Press release

Particle free Laser Trimming of Micro Mirror Devices

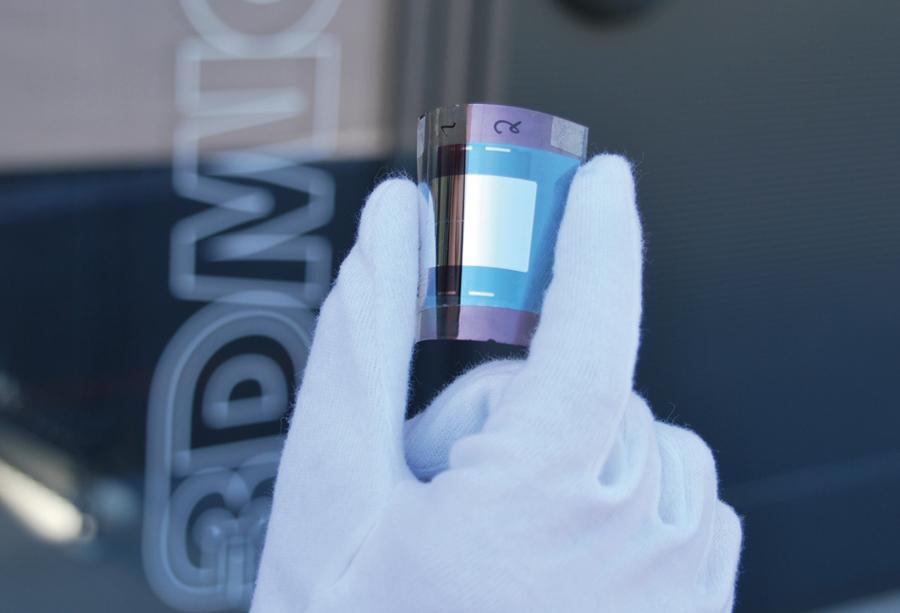

MEMS fabrication technologies cause tolerances in device dimensions and consequently on key parameters like the resonant frequency. In contrast to these manufacturing tolerances industrial applications require defined conditions.Therefore 3D-Micromac AG has developed an industrial-applicable laser-trimming tool to overcome these tolerances. The processing of Silicon in particular Micro Mirror Devices (MMD) by ultra-short pulse is accom-panied by a very small heat affected zone and causes a minimum of stress into the material. The trimming of all MMDs on a wafer to a certain frequency value is performed by selective ablation of material. The reported technology promises an increasing yield and maximizes the efficiency in MEMS production because a post fabrication tuning of the resonant frequency by software is no longer necessary.

The main goal is to trim all mirror elements on a wafer. Additional trimming elements at frequency influencing mirror components enable a trimming of mirrors to a certain frequency value. The laser cutting of trimming elements at the torsion spring effects a frequency decrease because of lowering beam stiffness while the removal of mass trimming elements at the mirror plate increases frequency by mass reduction. The contami-nation with particles is reduced by processing in fine vacuum and bonding and reflecting areas of the MMD remain clean.

The new laser-tool, which has been developed in collaboration with the Center for Microtechnologies of Technical University of Chemnitz, enables the measurement and trimming of MMDs on a wafer and simpli-fies the industrial use.

Femtosecond laser sources suit the application as well as picosecond laser sources but a picosecond laser workstation is the first choice because of its higher repetition rate for the development of a suitable system for industrial use.

The laser trimming technique is not limited to Silicon Micro Mirror Devices. It also fits all kinds of sensors and actuators and suits a large variety of materials, for instance ceramics.

Frequency trimming of MEMS devices is a promising approach to overcome these manufacturing tolerances, to tune sensors and actuators for certain operating conditions and it promises an increasing yield in MEMS technology.

Further information and pictures:

3D-Micromac AG

Dipl.-Betriebswirt (BA) Mandy Möckel

Marketing/ Sales

Annaberger Str. 240

D-09125 Chemnitz

GERMANY

Phone: +49 (0)371 400 43-0

Fax: +49 (0)371 400 43-40

E-Mail: info@3d-micromac.com

Web: http://www.3d-micromac.com

About 3D-Micromac AG

3D-Micromac AG, a leading supplier of customized laser micro machining systems, has gained an estab-lished position in the international market over the past several years.

As a developer and manufacturer of complex workstations, as a service provider for materials and surface machining or as a solution provider for the development of specific production processes - we are able to find the best solution for every customer’s task.

