Press release

How to Setup an Autoclaved Aerated Concrete Manufacturing Plant

Setting up an autoclaved aerated concrete manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Autoclaved Aerated Concrete Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing an autoclaved aerated concrete manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Autoclaved Aerated Concrete (AAC) is a lightweight building material designed to improve construction efficiency and performance. It is made from cement, lime, sand, gypsum, aluminum powder, and water, consisting of a porous structure formed through a chemical reaction. It comes in different types, including blocks, panels, lintels, slabs, and cladding elements, each suited for various applications. AAC is widely used in residential buildings, commercial complexes, industrial units, schools, hospitals, hotels, infrastructure projects, partition walls, and roofing systems. It offers benefits including cost-efficiency, energy savings, and design flexibility, contributing to faster and cleaner construction. It also provides fire resistance, sound insulation, seismic durability, and recyclability, supporting sustainable building practices and making it a preferred choice in modern construction.

The Autoclaved Aerated Concrete (AAC) market is primarily driven by the growing demand for sustainable and energy-efficient building materials, as construction professionals seek reliable and high-performance solutions to meet modern building standards. In addition, the expanding construction sector, with increasing residential, commercial, and infrastructure projects, is fueling the need for lightweight and durable materials and supporting the market growth. Moreover, the rising cost of traditional construction resources is encouraging the shift toward cost-effective alternatives like AAC, contributing to the market expansion. Besides this, ongoing advancements in AAC production, such as automated manufacturing processes and enhanced material formulations, are improving product quality and availability, which is aiding the market growth. Concurrently, the rising adoption of modular and prefabricated construction methods is offering speed and efficiency benefits to builders, thus strengthening the market share. In confluence with this, the growing demand for fire-resistant and sound-insulated materials in schools, hospitals, and hotels is impelling the market growth. Furthermore, the rapid growth of urban housing developments, particularly in emerging economies, is providing an impetus to the market. Apart from this, the increasing use of AAC in commercial projects, driven by the need for fast-track and low-maintenance construction, is making a significant impact, thereby propelling the market forward.

Request for a Sample Report: https://www.imarcgroup.com/autoclaved-aerated-concrete-manufacturing-plant-project-report/requestsample

Key Steps Required to Set Up an Autoclaved Aerated Concrete Plant.

1. Market Analysis

The report provides insights into the landscape of the autoclaved aerated concrete industry at the global level. The report also provides a segment-wise and region-wise breakup of the global autoclaved aerated concrete industry.

Additionally, it also provides the price analysis of feedstocks used in the manufacturing of autoclaved aerated concrete, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the autoclaved aerated concrete manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Buy Now: https://www.imarcgroup.com/checkout?id=30614&method=1911

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for the autoclaved aerated concrete manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for autoclaved aerated concrete production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=30614&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up an autoclaved aerated concrete manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Setup an Autoclaved Aerated Concrete Manufacturing Plant here

News-ID: 3971105 • Views: …

More Releases from IMARC Group

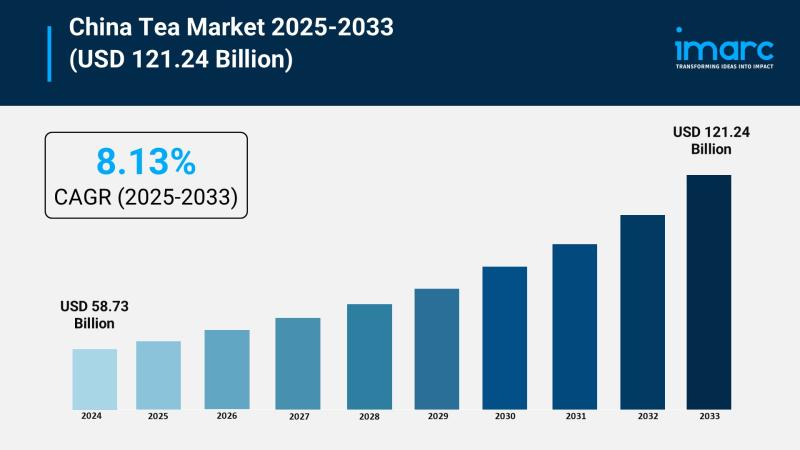

China Tea Market Forecast CAGR of 8.13%, Innovation Trends, and Strategic Insigh …

