Press release

Online calculation and configuration for pressurised enclosures and cabinets

QUINTEX create the easiest low pressure system application online with innovative solution.• Are overpressure systems difficult?

• To most people project work with overpressure systems take a long time to calculate?

• Engineering time is an expense you can ill afford?

• Ex-Design is only allowed by a specialist?......

Not anymore!

This unique and innovative idea by Quintex GmbH is already established and proven in the market using an easy-to-use overpressure system. Fabrication and assembly is now more efficient, simplified by the ‘release’ operation by a gas detector. No special programming is necessary.

Not only is the final operation simple but the preliminary design and valuation of the system using the Quintex online calculation programme is easy and quick to use.

No sophisticated technology is required using the Quintex program, allowing the parameters to be quickly set which then automatically ‘select’ the required enclosure type and size calculating the price instantly for the created system using standard ‘off-the-shelf’ components and equipment.

Using our calculation programme "Calculation for pressurised enclosures" you can configure a system suitable for operation in an Atex Zone 1 or 2, gas or dust environment certified area by calculation.

Often you may find yourself in a situation where you are required to supply a minimum quantity of assembled units and it is not cost effective or viable to obtain the necessary Atex approval from a certified body. QUINTEX have already paved the way with their SPZ series standard sized enclosures (specific for connections under low pressure) to allow all customers to carry out their own installations and assemblies using an approved over-pressure system that is already approved and certified for use without any necessary flushing phase or pre-set requisites - - simple Plug & Play!

The online configurator is there to assist you with the design and valuation. It is easy and simple to use by entering only 4no. key factors:-

1. Maximum power dissipation of the complete assembly;

2. Maximum required switching capacity;

3. Required supply voltage;

4. Preferred enclosure material.

These self explanatory input fields are entered in a normal manner and by the simple click of a button are then interpreted and calculated with the result appearing in a new programme window. If additional technical details or information is required our team are available to answer your queries via telephone, email or direct online chat.

The quickest and simplest way to build a safe and self-certified system for an Atex specified area using standard non-certified products and equipment.

Quintex GmbH manufactures and supplies material for trace heating (heating tapes, heating cables, controller, connection sets) and explosion protection ( Ex e terminal boxes, pressurized systems, line bushings,own range of local control function, local control stations - all can be specified and ordered online)

Quintex GmbH

i_Park Tauberfranken 13

97922 Lauda-Koenigshofen

http://www.quintex.eu/en/overpressure_calc.html

info@quintex.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Online calculation and configuration for pressurised enclosures and cabinets here

News-ID: 336402 • Views: …

More Releases from Quintex GmbH

Pressurized HMI in Ex Zone 1 at an automotive supplier

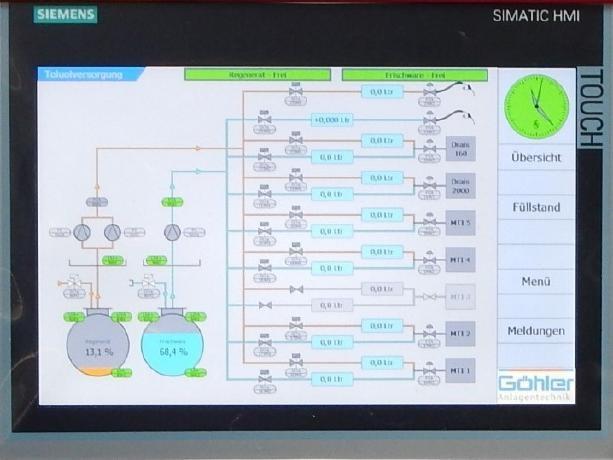

Quintex GmbH was able to win an order with a leading manufacturer and OEM for sealing systems in the automobile industry together with its customer, Göhler Anlagentechnik.

For toluol supply facilities in zone 1, the customer required a system with a zone 2 panel by Siemens. In addition, the costumer required that the touch function of the twelve inch widescreen TFT display be completely retained even under harsh industrial conditions.

