Press release

Metal Injection Molding Market To Hit USD 9.5 Billion by 2033 | CAGR of 8.21%

IMARC Group's latest research report, titled "Metal Injection Molding Market Report by Material Type (Stainless Steel, Low Alloy Steel, Soft Magnetic Material, and Others), End Use Industry (Electrical and Electronics, Automotive, Medical and Orthodontics, Consumer Products, Firearms and Defense, and Others), and Region 2025-2033," offers a comprehensive analysis of the metal injection molding market. The report also includes competitor and regional analysis, along with a breakdown of segments within the industry. the global metal injection molding market size was valued at USD 4.6 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 9.5 Billion by 2033, exhibiting a CAGR of 8.21% from 2025-2033. In 2024, United States accounted for 83.38% of the metal injection modeling market share in North America. The market is growing rapidly due to the increasing requirement for miniaturized components in electronics and healthcare sectors, rising demand for lightweight parts in the automotive industry, expanding need in medical and dental applications, heightened awareness about the technique's cost-efficiency in mass production, and rapid advancements in material science.Get free Sample Copy of Report at - https://www.imarcgroup.com/metal-injection-molding-market/requestsample

Technological Advancements and Material Innovation:

The metal injection molding (MIM) market is experiencing a significant surge in technological advancements and material innovation, fundamentally reshaping its competitive landscape and growth trajectory. MIM technology integrates the versatility of plastic injection molding with the strength and performance of powdered metallurgy, enabling the mass production of complex, high-precision metal components previously unattainable through conventional methods. Recent breakthroughs in feedstock formulation, such as the use of advanced alloys and suspension-based binders, have expanded the range of metals that can be processed-including stainless steel, cobalt alloys, nickel alloys, and even superalloys tailored for high-temperature applications. These innovations have resulted in components with enhanced mechanical properties, superior corrosion resistance, and improved biocompatibility, opening new avenues in demanding sectors like automotive, aerospace, consumer electronics, and medical devices.

The integration of artificial intelligence and data-driven process optimization is further elevating production efficiency, reducing cycle times, and minimizing defects, thereby lowering costs and waste. The adoption of sustainable and bio-based polymers as binders is also gaining traction, supporting environmental goals and regulatory compliance. As manufacturers increasingly seek solutions that combine design flexibility, scalability, and sustainability, the ongoing evolution of MIM technology and materials is reinforcing its position as a preferred choice for next-generation component manufacturing, fueling robust market growth and global adoption.

Expanding Application Scope Across Key End-Use Industries:

The versatility and cost-effectiveness of metal injection molding are driving its rapid adoption across a diverse array of end-use industries, each with unique requirements for high-performance, miniaturized, and intricately shaped components. In the automotive sector, the push for lightweighting and fuel efficiency is propelling the use of MIM for the production of complex engine parts, transmission systems, and safety mechanisms, as well as specialized components for electric vehicles that demand both reduced weight and high strength. The healthcare industry is leveraging MIM's precision and biocompatibility to manufacture surgical instruments, dental implants, and orthopedic devices with intricate geometries and tight tolerances, all while minimizing material waste and production costs.

Consumer electronics remain a dominant market segment, with MIM enabling the fabrication of miniature, high-strength parts for smartphones, wearables, and advanced camera systems. Aerospace and defense sectors are also embracing MIM for its ability to deliver robust, lightweight, and reliable components that meet stringent industry standards. The method's scalability and repeatability make it ideal for mass production, supporting industries' needs for high-volume, cost-efficient manufacturing. As global industrialization accelerates, particularly in Asia-Pacific and emerging economies, the demand for MIM solutions is set to expand further, driven by the need for innovative components that enhance product functionality, durability, and performance.

Sustainability, Cost Efficiency, and Global Manufacturing Shifts:

Sustainability and cost efficiency are becoming central pillars of the metal injection molding market's growth, as industries worldwide seek to optimize resource utilization and minimize environmental impact. MIM's inherent advantage lies in its ability to significantly reduce material wastage compared to traditional metalworking processes, as nearly all raw material is converted into finished product. This efficiency not only lowers production costs but also supports corporate sustainability initiatives and compliance with increasingly stringent environmental regulations.

The cost-effectiveness of MIM is further amplified by its minimal need for secondary finishing operations, reduced labor requirements, and streamlined inventory management, making it a highly attractive option for manufacturers aiming to maximize profitability and operational agility. The global manufacturing landscape is witnessing a shift, with Asia-Pacific emerging as a dominant force due to its robust industrial base, cost-competitive manufacturing, and growing demand for high-performance metal components. Meanwhile, North America and Europe are strengthening their positions through technological innovation, capacity expansion, and a focus on advanced applications in automotive, aerospace, and healthcare. The convergence of sustainability, cost efficiency, and strategic regional investments is shaping the future of the MIM market, ensuring its continued expansion and relevance in a rapidly evolving industrial ecosystem.

