration, car engines and transmissions run smoothly.

Lubricants are great fluids. Irrespective of weather conditions, engine oil must operate reliably in the temperature range of 40°C to 250°C or higher (piston ring upper temperature). It must also withstand pressures of 105 to 109 Pascals and contaminants such as metal particles and soot.

Lubricants perform the main functions of…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricants are essential in modern life. Car machines and gearboxes run smoothly through the integration of advanced oils and fats. Lubricants are remarkable liquids. Regardless of the weather conditions, the engine oil must operate reliably at temperatures of 40 ° C to above 250 ° C - the temperature near the upper piston ring. It also has to deal with presses between 105 and 109 Pascacakes as well as contaminants,…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricating oils are essential to modern life. Automotive engines and gearboxes run smoothly due to the sophisticated oil and grease integration. Lubricating oil is an amazing fluid. Regardless of weather conditions, engine oil should operate stably at temperatures in the range of 250 ° C and above (the temperature near the upper piston ring) at 40 ° C. It also deals with pressures between 105 and 109 Pascals, as well…