More: http://www.3d-micromac.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Particle free Laser Trimming of Micro Mirror Devices here

News-ID: 39922 • Views: …

More Releases from 3D-Micromac AG

Increase in efficiency for thin-film solar modules: 3D-Micromac launches an inno …

Chemnitz, 03 June 2013. This June, 3D-Micromac from Chemnitz (Germany) will launch the first production equipment worldwide that can conduct the integrated series-connection of a thin-film solar module on one single platform and in one single production step. The new One-Stop-Patterning process (OSP) only structures the modules once all of the functional layers have been deposited on the substrate. This significantly simplifies the production process. In addition, the new…

3D-Micromac receives „Green Photonics Award 2011“

SPIE honors research in the field of organic photovoltaics

On January 26, 2011 3D-Micromac was honored with the “SPIE 2011 Green Photonics Award”. Tino Petsch, CEO of 3D-Micromac received the prize for the scientific publication “Laser processing of organic solar cells in a roll-to-roll manufacturing process” at the “Photonics West” in San Francisco. With this award, SPIE pays tribute to the outstanding research work of the company in the field of…

ISL 2010 - International Symposium on Laser-Micromachining at 3D-Micromac taking …

Experts in the field of laser micromachining meet at ISL 2010 in Chemnitz, Germany for the third time

Following the success of the ISL 2008 – 2nd International Symposium on Laser-Micromachining taken place in Chemnitz, Germany and ISL 2009 Asia held in HongKong, China, we are pleased to announce the ISL 2010 – 3rd International Symposium on Laser-Micromachining which will take place in Chemnitz, Germany on 27th – 28th October,…

ISL 2008 - 2nd International Symposium on Laser-Micromachining at 3D-Micromac AG

Experts in the field of laser micromachining meet at ISL 2008 in Chemnitz, Germany at second time

In the last years laser technologies not only confirmed their outstanding role for micro-machining but expanded it impressively. With enhancements in the areas of shorter pulses and shorter wavelengths there are growing possibilities to generate micro structures in all manufacturing sectors.

Applications related to practice and latest trends will be presented by laser manufacturers and…

More Releases for Micro

Micro Injection Molded Plastic Market worth $1,692 million by 2026 | Key players …

According to recent market research "Micro Injection Molded Plastic Market by Material Type (Liquid-Crystal Polymer (LCP), Polyether (PEEK), Polycarbonate (PC), Polyethylene (PE), Polyoxymethylene (POM)), Application and Region - Global Forecast to 2026", published by MarketsandMarkets, the micro injection molded plastic market is projected to reach USD 1,692 million by 2026, at a CAGR of 11.2% from USD 995 million in 2021.

Browse 193 market data Tables and 61 Figures spread through…

Micro Combined Heat & Power (Micro CHP) Market 2022 | Detailed Report

The Micro Combined Heat & Power (Micro CHP) research report combines vital data incorporating the competitive landscape, global, regional, and country-specific market size, market growth analysis, market share, recent developments, and market growth in segmentation. Furthermore, the Micro Combined Heat & Power (Micro CHP) research report offers information and thoughtful facts like share, revenue, historical data, and global market share. It also highlights vital aspects like opportunities, driving, product scope,…

Micro-Invasive Glaucoma Implants Micro-Invasive Glaucoma Implants

Global Micro-Invasive Glaucoma Implants Market Definition: Micro-invasive glaucoma implants is performed for the treatment of the open- angle glaucoma and is done through an ab- interno approach. It is very safe and provides faster recovery as compared to the traditional methods. They usually lower the intraocular by increasing the flow or reducing the production of the aqueous humor. Increasing cases of the glaucoma worldwide is the major factor fueling the…

Global Micro Electric Automotive (Micro EVs) Market Growth 2019-2024

Market Research Report Store offers a latest published report on Micro Electric Automotive (Micro EVs) Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Micro Electric Automotive (Micro EVs) market will register a 5.5% CAGR in terms of revenue, the global market size will reach US$ 9062.2 million by 2024, from…

Global Micro Welding Equipments Market- Growing Popularity and Emerging Trends i …

Welding is a fusion of the two workpieces of the surface to form one, is a precise, reliable, cost-effective and high tech method for joining material. Micro welding is a process that is specifically designed for the welding of small often delicate components. It is also known as precision welding. The process sets up the weld by depositing fine blobs of weld to the components to be fused. The process…

Comprehensive Analysis On Micro Welding Equipment Market 2019 : Pro-Fusion, OR L …

Up Market Research added a new Micro Welding Equipment Market research report for the period of 2019 – 2026. Report focuses on the major drivers and restraints providing analysis of the market share, segmentation, revenue forecasts and geographic regions of the market.

Get Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/108038

The report contains 112 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing…