Press release

Aluminum Castings Industry to Grow at 6.6% CAGR Through 2034

The global aluminum castings market, valued at USD 41.5 billion in 2023, is projected to reach USD 83.4 billion by 2034, expanding at a compound annual growth rate (CAGR) of 6.6% from 2024 to 2034. This growth is driven by increasing demand across the automotive, aerospace, and construction sectors due to aluminum's lightweight, corrosion-resistant, and high-strength properties. Technological advancements in casting methods and a shift toward sustainable and energy-efficient materials are also contributing to the market's upward trajectory.Light weight of aluminum coupled with high strength is driving its use in automobiles. Aluminum cast components account for around 30 to 40% of the total weight of the currently manufactured lightweight vehicles. Increase in stringency of regulations on fuel emissions across the globe is likely to further drive the integration of aluminum components in automotive vehicles.

Unlock Full Market Insights: Get a Sample Report Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=31241

Market Segmentation

The aluminum castings market can be segmented based on various factors, providing a comprehensive understanding of its diverse landscape:

By Service Type: While specific data on "service type" segmentation for the overall market is limited, aluminum casting services often include:

Design and Prototyping

Pattern Making

Mold Creation

Melting and Pouring

Cooling and Solidification

Finishing

Quality Control & Inspection

By Sourcing Type: Aluminum sourcing primarily involves:

Primary Aluminum

Secondary Aluminum (Recycled Aluminum)

By Application: The diverse applications of aluminum castings include:

Transportation

Building & Construction

Industrial

Consumer Goods

Electrical Engineering

Packaging

Defense

By Industry Vertical: The market growth is primarily driven by key industry verticals:

Automotive

Aerospace

Construction

Machinery & Equipment

Consumer Electronics

By Region:

Asia Pacific: This region dominates the aluminum castings market, holding over 46% of the revenue share in 2024. Its dominance is attributed to rapid industrialization, particularly in countries like China and India, where the automotive, manufacturing, and construction sectors are expanding swiftly. The region benefits from increasing presence of skilled labor, low labor costs, and easy availability of raw materials.

North America: Contributes significantly to the market, driven by technological advancements and a strong focus on lightweight materials in the automotive and aerospace industries. North America is expected to be the fastest-growing region during the forecast period.

Europe: A major market with stringent emission regulations for vehicles, boosting the demand for lightweight aluminum components. The presence of key automotive manufacturers also contributes to market growth.

Latin America: An emerging market with growing industrial activities.

Middle East and Africa: Showing increasing potential due to infrastructure development and industrialization.

Regional Analysis

The Asia Pacific region is and will continue to be the largest market for aluminum castings, with its size estimated at USD 41.83 billion in 2024 and projected to reach around USD 74.09 billion by 2034, growing at a CAGR of 5.88%. This growth is underpinned by rapid economic development, significant investments in manufacturing and infrastructure, and the booming automotive sector, especially in China and India.

North America is poised for rapid growth due to increasing adoption of advanced manufacturing technologies and the strong emphasis on light weighting in the automotive and aerospace industries. Europe also holds a substantial share, driven by its mature automotive industry and strict environmental regulations.

Market Drivers and Challenges

Market Drivers:

Growing Demand for Lightweight Vehicles: The automotive industry's shift towards electric vehicles (EVs) and the increasing need for fuel-efficient conventional cars are major drivers. Aluminum's lightweight properties are crucial for offsetting battery weight in EVs and improving overall fuel economy and performance.

Technological Advancements in Casting: Innovations in casting technologies, such as high-pressure die casting (HPDC), advancements in additive manufacturing (3D printing), and automation, are improving production efficiency, precision, and the quality of aluminum castings.

Increasing Applications in Aerospace and Construction: The demand for lightweight, durable components in the aerospace industry for improved fuel efficiency and in the construction sector for sustainable and easy-to-install materials continues to drive market growth.

Rising Disposable Income and Urbanization: Particularly in emerging economies, these factors lead to increased demand for consumer goods and infrastructure development, boosting the need for aluminum castings.

Sustainability Initiatives: The recyclability of aluminum aligns with global sustainability goals, driving its adoption as manufacturers focus on reducing carbon footprints and waste.

Market Challenges:

High Initial Investment: Setting up and upgrading aluminum casting facilities requires substantial capital investment, which can be a barrier for new entrants and a challenge for existing players.

Environmental Regulations: Stringent environmental policies regarding emissions and waste management during the casting process pose compliance challenges and necessitate significant investment in sustainable innovations and technologies. The energy-intensive nature of primary aluminum production is also a concern.