Leading Key Players Operating in the Metal Injection Molding Industry:

• Amphenol Corporation

• ARC Group Worldwide Inc

• ATW Companies Inc

• CMG Technologies

• CN Innovations Ltd.

• Dean Group International Ltd

• Ernst Reiner GmbH & Co. KG

• Metal Powder Products LLC

• Parmaco Metal Injection Molding AG

• Sintex a/s

• Smith Metal Products

• Tanfel Metal

Metal Injection Molding Market Trends:

The metal injection molding market is characterized by a dynamic interplay of technological innovation, expanding application breadth, and evolving industry priorities. One of the most significant trends is the integration of advanced materials and AI-driven process optimization, which is enhancing the performance, reliability, and cost-effectiveness of MIM components. The market is witnessing a pronounced shift toward the production of lightweight, high-strength, and miniaturized parts, particularly in automotive, electronics, and medical sectors, where precision and complexity are paramount. Sustainability is emerging as a critical driver, with manufacturers adopting eco-friendly feedstocks and optimizing processes to reduce material waste and energy consumption.

The growing demand for mass customization and rapid prototyping is fueling the adoption of MIM in new product development cycles, enabling faster time-to-market and greater design flexibility. Regionally, Asia-Pacific continues to lead market growth, supported by large-scale manufacturing capabilities and a thriving electronics and automotive industry, while North America and Europe are focusing on high-value applications and technological leadership. Strategic collaborations, mergers, and investments in R&D are further intensifying competition and accelerating innovation. As industries increasingly prioritize efficiency, sustainability, and advanced functionality, the metal injection molding market is poised for sustained growth, driven by its unique ability to deliver complex, high-performance metal parts at scale.

Do you know more information, Contact to our analyst at- https://www.imarcgroup.com/metal-injection-molding-market

Key Market Segmentation:

Breakup by Material Type:

• Stainless Steel

• Low Alloy Steel

• Soft Magnetic Material

• Others

Stainless steel leads due to its corrosion resistance and high strength, suiting a broad range of intricate part applications.

Breakup by End Use Industry:

• Electrical and Electronics

• Automotive

• Medical and Orthodontics

• Consumer Products

• Firearms and Defense

• Others

The electrical & electronics sector dominates as metal injection molding (MIM) meets the demand for miniaturized, complex components in electronic devices.

Breakup by Region:

• North America (United States, Canada)

• Asia Pacific (China, Japan, India, Australia, Indonesia, Korea, Others)

• Europe (Germany, France, United Kingdom, Italy, Spain, Others)

• Latin America (Brazil, Mexico, Others)

• Middle East and Africa (United Arab Emirates, Saudi Arabia, Qatar, Iraq, Other)

Asia Pacific holds the largest market share with its extensive manufacturing base and increased adoption of MIM across diverse industries.

Key Highlights of the Report:

• Market Performance (2019-2024)

• Market Outlook (2025-2033)

• Porter's Five Forces Analysis

• Market Drivers and Success Factors

• SWOT Analysis

• Value Chain

• Comprehensive Mapping of the Competitive Landscape

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Who we are:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Injection Molding Market To Hit USD 9.5 Billion by 2033 | CAGR of 8.21% here

News-ID: 4097315 • Views: …

More Releases from IMARC Group

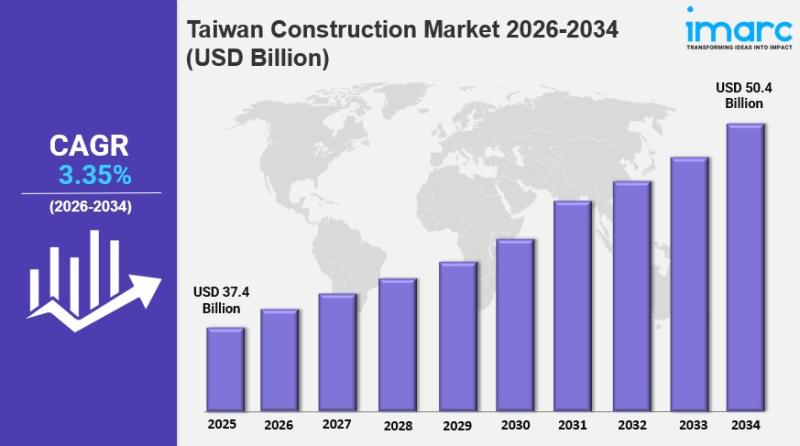

Taiwan Construction Market Size, Share, In-Depth Insights, Trends and Forecast 2 …

IMARC Group has recently released a new research study titled "Taiwan Construction Market Report by Sector (Residential, Commercial, Industrial, Infrastructure (Transportation), Energy and Utilities Construction), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Taiwan construction market size reached USD 37.4 Billion in 2025 and is projected to grow to USD 50.4…

