Press release

6063 T6 Aluminum Profile for New Energy Vehicle Battery Casing: The Future of Electric Vehicle Battery Enclosures

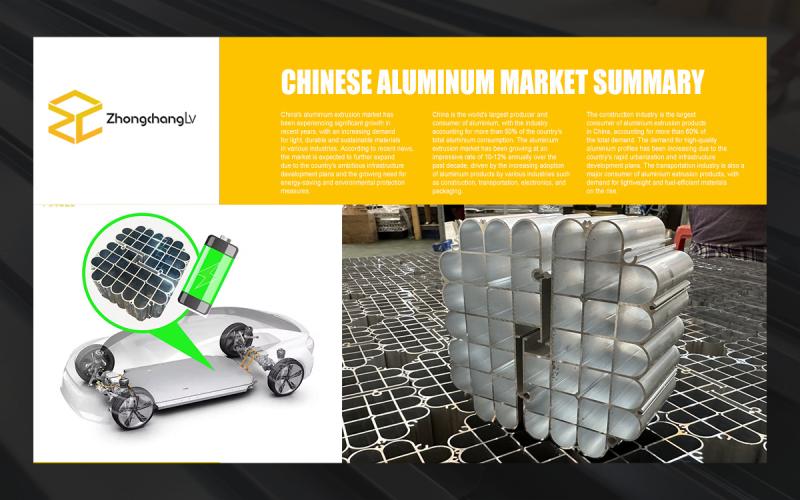

The rapid advancement of electric vehicles (EVs) has brought about a surge in demand for high-performance battery enclosures. As the automotive industry shifts towards sustainable and eco-friendly transportation solutions, the need for lightweight, durable, and efficient battery enclosures has become increasingly crucial. This is where 6063 T6 aluminum profile for new energy vehicle battery casing comes into play, offering a cutting-edge solution for the development of next-generation EV battery enclosures.Aluminum extrusion has long been recognized as a versatile and cost-effective manufacturing process for creating complex shapes with excellent structural integrity. When applied to the production of electric vehicle battery enclosures, aluminum extrusion offers numerous advantages, including high strength-to-weight ratio, corrosion resistance, and exceptional thermal conductivity. These properties make it an ideal material for ensuring the safety, performance, and longevity of EV battery systems.

Image: https://ecdn6.globalso.com/upload/p/786/image_other/2024-03/65fd302193d9a45888.jpg

The 6063 T6 aluminum profile, specifically designed for new energy vehicle battery casing, is engineered to meet the stringent requirements of modern EV applications. Its high tensile strength and superior formability allow for the creation of intricate and customized designs, enabling manufacturers to optimize the shape and structure of battery enclosures for maximum efficiency. Additionally, the T6 temper designation signifies that the aluminum alloy has undergone a solution heat treatment and artificial aging process, resulting in enhanced mechanical properties and improved resistance to deformation.

One of the key benefits of utilizing aluminum extrusion for electric vehicle battery enclosures is the ability to achieve lightweight yet robust designs. As the automotive industry continues to prioritize energy efficiency and range optimization, reducing the weight of battery enclosures is paramount. The 6063 T6 aluminum profile offers a compelling solution by enabling the creation of intricate and hollow cross-sectional profiles, minimizing material usage without compromising structural integrity. This not only contributes to the overall weight reduction of EVs but also enhances their driving range and performance.

Moreover, the exceptional thermal conductivity of aluminum makes it an ideal choice for dissipating heat generated during battery operation. Efficient thermal management is critical for maintaining the optimal operating temperature of EV batteries, as excessive heat can degrade performance and shorten the lifespan of the battery cells. By utilizing 6063 T6 aluminum profiles in the construction of battery enclosures, manufacturers can leverage the material's superior thermal conductivity to effectively dissipate heat, ensuring the long-term reliability and safety of the battery system.

Image: https://ecdn6.globalso.com/upload/p/786/image_other/2024-03/65fd30a72d1c812742.jpg

In addition to its mechanical and thermal properties, aluminum extrusion offers unparalleled design flexibility, allowing for the integration of various features and components within the battery enclosure. This includes the seamless incorporation of mounting brackets, cooling channels, and structural reinforcements, enabling the creation of highly functional and integrated battery housing solutions. Furthermore, the ability to achieve complex geometries and precise tolerances through aluminum extrusion facilitates the seamless integration of battery enclosures into the overall vehicle architecture, optimizing space utilization and enhancing overall vehicle performance.