Different solutions…

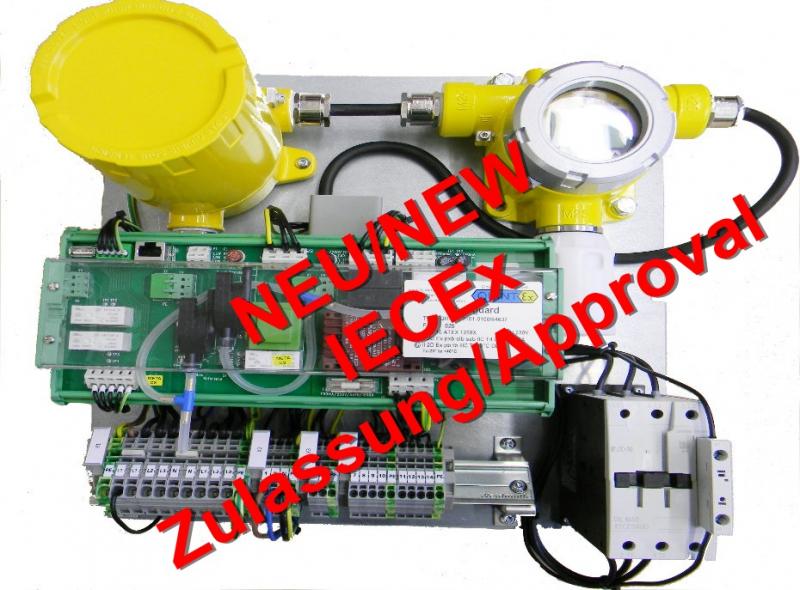

Overpressure system with gas detection for hazardous areas (ATEX/IECEx)

We made a little video to show the ease of use of overpressure system in hazardous areas for un-approved devices. It is the easiest way to bring YOUR device into hazardous area too.

The explosion protection at the "overpressure system 2.0" is realized by operating a non-explosion-protected equipment in a protected enclosure. This housing is protected by a durable pressure with air or an inert gas prior to penetrate the enclosure…

Local Control Functions at a Fuel Loading Area

Ex certified Local control functions you find in many chemical and petrochemical Applications. A typical Application is a switch for Illumination. A big handle is therefore required to make sure that the people can switch on and off the Equipment easily also with gloves.

The requirement is often very different. The showed application is a 2-pole main switch for illumination at a Tank Truck Fuel Loading Area operated by “NIS”…

Electrical equipment in waste water treatment plants

The screen represents the first cleaning stage in a waste water treatment plant after the inlet.

With this mechanical pre-treatment, the waste water is passed through a screen or sieve. Coarse dirt of all kinds, such as stones, branches, leaves, damp toilet paper, sanitary towels and a lot of other debris, get caught there and are removed from the further clarification cycle.

Basically, different types of screens are used. These range from…

More Releases for Overpressure

Busch Vakuumteknikk AS and VakuumConsult AS become Busch Vacuum Solutions Norway …

VakuumConsult AS was founded by Ivar Berg in 1999 and has since then established itself as the dominant company in medium and high vacuum in Norway. The company has been a dealer for Alcatel, which later became Adixen before the company was bought out by Pfeiffer Vacuum. Ivar Berg, and his son Espen, have delivered excellent products and excellent customer service over many years and are recognized names in the…

World-class High Pressure Valve Manufacturer| HiFlux

It operates the manufacture factory in South Korea with the strict standard quality control in accordance with ISO and CE certificate.

The features of the elegant design, easy-to-operation, excellent performance and stability of the HIFLUX products give a great satisfaction to thecustomers over the world.HIFLUX is well known in the industry for a long time to supply the customers with the world-class high-quality products through constant Research&Development.

HIFLUX Safety Valve(Safety Head -…

Ultra-precision Digital Pressure Gauge |DACELL

DACELL Co., Ltd. is manufacturing ultra-precision load cells and various weighing and measuring products based on 40 years of experience in manufacturing of weighing and measuring products and with its own superior technologies, which can be used in various fields of industries.

It exerts every effort to provide customers with total solutions for a field of load cells and as well as advanced weighing and measuring field by developing high-quality products…

Pressurized HMI in Ex Zone 1 at an automotive supplier

Quintex GmbH was able to win an order with a leading manufacturer and OEM for sealing systems in the automobile industry together with its customer, Göhler Anlagentechnik.

For toluol supply facilities in zone 1, the customer required a system with a zone 2 panel by Siemens. In addition, the costumer required that the touch function of the twelve inch widescreen TFT display be completely retained even under harsh industrial conditions.

Different solutions…

Overpressure system with gas detection for hazardous areas (ATEX/IECEx)

We made a little video to show the ease of use of overpressure system in hazardous areas for un-approved devices. It is the easiest way to bring YOUR device into hazardous area too.

The explosion protection at the "overpressure system 2.0" is realized by operating a non-explosion-protected equipment in a protected enclosure. This housing is protected by a durable pressure with air or an inert gas prior to penetrate the enclosure…

Example of standardized overpressure system

This is an example of our space saving and easy to handle overpressure system 2.0. We are working with release by gas detection, so that no volume calculation, flow calculation and programming must be done. A real alternative to large and heavy flame proof cabinets. This is ready to ship and by the weight not too expensive. More about our standardized system you will find here:

https://goo.gl/HPhRf3

Quintex…