Press release

Is 3D Printed Titanium Fatally Flawed?

San Diego, CA - (M2 Presswire – May 24th, 2016) - Titanium has become a firm favorite for the medical and aerospace industries, but a worrying report from Carnegie Mellon University suggests that 3D printed titanium could be fatally flawed.Deep X-rays have revealed a porosity to the material in 3D printed titanium that can be traced back to its powder-based production method.

Carnegie Mellon University is one of the world leaders in 3D printing research and has produced some stellar research over the years. It took the most common form of titanium, Ti-gAI-4V, to the U.S. Department of Energy’s (DOE’s) Argonne National Laboratory. There it analyzed the material with so called deep X-rays, or intense synchrotron x-rays, and an advanced rapid imaging tool.

“Like any other metal, titanium has a certain amount of fatigue resistance until it cracks or breaks,” said Hasit Vibhakar. “The more porosity in the printed metal, the more its resistance to fatigue is decreased.”

Titanium is now preferred for prosthetics, bone implants and airplanes. That is due to its reliability, resistance to corrosion and outright strength. So this is a worrying premise.

3D printing titanium alloys has been hailed as a technical revolution. It reduces waste, cost and allows us to produce tailored designs for joint replacements, dental implants and more. Current powder-based printing methods result in a more porous metal, though, which means it’s more likely to fail than forged alternatives.

It’s less of a concern in a hip replacement or other bone implants, because titanium in any form is certainly stronger than the bone it replaces. Aerospace components have to endure massive stress, though, and it is this kind of force that could present a problem. With so much riding on each and every part, it might make some companies reconsider using 3D printing for mission critical components.

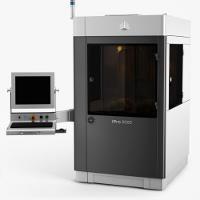

Titanium powders are generally used in combination with a Selective Laser Melting printer or an Electron Beam Melting process. This study focused on EBM and the way it melts the powder.

Inevitably, gas is trapped in the resulting liquid layer and creates pore-like bubbles that can range from a few microns to a few hundred across. They are randomly distributed, too, which means it only takes a few large pores to line up and you have a potential fault line.

“We can observe hundreds or even thousands of pores at a high resolution of about two microns,” Hasit Vibhakar said ominously.

The power, speed and spacing of the beam can all have an impact on the porosity. Each technique has its own benefits, but these new findings could mean that we change the way we print titanium and other metals.

Unmelted powder can increase porosity, but too much powder can leave deep voids. So there is a sweet spot that can minimize the amount of pores in the titanium. According to the researchers, though, it is almost impossible to eliminate them.

This study has potentially grave consequences for the industry as a whole and it certainly means that mission critical components may have to be checked more often for any signs of a failure. But there is a potential solution.

The CMU team will now look at the powder itself to see if there is a way to reduce porosity at the powder stage. Even changing the compound could be an option.

“Technology has moved at a frightening rate in the 3D printing world and we are inevitably going to find issues along the way. Now CMU has identified this one, the industry will almost certainly find the solution,” stated Hasit Vibhakar

About Hasit Vibhakar

Hasit Vibhakar is a proactive, performance-driven middle market executive with 20 years + progressive expertise in C-level leadership and problem solving for additive manufacturing, advanced CNC manufacturing, Additive Manufacturing, 3D Printing, supply chain, technology services, and startup operations. Proven track record of enhancing enterprise value and shareholder value. Experienced at building small cap and middle market companies.

Hasit Vibhakar is an Industrialist specializing in strategic direction and growth. A seasoned c-level business executive with many years of proven track record of building enterprise value and shareholder value. He has successfully started eight technology, industrial and manufacturing enterprises and all have been successfully acquired at premium multiples in the industry. Prior to being a serial entrepreneur he has been employed with leading aerospace, telecom, technology, industrial and supply chain based companies.

Unitron Media

A Public Relations Agency

Mark Gomez

4570 N. First Ave , Suite 120

Tucson, AZ 85718

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Is 3D Printed Titanium Fatally Flawed? here

News-ID: 342396 • Views: …

More Releases from Hasit Vibhakar

Rapid Prototyping and 3D Printing Making a Mark in Dentistry

San Diego, CA - (Open PR - May 24th, 2016) - Like many other branches of medical science, the various forms of additive manufacturing such as rapid prototyping and 3D printing are making a significant position in dentistry. Today, millions of orthodontic braces, dental crowns, bridges, etc. are being made with the help of 3D printing. These are being produced with the help of game changing industrial 3D printers which…

Caterpillar Announces Grand Opening of 3D Printing & Innovation Accelerator.

