Press release

Aluminum Forging Market is Anticipated to Grow at A Sluggish CAGR of 5.8% by 2031- TMR Study

Aluminum forging stands as a pivotal manufacturing process, showcasing the prowess of transforming aluminum into desired shapes through precise heating and force application. This versatile process encompasses varied techniques, including open die forging, closed die forging, and ring rolling, each tailored to produce a spectrum of aluminum-based products.Diverse Techniques in Aluminum Forging

Open die forging, characterized by shaping aluminum through hammering or pressing while maintaining temperatures below the melting point, finds application in crafting simple structures such as bars, rods, or plates, showcasing its versatility and simplicity in production.

Request for a sample of this research report at (Use Corporate Mail Id for Quick Response) - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85581

Industry Dynamics Propelling Market Growth

The aerospace and automotive industries represent the leading consumers of aluminum forging. In the aerospace sector, the application spans across airframe components, landing gears, and engine parts, driven by the industry's pursuit of lightweight components to enhance fuel efficiency.

Similarly, within the automotive sector, aluminum forging plays a pivotal role in manufacturing suspension components, engine parts, and transmission systems, further propelled by the escalating demand for electric and hybrid vehicles.

Impact on Infrastructure Development

The construction sector, another significant end-user, leverages aluminum forging to fabricate building facades, roofing systems, and structural components. The adoption of aluminum forging in construction not only reduces structural weight but also elevates energy efficiency while curbing greenhouse gas emissions.

Aluminum's durability and corrosion resistance make it an ideal choice for structures in coastal and humid environments, a feature distinguishing it from materials prone to corrosion and degradation, such as steel.

Rise of Custom Processes

The trend towards custom processes within the aluminum forging sector showcases prominence, offering heightened flexibility in design, size, and shape. This segment empowers end-users to achieve precise specifications, thereby enhancing the overall quality and performance of their products.

Regional Dynamics and Market Projections

Asia Pacific emerges as a frontrunner in the aluminum forging market, poised to hold the largest share owing to the presence of diverse end-use industries and an escalating demand for lightweight and high-strength materials. The region's surge in infrastructure development, particularly in emerging economies like China and India, propels the need for aluminum in transportation, energy projects, and other construction endeavors.

Moreover, the abundance of skilled labor, competitive pricing, and a robust network of aluminum forging vendors bolster the region's market statistics, further reinforcing Asia Pacific's dominance in the global landscape.

Key Players and Innovations

The industry is witness to robust competition between numerous small to medium-sized aluminum forging companies and established enterprises. These entities heavily invest in research and development endeavors, introducing advanced forging techniques such as isothermal forging and friction stir welding to enhance efficiency and cost-effectiveness.

Buy this Premium Research Report | Immediate Delivery Available at - https://www.transparencymarketresearch.com/checkout.php?rep_id=85581<ype=S

Noteworthy Industry Developments

Recent partnerships and installations reflect the industry's push toward innovation and expansion. Collaborations like the agreement between General Atomics Aeronautical Systems Inc. and Bharat Forge Ltd. to produce landing-gear components highlight efforts to bolster manufacturing prowess. Additionally, installations of high-capacity equipment, such as the 2,500-ton scotch yoke press by Farina at Strojmetal, signify strides in elevating production capabilities.

The aluminum forging market, driven by diverse industries and fueled by technological advancements, showcases robust growth potential. From aerospace to automotive and construction sectors, the versatility and efficiency of aluminum forging stand as a cornerstone in material fabrication. Regional dominance, innovative strides, and collaborations pave the way for an exciting trajectory for this essential manufacturing process.

About Us Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. The firm scrutinizes factors shaping the dynamics of demand in various markets. The insights and perspectives on the markets evaluate opportunities in various segments. The opportunities in the segments based on source, application, demographics, sales channel, and end-use are analysed, which will determine growth in the markets over the next decade.

Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers, made possible by experienced teams of Analysts, Researchers, and Consultants. The proprietary data sources and various tools & techniques we use always reflect the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in all of its business reports.

Contact Us

Nikhil Sawlani

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Forging Market is Anticipated to Grow at A Sluggish CAGR of 5.8% by 2031- TMR Study here

News-ID: 3319819 • Views: …

More Releases from Transparency Market Research

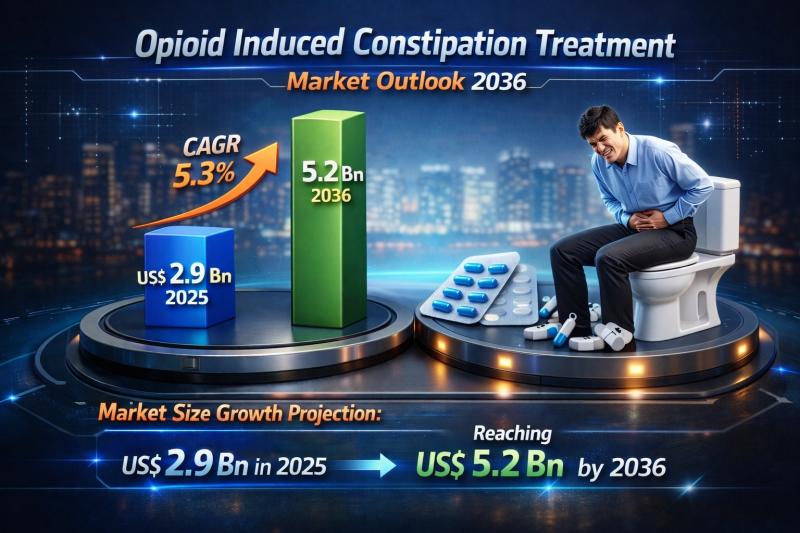

Global Opioid Induced Constipation Treatment Market Set to Reach USD 5.2 Billion …