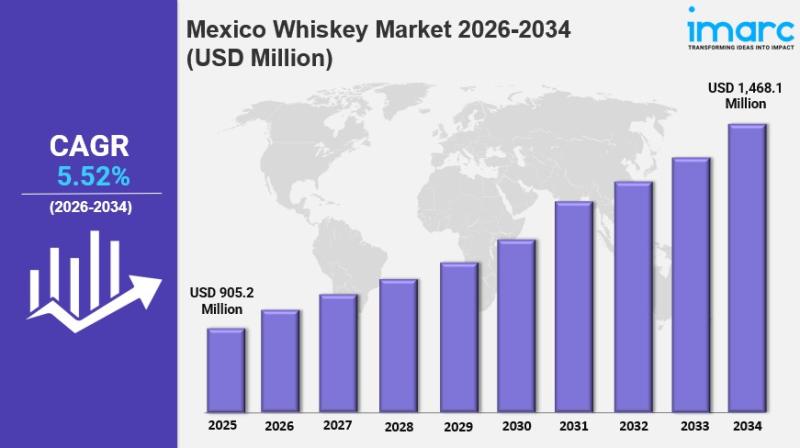

Mexico Whiskey Market Size to Hit USD 1,468.1 Million by 2034: Trends & Forecast

IMARC Group has recently released a new research study titled "Mexico Whiskey Market Size, Share, Trends and Forecast by Product Type, Quality, Distribution Channel, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico whiskey market size reached USD 905.2 Million in 2025. It is projected to grow to USD 1,468.1 Million…

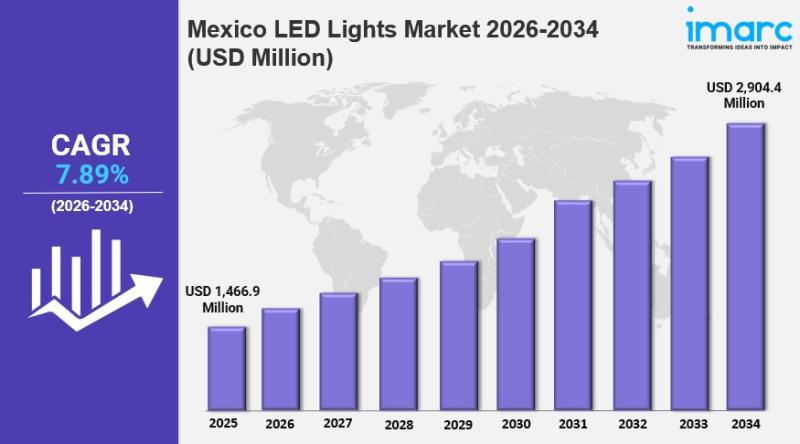

Mexico LED Lights Market 2026 : Industry Size to Reach USD 2,904.4 Million by 20 …

IMARC Group has recently released a new research study titled "Mexico LED Lights Market Size, Share, Trends and Forecast by Product Type, Application, Import and Domestic Manufacturing, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico LED lights market was valued at USD 1,466.9 million in 2025 and is projected to…

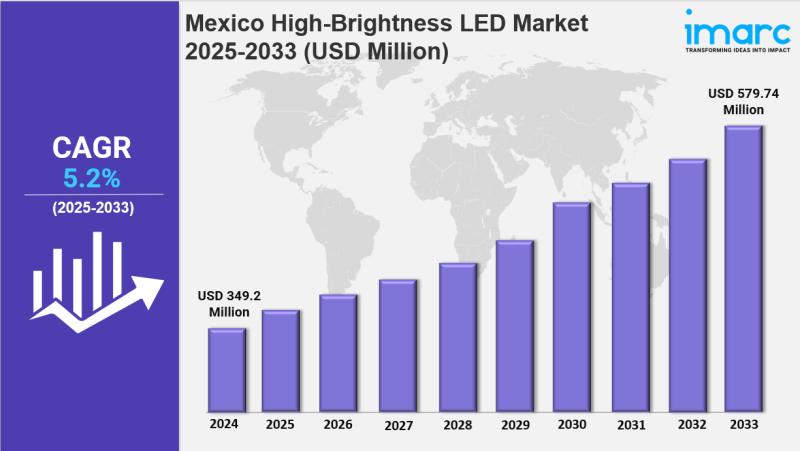

Mexico High-Brightness LED Market Size, Share, Latest Insights and Forecast 2025 …

IMARC Group has recently released a new research study titled "Mexico High-Brightness LED Market Size, Share, Trends and Forecast by Application, Distribution Channel, Indoor and Outdoor Application, End-Use Sector, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico high-brightness LED market size reached USD 349.2 Million in 2024 and is…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…