Mossville, Illinois--(OpenPR – May 10th, 2016) - Global construction firm Caterpillar NYSE: CAT Stock: $CAT has opened a suite of three new innovation spaces at its Global Research & Development Center in Mossville, Illinois. The suite will help to “fuel the future, driving even greater collaboration, innovation and acceleration” within the company.

As the world’s leading manufacturer of construction equipment, Caterpillar provides an incredibly diverse range of products through its global…

Stratasys to release Q1 earnings Week of May 9

TUCSON, AZ--(OpenPR – May 9th, 2016) - 3D printer maker Stratasys (Nasdaq: SSYS) will report its first-quarter results on May 9. The company will post its results before the market open, with analysts expecting a loss of 15 cents per share. During the same period last year the company earned four cents per share, and the stock is down 9.4% on the year.

Technical Analysis

$SSYS was recently trading at $20.58, down…

New Study Shows Manufacturing Demand for Natural Gas Will Grow.

TUCSON, AZ--(OpenPR – May 9th, 2016) - Today, the National Association of Manufacturers (NAM) Center for Manufacturing Research and IHS Economics released a new comprehensive study that reveals how natural gas has strengthened manufacturing and encouraged U.S. manufacturing growth and employment and highlights the positive impact to communities around the United States.

Manufacturers use natural gas for fuel, such as drying, melting, machine drive and space heating, and as a…

More Releases for Titanium

Ferro Titanium Market: Long-Term Value & Growth Seen Ahead | Baosteel, Global Ti …

HTF MI recently introduced Global Ferro Titanium Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status (2024-2032). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence. Some key players from the complete study are AMG Advanced Metallurgical Group, Global Titanium Inc., Mottramite Limited, Des Raj Bansal Group,…

TITANIUM

TITANIUM#1

Unleash the Power: Support the "Titanium" Comic Book on Kickstarter Today!

The world of superheroes is about to get a groundbreaking addition with the launch of the "Titanium" comic book Kickstarter campaign. From the creative minds behind this thrilling new project comes a story that will captivate fans of all ages, blending action, emotion, and a deep dive into the human experience of power and self-doubt.

About Titanium

"Titanium" follows the journey of…

Titanium Ingots Market to Eyewitness Massive Growth by 2029: American Elements, …

Latest Study on Industrial Growth of Global Titanium Ingots Market 2023-2029. A detailed study accumulated to offer the Latest insights about acute features of the Titanium Ingots market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends…

Global Titanium Chloride Market, Global Titanium Chloride Industry, Titanium Chl …

Titanium chloride is also known as titanium tetrachloride, titanium dichloride or titanium trichloride. Titanium chloride is an inorganic compound which is colorless and has an incisive odor. It is a human-made mineral and does not exist naturally in the environment that contains high levels of titanium. It is most significantly used in the chemical industry as an intermediate in the production of titanium metal and titanium dioxide. Due to its…

Global Titanium Sponge for Aerospace & Defense Market 2020 By Segment Forecasts …

The Global Titanium Sponge for Aerospace & Defense Market report by IndustryGrowthInsights.com provides a detailed analysis of the area marketplace expanding; competitive landscape; global, regional, and country-level market size; impact market players; market growth analysis; market share; opportunities analysis; product launches; recent developments; sales analysis; segmentation growth; technological innovations; and value chain optimization. This is a latest report, covering the current COVID-19 impact on the market. The pandemic of Coronavirus…

Titanium Sponge for Aerospace & Defense Market Top Key Players: Zunyi Titanium, …

Global titanium sponge for aerospace & defense market is estimated to exhibit around 4.3% CAGR from 2018 to 2024. Requirement of materials with low weight, high tensile strength, and very high resistance to corrosion for better performance and durability of the airplanes will propel the industry growth. Enhancing the fuel efficiency and aircraft weight reduction is among the key factor for growth of titanium sponge for aerospace & defense market.…