Press release

Material-saving Cutting and Treatment of Metal Tubes

Berg/Germany, 18. 6. 2014Metal tubes – from aluminum to titanium – are essential elements of many products. Consequently a material-saving and exact cutting of the basic material material combined with a directly linked further treatment results in cost savings and thus an increase of earnings.

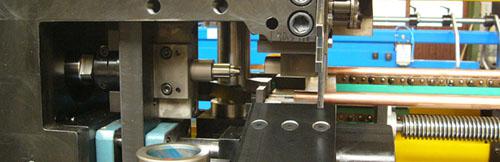

Basing on own patents the chipless and low-burr cutting system of Weerth Handling Systeme Gmbh, Berg/Germany, including the special ‚tear-break‘-system, built-up its national and international reputation during the last 25 years.

Satisfied clients from BMW (automotive) to Zehnder (heating systems), i. e. from automotive applications to solar appliances profit from the system. Further references are available from www.weerth.com/en/.

The advantages ?

The tubes – whether from coils or standard rods – are straightened and (nearly without any loss, due to the chipless cutting/tear-break system) cut to exact lengths. If needed a following storage system can take up the resulting pieces and supply them again to the appropriate following stages of the production line. Cycle times of up to 1.900/hour can be reached, depending on the respective task. The wear of the cutting knives is only minor and they can reach up to 80.000 cuts.

The material-saving is quite remarkable: With an average loss, using a conventional cutting saw, of about 1,5 mm/cut and just 40.000 cuts this results in abt. 60 m raw material – these are now saved and thus your profit increases. Depending on the starting material the amortization of a respective machine/plant is reached quite quickly.

A further advantage result out of the fact that no additional washing/cleaning or expansion of the cut tubes is necessary, e. g. for inserting a mandrel for further treatment. Thus here is another reason for the cost-effectiveness of the Weerth machines/plants.

Questions are answered via the website www.weerth.com/en and/or directly from the specialists of the company.

Author:

Michael Richter – International Marketing- and sales consultant – concentrates for more than 40 years on strategic marketing planning as well as marketing and selling of investment goods and long-lasting consumer goods in/to all 5 continents.

Starting his business as an independent marketing consultant, in 1991, especially for SMEs worldwide, he offers his knowledge and experience to his worldwide clientele.

In addition he holds national and international, internal and external lectures on international marketing matters – especially in/for the European Union.

Michael Richter – International marketing and sales consultant

Hauptstrasse 27

88422 Seekirch/Germany

Marketing: http://www.marketing-und-vertrieb-international.com/en/

Country experience: http://www.internationales-marketingkonzept.de/en/

michael.richter@marketing-und-vertrieb-international.de

Phone: +49-7582-933371

Weerth-Company description

WHS is one of the first manufacturers worldwide, producing innovative machinery and plant for the chipless and low-burr-cutting of metal tubes, including the self-developed, patented, tear/break-system. WHS is a German company, producing machinery the cutting knife of which can cut up to 80.000 times (depending on the pre-product), which - together with the minimum material loss during cutting - leads to significant cost savings resp. profit increases.

Weerth-Handling-Systeme GmbH

Hans Ernst Weerth

Bachstrasse 10

88276 Berg-Weiler/Germany

+49(0)751-362993-0

+49(0)751-362993-22

http://www.weerth.com

info@weerth.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Material-saving Cutting and Treatment of Metal Tubes here

News-ID: 290035 • Views: …

More Releases from Michael Richter - International marketing and sales consultant

Economic Cutting of Metal Tubes – from Aluminium to Titan

Berg/Germany, 11-26-2014

Without metal tubes cut to a specified length – out of various metallic materials – many products cannot fulfil their proper functions. Thus an optimized and economic handling of the tubes before and during the cutting process is particularly important.

The German company Weerth Handling Systeme GmbH, Berg/Baden-Württember, has specialised from its foundation in 1986 on the chipless cutting and machined end conditioning of all kinds…

Metal tubes: Handling and Processing by Systems of Weerth Handling-Systeme GmbH

Seekirch 11.2.2014

Update: Many industries need metal tubes cut to exact lengths (millimeters) for their products - out of many metals and alloys. Especially adapted and extremely economical working systems are supplied by Weerth Handling Systeme (WHS), Germany/Baden-Württemberg. The system advantages are considerable.

WHS is one of the first manufacturers worldwide, producing innovative machinery and plant for the chipless and low-burr-cutting of metal tubes, including the self-developed, patented, tear/break-system. WHS is a…

More Releases for Weerth

Economic Cutting of Metal Tubes – from Aluminium to Titan

Berg/Germany, 11-26-2014

Without metal tubes cut to a specified length – out of various metallic materials – many products cannot fulfil their proper functions. Thus an optimized and economic handling of the tubes before and during the cutting process is particularly important.

The German company Weerth Handling Systeme GmbH, Berg/Baden-Württember, has specialised from its foundation in 1986 on the chipless cutting and machined end conditioning of all kinds…

Metal tubes: Handling and Processing by Systems of Weerth Handling-Systeme GmbH

Seekirch 11.2.2014

Update: Many industries need metal tubes cut to exact lengths (millimeters) for their products - out of many metals and alloys. Especially adapted and extremely economical working systems are supplied by Weerth Handling Systeme (WHS), Germany/Baden-Württemberg. The system advantages are considerable.

WHS is one of the first manufacturers worldwide, producing innovative machinery and plant for the chipless and low-burr-cutting of metal tubes, including the self-developed, patented, tear/break-system. WHS is a…

Fast – Clean – Economical: Cutting metal tubes – from steel to titanium, u …

Seekirch, October 12, 2012

Metal tubes – out of various materials – are absolutely necessary in many modern products, despite numerous substitutions. Therefore it is wise to treat them material friendly as well as to minimize material loss in cutting processes..

Weerth-Handling-Systeme GmbH, Berg/Germany, have specialized in cutting and end forming of metal tubes up to a diameter of 76 mm, as well as in storing and feeding tubes for a…

Industrial tube and pipe processing – new website

Whatever the technical progress is: Without tubes and pipes of various metals and alloys a multitude of products is nearly unthinkable – from radiators, to cars or refrigerators, various machinery, solar plants, and more …

This is the speciality – for more than 20 years now – of Weerth-Handling-Systeme, Berg/Germany, one of the typical European ingenious SME’s.

The machinery developed and produced by Weerth – from the automatic or manual tube…