The adoption of 6063 T6 aluminum profiles for new energy vehicle battery casing also aligns with the industry's sustainability goals. Aluminum is fully recyclable, and its lightweight nature contributes to the overall energy efficiency of electric vehicles. By choosing aluminum extrusion for battery enclosures, automakers can reduce the environmental impact of their vehicles while simultaneously enhancing their performance and safety.

Looking ahead, the demand for advanced battery enclosures for electric vehicles is expected to grow exponentially as the global automotive industry transitions towards electrification. The development and utilization of 6063 T6 aluminum profiles for new energy vehicle battery casing represent a significant step towards meeting this demand, offering a compelling solution that combines lightweight construction, exceptional strength, and efficient thermal management.

In conclusion, the application of 6063 T6 aluminum profiles [https://www.zc-aluminum.com/aluminum-extrude-high-quality-6063-powder-coating-aluminum-fence-column-profile-product/] through aluminum extrusion for electric vehicle battery enclosures represents a pivotal advancement in the development of next-generation EVs. By harnessing the unique properties of aluminum, manufacturers can create battery enclosures that are not only lightweight and durable but also highly efficient in managing thermal loads. As the automotive industry continues to embrace sustainable mobility solutions, the utilization of aluminum extrusion for new energy vehicle battery casing is poised to play a pivotal role in shaping the future of electric transportation.

Media Contact

Company Name: Foshan Zhongchang Aluminium Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=6063-t6-aluminum-profile-for-new-energy-vehicle-battery-casing-the-future-of-electric-vehicle-battery-enclosures]

Country: China

Website: https://www.zc-aluminum.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release 6063 T6 Aluminum Profile for New Energy Vehicle Battery Casing: The Future of Electric Vehicle Battery Enclosures here

News-ID: 3441509 • Views: …

More Releases from ABNewswire

Mind Above Matter Expands Access to Mental Health Support with Virtual Group The …

Mind Above Matter in Keller, TX, is enhancing access to mental health care by offering virtual group therapy sessions. This expansion allows individuals to receive professional support from the comfort of their homes, making mental health services more accessible and convenient for the community.

Keller, TX - Dec 19, 2025 - Mind Above Matter, a leading provider of outpatient group treatment services in Keller, TX, is expanding its mental health support…

Mahogany Kitchens Discusses the Growing Demand for Custom Cabinetry in Palm Beac …

Mahogany Kitchens highlights the growing preference for tailored cabinetry in Palm Beach County, covering local trends in kitchen remodeling and handcrafted woodwork solutions.

Palm Beach County has seen a notable shift in how homeowners approach interior design, with a growing preference for custom cabinetry that reflects personal style and functional needs. Mahogany Kitchens, a Boynton Beach-based woodwork company, has observed this trend firsthand while serving clients throughout South Florida. The increased…

Prince Health Introduces PlaqueX IV Therapy in The Woodlands for Cardiovascular …

Prince Health in The Woodlands, TX, announces the launch of PlaqueX IV therapy, a non-surgical functional medicine treatment designed to support heart health and reduce arterial plaque. Led by Dr. Ashley Prince, DC, the practice offers this advanced phosphatidylcholine infusion to help patients improve circulation and lipid metabolism. This proactive cardiovascular solution is now available to residents in the Greater Houston area.

THE WOODLANDS, Texas - December 19, 2025 - Prince…

From London Comforts to Vietnamese Chaos: Author Jane Roberts Unveils the Gritty …

When a high-stakes job offer in Hanoi disrupts a settled life in the UK, one woman abandons her safety net to build a market-leading empire amidst humidity, hardship, and the unknown-proving that true transformation only happens when you stop playing it safe.

In her powerful debut, Follow Your Dreams: Dare to Venture into the Unknown, Jane Roberts brings us a compelling narrative about the transformative power of chasing your dreams, even…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…