The global opioid induced constipation (OIC) treatment market is witnessing steady and sustained growth as healthcare systems worldwide place increasing emphasis on comprehensive pain management and supportive care. Valued at US$ 2.9 billion in 2025, the market is projected to reach US$ 5.2 billion by 2036, expanding at a compound annual growth rate (CAGR) of 5.3% from 2026 to 2036. Growth is primarily fueled by the rising prevalence of chronic…

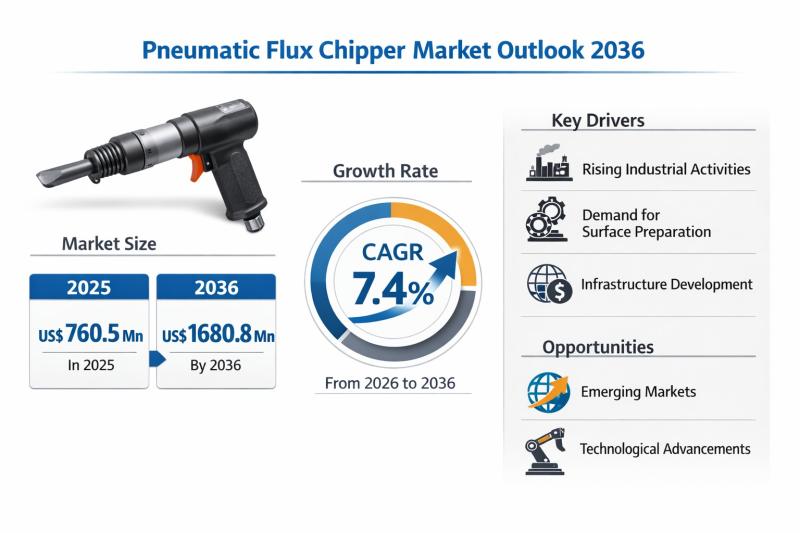

Pneumatic Flux Chipper Market Expanding at 7.4% CAGR Through 2036 - By Product T …

The global Pneumatic Flux Chipper Market is set to witness sustained and resilient growth over the next decade, underpinned by expanding heavy manufacturing activities, rising welding and fabrication demand, and continuous investments in industrial infrastructure across emerging and developed economies. According to the latest industry analysis, the market was valued at US$ 760.5 Mn in 2025 and is projected to reach US$ 1,680.8 Mn by 2036, expanding at a compound…

AI in Automotive Market Outlook 2036: Global Industry to Surge from US$ 19.8 Bil …

The AI in automotive market is entering a phase of exponential expansion, supported by rapid digitization of vehicles, growing safety mandates, and consumer demand for intelligent mobility. The global market was valued at US$ 19.8 Bn in 2025 and is projected to reach US$ 244.4 Bn by 2036, registering a remarkable CAGR of 27% from 2026 to 2036.

This growth trajectory reflects the transition of automobiles from mechanically driven products to…

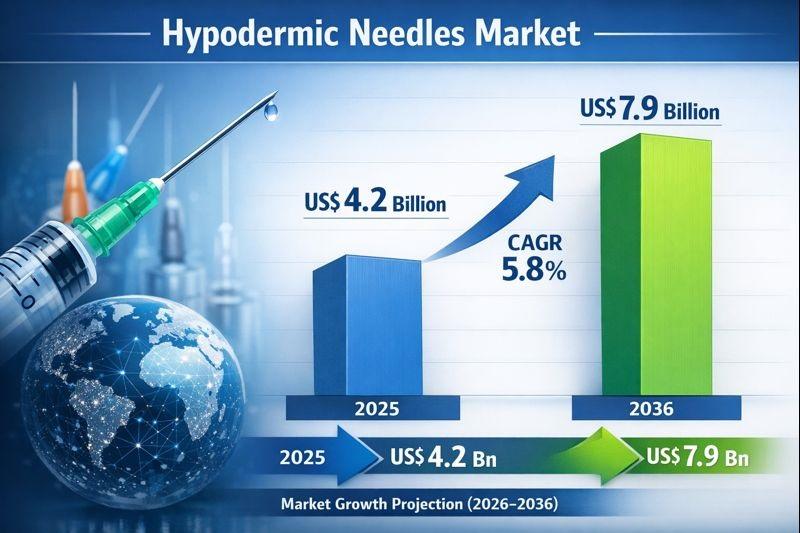

Hypodermic Needles Market to Reach US$ 7.9 Billion by 2036 on Rising Injectable …

The global hypodermic needles market was valued at approximately US$ 4.2 billion in 2025 and is projected to reach around US$ 7.9 billion by 2036, expanding at a CAGR of nearly 5.8% from 2026 to 2036, driven by the rising prevalence of diabetes, cancer, and chronic diseases, growing demand for injectable drugs and biologics, and the expansion of global vaccination and immunization programs; increasing adoption of safety-engineered and disposable needles,…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…