Press release

BINDER presents a global innovation at ACHEMA

At this year's ACHEMA, among the many highlights that BINDER GmbH presented was its thermoelectric cooling incubator with a capacity of 170 liters – an innovation that cannot be found anywhere else in the world. The innovative products and technologies attracted industry professionals from a whole range of sectors to the BINDER stand at the trade fair.Between June 15 and 19, ACHEMA 2015 – the leading international trade fair for the process industry – provided the venue for BINDER GmbH to showcase its products under the motto "Evolution in Simulation Technology – Best Conditions for Your Success". The Tuttlingen-based family company is the world's leading specialist in simulation chambers for scientific and industrial laboratories. BINDER presented new products and pioneering technologies to industry professionals and, for the first time the specialist are venturing with the KBF 1020 constant climate chamber into the new market territory of machines with capacities of over 1000 liters. The large-volume model of the tried-and-tested KBF series is featuring 1,020 liters of usable space. The cube-shaped interior is exceptionally roomy and allows large samples to be stored efficiently. Particularly where the pharmaceutical industry is concerned, it offers clear advantages for carrying out stability tests. As further highlight of the event, exhibited its thermoelectric cooling incubator with an interior volume of 170 liters – a product that cannot be found anywhere else in the world. The fully-fledged table unit provides ample space with a user-friendly depth and is significantly quieter than a comparable compressor unit. Thanks to new stacking options, the cooling incubator is ideally suited to mixed stacking with its smaller sibling, the KT 115, making it extremely flexible to use. A new size has also been introduced for the C series of CO2 incubators: In the future, the standard model for cell cultivation is to be available with an expanded interior volume of 170 liters. Up against its 180°C hot air sterilization, potential sources of contamination do not stand a chance.

The new preheating chamber technology developed by BINDER ensures reliable, reproducible incubation conditions. This enables homogeneous temperature distribution thanks to a horizontal airflow on both sides, even when fully loaded. These were benefits that were clear to see for visitors to the BINDER trade fair stand. The units are supplemented by a new, state-of-the-art controller featuring an LCD display, which enables intuitive operation. A team of experts at the stand provided information on the use and function of the different units. They are designed to suit all kinds of applications in the laboratory or in the process industry, and can be used in stress tests of any type. BINDER had even prepared refreshments to help hot and bothered visitors cool down amidst the hustle and bustle of the trade fair – ice cream creations offering an indulgent treat.

More information is available at: www.binder-world.com

BINDER is the world's largest specialist in simulation chambers for the scientific and industrial laboratory. With its technical solutions, the company contributes significantly to improving the health and safety of people. Our range of products is well-suited for routine applications, highly specialized work in research and development, production and quality assurance. With approx. 400 employees worldwide and an export quota of 80%, BINDER 2013 sales were more than 60 million euros.

BINDER GmbH

Dorothea Fichter-Fechner

Im Mittleren Ösch 5

78532 Tuttlingen

Tel.: +49(0)7462-2005-632

Dorothea.Fichter-Fechner@binder-world.com

www.binder-world.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release BINDER presents a global innovation at ACHEMA here

News-ID: 311872 • Views: …

More Releases from BINDER GmbH

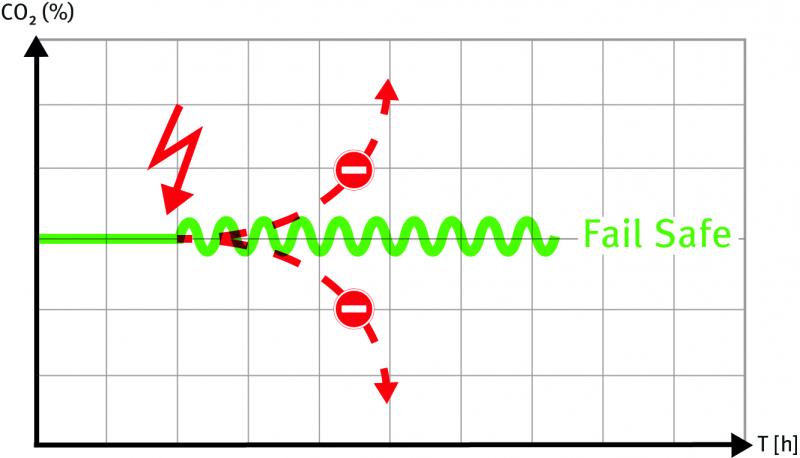

A new innovation from BINDER: The fail-safe function

BINDER incubators are the best on the market. Why is this? There is a simple answer in the first instance: Because they are constructed in as straightforward a way as possible, they are incredibly reliable.