Market Overview

The China tea market was valued at USD 58.73 Billion in 2024 and is projected to reach USD 121.24 Billion by 2033, growing at a CAGR of 8.13% during 2025-2033. Growth is driven by rising health consciousness, premium product trends, government support, and expanding online retail. Innovation in flavors and packaging attracts younger consumers and global buyers, expanding the market.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

China Tea…

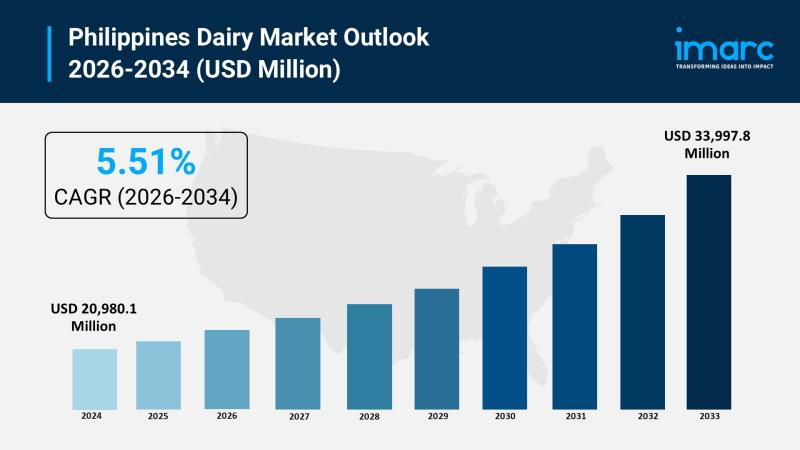

Philippines Dairy Market 2026: Expected to Reach USD 33,997.8 Million by 2034

Market Overview

The Philippines dairy market reached a size of USD 20,980.1 Million and is anticipated to grow to USD 33,997.8 Million by 2034 with a significant growth rate of 5.51%. This expansion is driven by rising demand for nutritious and diverse dairy products, rapid urbanization, increased disposable incomes, improved retail infrastructure, and strong government initiatives promoting local dairy production. Health-conscious consumers and expanding food service sectors further fuel this growth…

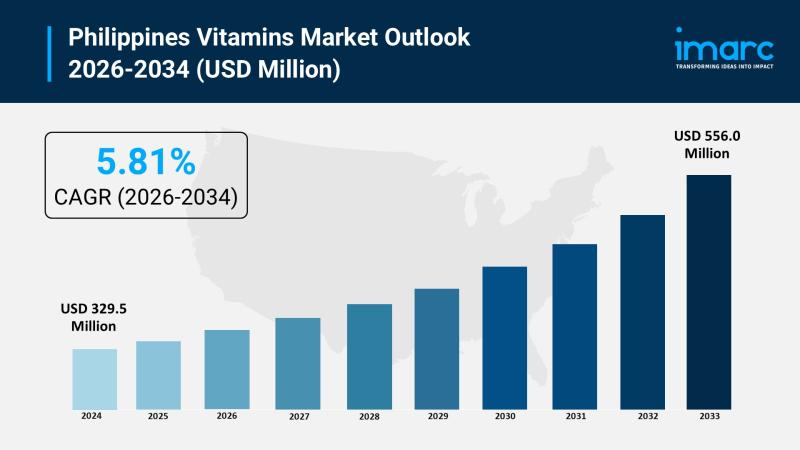

Philippines Vitamins Market 2026 | Projected to Reach USD 556.0 Million by 2034

Market Overview

The Philippines vitamins market was valued at USD 329.5 Million in 2025 and is projected to reach USD 556.0 Million by 2034, growing steadily over the forecast period. The market's growth is driven by increasing health consciousness, a rising geriatric population, and escalating demand for supplements that support immunity, energy, and overall wellness due to proactive health measures. The forecast period for this expansion is 2026-2034, with a CAGR…