Competition from Alternative Materials: Materials such as magnesium alloys, composites, and advanced plastics offer competitive advantages in specific applications, potentially limiting the market penetration of aluminum castings.

Supply Chain Disruptions: Volatility in raw material prices (bauxite, aluminum) and disruptions in the global supply chain can impact production efficiency and market demand.

Market Trends

Sustainability as a Core Business Strategy: Companies are increasingly focusing on recycling aluminum, adopting energy-efficient production methods, and investing in sustainable practices throughout the value chain.

Integration of Smart Manufacturing Technologies (Industry 4.0): The incorporation of automation, IoT (Internet of Things), AI, and digital twins is transforming the aluminum casting industry, leading to improved accuracy, efficiency, process optimization, and predictive maintenance.

Innovation in Aluminum Alloys: Development of high-strength aluminum alloys (e.g., Aluminum-Zinc, Aluminum-Magnesium) for enhanced performance, particularly in aerospace and automotive sectors, where structural integrity and weight reduction are critical.

Expansion of Customization Capabilities: Rising demand for bespoke solutions in industries like automotive and aerospace is driving manufacturers to offer greater design flexibility and rapid prototyping.

Focus on Energy Efficiency in Production: Innovations in furnace technologies and process optimization are aimed at reducing energy consumption and lowering production costs.

Additive Manufacturing (3D Printing) Integration: The use of 3D printing in aluminum casting allows for the production of complex parts with reduced material waste and enhanced design flexibility, especially for prototyping and small-batch production.

Future Outlook

The future of the aluminum castings market appears promising, driven by continued innovation and the increasing global emphasis on lightweighting and sustainability. The surge in electric vehicle production will be a primary growth lever, as aluminum remains crucial for improving battery efficiency and vehicle range. Further advancements in casting technologies, alloy development, and automation will contribute to enhanced efficiency and expanded applications. The market is expected to witness continued investment from both public and private sectors, fueling innovation and capacity expansion.

Key Market Study Points

Dominance of Die Casting: The die casting segment is expected to remain the largest process type due to its ability to produce high-precision parts rapidly and cost-effectively, particularly for the automotive industry.

Transportation Sector Leadership: The transportation application segment will continue to hold the largest market share, driven by the automotive and aerospace industries.

Asia Pacific as the Growth Engine: The region's rapid industrialization and manufacturing expansion will solidify its position as the largest and fastest-growing market.

Impact of EV Revolution: The transition to electric vehicles is a significant market driver, pushing demand for aluminum battery housings and structural components.

Sustainability and Recycling: The shift towards a circular economy and the emphasis on recycled aluminum will be critical for market growth and competitive advantage.

Technological Adoption: Companies that embrace advanced manufacturing techniques like Industry 4.0, digital twins, and additive manufacturing will gain a competitive edge.

Competitive Landscape

The aluminum castings market is characterized by the presence of several key players, ranging from global giants to regional champions. These companies are actively investing in R&D, expanding their facilities, and adopting strategic initiatives like mergers and acquisitions to enhance their market presence and product offerings.

Key players in the market include:

Alcoa Corporation

Nemak S.A.B. de C.V.

Aluminum Corporation of China Limited

Ryobi Limited

Dynacast

Endurance Technologies Ltd.

Gibbs Die Casting Corporation

Consolidated Metco, Inc. (ConMet)

Shiloh Industries, Inc.

Rio Tinto

Norsk Hydro ASA

Martinrea Honsel Germany GmbH

Bodine Aluminum, Inc.

Alcast Technologies Ltd.

These companies compete on factors such as technological expertise, production capacity, product quality, cost-efficiency, and adherence to environmental standards.

Recent Developments

Recent developments in the aluminum castings industry highlight a strong trend towards innovation, sustainability, and strategic expansion:

Facility Expansions and Acquisitions: Companies are actively expanding their production capabilities and acquiring other businesses to meet escalating demand and broaden their market reach. For instance, in February 2024, ADC Aerospace acquired Cast Rite Metal Company to enhance its product offerings and market penetration.

Investment in Advanced Die Casting Lines: Significant investments are being made in advanced die-casting lines, particularly for electric vehicle components like battery housings and structural frames.

Focus on Automated Processes: The industry is increasingly adopting automation, robotics, and AI to improve efficiency, accuracy, and worker safety in casting operations.

Development of Specialized Alloys: Continuous research and development are leading to the creation of new and enhanced aluminum alloys with superior properties for specific applications.