The risk of the cultures inside a BINDER incubator becoming contaminated is reduced to a minimum.

But BINDER customers have high standards and want to know more about the details. This is exactly where the…

In safe hands with the GLP checklist

The "Good Laboratory Practice" regulatory mandate (GLP for short) was introduced in 1978 after the FDA (U.S. Food and Drug Administration) had already identified significant deficiencies in toxicological studies in the years preceding. The German Chemicals Act was introduced in an effort to ensure that newly approved drugs for human consumption really are safe and minimize any and all risks.

The values of transparency, traceability, assignment of responsibilities, and safekeeping are…

More Releases for ACHEMA

MB Bäuerle presents a global novelty at the Achema

At the Achema fair that will be held in Frankfurt / Germany from June 15 until June 19, the folding machine manufacturer MB Bäuerle will show for the first time two versions of its fold module for producing package inserts for the pharmaceutical, cosmetics and packaging industry (Hall 3.1, Stand A11). Both fold units are available for integration into cartoning and packaging machines and as stand-alone folding systems.

The leafletFOLDER…

Gallery „The Art of Filtration“ at Achema 2012

At Achema from June, 18-22, 2012 Hahnemühle FineArt GmbH introduces visitors its gallery "The Art of Filtration".

Large images of artist, Ralf Lürig, demonstrate the fascinating application areas of filtration products.

Visitors plunge in to the multifaceted world of filtration.

Papers whirl in the air next to sprouting seeds on a paper accordion, is one part of an image.

Next to painted pictures, technical drawings represent bespoke product manufacture. Artist Andreas Kulpe integrates paper…

GEA Diessel at ACHEMA

GEA Diessel will be fully represented at ACHEMA 2012 in Frankfurt from 18-22 June with the latest technology for pharmaceutical fermentation, food and beverage technology as well as metering systems on show.

Pharmaceutical fermentation

GEA Diessel fermentation systems are recognised worldwide to be of the highest quality. This quality is illustrated by their customised design, free from dead legs making them ideal for sterile operation; and the accuracy of the…

GEA Niro drying technology at ACHEMA 2012

At ACHEMA (June 18-22 June, Frankfurt, Germany), GEA Process Engineering - the company behind the world-recognised GEA Niro spray and fluid bed drying technologies – will be present to promote GEA Niro drying systems and discuss how working with GEA helps customers meet the strictest requirements to product quality, plant efficiency and safety, and sustainable production.

The company will be showing some of its small-scale units at the booth including:…

ACHEMA 2012: Getting ready for the energy turnaround

„Innovative Energy Carriers and Storage“ on display at ACHEMA’s Special Show:

Renewable energy generation and mobile applications depend on innovative technologies for energy storage. The ACHEMA Special Show 2012 presents the latest technological trends and concepts. In combination with the scientific congress and closely interlinked with the whole range of process technologies on display, it offers a unique setting for the discussion of integrated and innovative solutions.

It’s not just that…

SIGMA at ACHEMA 2009

Unna, Germany, May 2009 - SIGMA Ingenieurgesellschaft was represented in partnership with ITandfactory GmbH (CADISON) at the ACHEMA 2009 exhibition in Frankfurt/Germany.

We say thank you to all program users and prospective customers visiting our stand at the ACHEMA 2009.

The ACHEMA as one of the leading trade fairs worldwide offers great opportunities for the presentation of our software products to the qualified audience: ROHR2 for pipe stress analysis and SINETZ for…