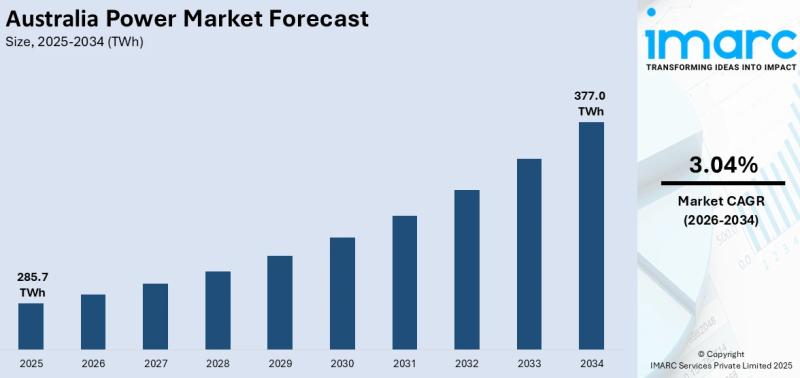

Australia Power Market Projected to Reach TWH 377 by 2034

Market Overview

The Australia power market size reached 285.7 TWh in 2025 and is projected to grow to 377.0 TWh by 2034, with a CAGR of 3.04% during the forecast period of 2026-2034. This growth is driven by rising renewable energy adoption, increased electricity demand, grid modernization, battery storage expansion, transition from coal plants, and government incentives for clean power. Key strategies such as virtual power plant integration and investments in…

More Releases for Autoclaved

Green Building Construction Driving Growth In The Autoclaved Aerated Concrete Ma …

Stay ahead with our updated market reports featuring the latest on tariffs, trade flows, and supply chain transformations.

How Large Will the Autoclaved Aerated Concrete Market Size By 2025?

The market size of autoclaved aerated concrete has seen significant expansion in the past few years. It is projected to increase from $16.9 billion in 2024 to $18.49 billion in 2025, demonstrating a compound annual growth rate (CAGR) of 9.4%. Factors that contributed…

Autoclaved Lightweight Concrete (ALC) Blockss as Currency: Exploring the Global …

Los Angeles, United States - In this comprehensive research study, we delve into the intricate details of the global Autoclaved Lightweight Concrete (ALC) Blocks market, providing a thorough analysis of its critical aspects. The report illuminates the anticipated growth of the global Autoclaved Lightweight Concrete (ALC) Blocks market during the forecast period, supported by SWOT analysis and Porter's Five Forces analysis. This illumination includes an in-depth exploration of the market's…

Autoclaved Aerated Concrete (AAC) Market - Encouraging Transformation 2027

Autoclaved aerated concrete (AAC) is a concrete based product which has distinct cellular structure that features enormous tiny pockets of trapped air. It is an eco-friendly building material which is lightweight and, concrete. It is also termed as autoclaved cellular concrete (ACC) and autoclaved lightweight concrete (ALC).The production of AAC involves the use raw materials such as fly ash which is the residue of thermal power plants. AAC is preferred…

Autoclaved Aerated Concrete (AAC) Market Analysis & Trends 2027

Albany, NY - The drive for green construction materials is a key driver for the growing popularity of autoclave aerated concrete (AAC) products. They have been used widely in floors, walls, and roofs, and an array of products have gained traction over the years, underpinned mainly by the structural and design flexibility AAC offers.

Read Report - https://www.transparencymarketresearch.com/autoclaved-aerated-concrete-market.html

Material and Performance Characteristics Makes Autoclaved Aerated Concrete (AAC) Material of Choice

The growing shipping of AAC…

Autoclaved Aerated Concrete (AAC) Market Analysis & Trends 2027

Albany, NY - Key Highlights

According to a new market report published by Transparency Market Research titled ‘Autoclaved Aerated Concrete Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2019–2027,’ the global autoclaved aerated concrete market was valued at around US$ 11.9 Bn in 2018 and is projected to reach nearly US$ 22.8 Bn by 2027, expanding at a CAGR of above 7% between 2019 and 2027.

Autoclaved aerated concrete…

Autoclaved Aerated Concrete Market Demand and Forecast 2030

The “Autoclaved Aerated Concrete Market Analysis to 2030” is a specialized and in-depth study of the Autoclaved Aerated Concrete industry with a focus on the Autoclaved Aerated Concrete market trend. The report aims to provide an overview of the Autoclaved Aerated Concrete market with detailed market segmentation by component, application, end-user, and geography. The Autoclaved Aerated Concrete market is expected to witness high growth during the forecast period. The report…