Partnerships for Sustainable Manufacturing: Collaborations among companies are emerging to promote sustainable aluminum manufacturing practices, including efforts to increase recycling and reduce carbon footprints.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=31241<ype=S

The aluminum castings market is on a robust growth trajectory, driven by strong demand from key end-use industries and continuous technological advancements. While challenges related to initial investment and environmental regulations persist, the industry's commitment to innovation and sustainability positions it for significant expansion in the coming decade.

Explore Latest Research Reports by Transparency Market Research:

Industrial Silica Market - https://www.transparencymarketresearch.com/industrial-silica-sands-market.html

Specialty Silica Market - https://www.transparencymarketresearch.com/specialty-silica-market.html

Aluminum Market - https://www.transparencymarketresearch.com/aluminum-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Castings Industry to Grow at 6.6% CAGR Through 2034 here

News-ID: 4038583 • Views: …

More Releases from transparencymarketresearch

Microgreens Market to Surge at 10.9% CAGR, Set to Reach USD 8.56 Billion by 2036

The global microgreens market was valued at USD 2,780.5 million in 2025 and is projected to reach USD 8,563.5 million by 2036. Driven by rising demand for nutrient-dense foods and growing adoption across foodservice and retail channels, the industry is expected to expand at a robust CAGR of 10.9% from 2026 to 2036.

The global microgreens market represents a specialized, high-value segment within the broader fresh produce and specialty horticulture industry,…

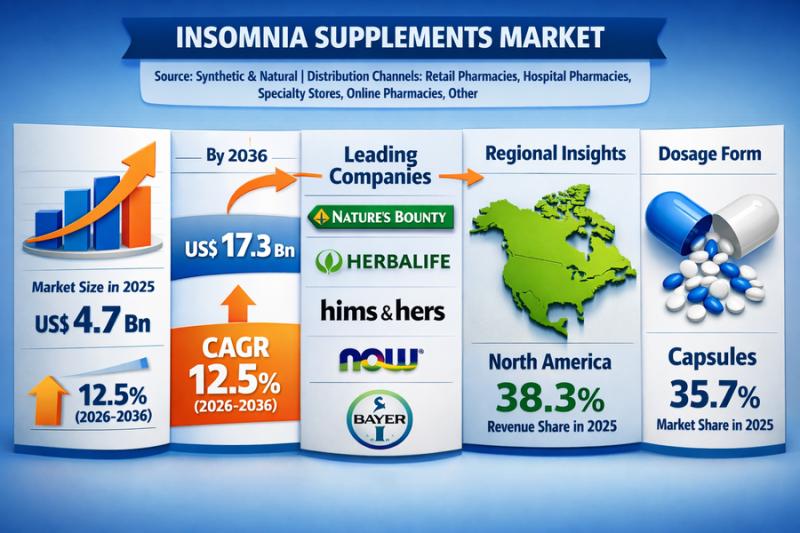

Insomnia Supplements Market Set to Reach US$ 17.3 Bn by 2036, Growing at a Robus …

The global insomnia supplements market was valued at USD 4.7 billion in 2025 and is projected to reach USD 17.3 billion by 2036, reflecting strong growth potential. The market is anticipated to expand at a CAGR of 12.5% from 2026 to 2036, driven by rising sleep disorder prevalence, increasing consumer focus on mental wellness, and growing demand for natural and non-prescription sleep aids.

The insomnia supplements market is expected to witness…

Fiber-Based Blister Pack Market Set to Surge at 21.5% CAGR Through 2036

The global fiber-based blister pack market was valued at US$ 1,633.8 million in 2025 and is projected to surge to US$ 13,591.8 million by 2036. Driven by rising demand for sustainable and eco-friendly packaging solutions, the market is expected to grow at a robust CAGR of 21.5% from 2026 to 2036.

Fiber-based blister packaging is a type of packaging that substitutes the usual plastic blister with paperboard or molded fiber components…

Psychotropic Drugs Market to Reach US$ 41.2 Bn by 2036, Growing at 5.4% CAGR

The global psychotropic drugs market was valued at USD 23.1 Bn in 2025 and is projected to reach USD 41.2 Bn by 2036. Driven by rising awareness of mental health disorders, increasing diagnosis rates, and ongoing pharmaceutical innovations, the industry is expected to grow at a CAGR of 5.4% from 2026 to 2036.

The primary drivers of the expanding psychotropic drugs market include the rising prevalence of mental disorders such as…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…