Press release

Withstanding Extreme Conditions - Stauff Clamps meet the requirements of Russian Railways

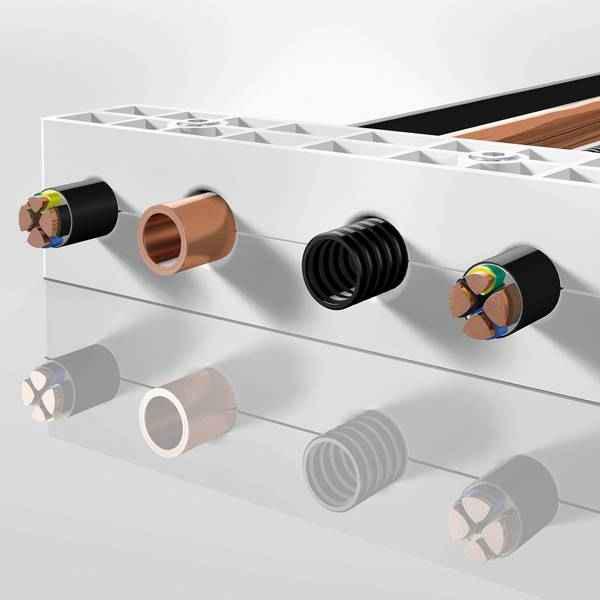

The Stauff Group have been suppliers to the rail industry for almost 35 years, the first project starting in the 1970s with Stauff UK supplying clamping components and systems to the Metropolitan Cammell Carriage and Wagon Company (MCCW), a former Birmingham, England based manufacturer of railway carriages and wagons. Original STAUFF clamps were used for trains on the Jubilee Line of London's underground railway system, which was officially opened on 30 April 1979, with passenger services operating from 1 May 1979.Over the years, Stauff’s specialist clamp development and manufacturing capabilities have enabled the company to accommodate the increasing safety demands of the global rail industry, with a range of clamp body materials meeting all commonly used international fire protection and safety standards and regulations. All available STAUFF clamp body materials are capable of being moulded to any configuration, providing an industry solution for all pipe, tube, hose and cable support requirements, for both manufacturers and sub-contractors.

In February 2013, Stauff clamp bodies made of SAV0, a thermoplastic elastomer with V0 classified fire-protection capabilities according to UL 94 plastics flammability standard released by Underwriters Laboratories, were successfully tested in the Test Center for Railway Transport Vehicles in the Russian Federation.

The testing procedures included the inspection of clamping / holding forces of SAV0 clamp bodies of the Standard Series according to DIN 3015 - properly assembled with metal mounting hardware such as elongated weld plates, hexagon head bolts and cover plates - under the influence of mechanical and climatic factors. These were namely the exposure to vibration at regular and extreme ambient temperatures down to minus 55 degrees Celsius. All tests were performed according to GOST state standards 15150-69 and 30631-99.

In conclusion, no sliding or movement of pipelines related to their original position could be observed, and the clamp bodies maintained their full elasticity, which is an important contribution to efficient noise reduction and vibration damping in industrial applications.

The test results above have provided Stauff with the final technical approval to supply SAV0 clamp bodies and metal mounting hardware for the Desiro RUS project, an electric multiple unit passenger train developed by Siemens AG for Russian Railways (RŽD), which branded them Lastochka (Russian for "Little Swallow").

In mid-2013, a joint venture of Russian Sinara Group and German Siemens AG named Ural Locomotives has commenced production of a second batch of Lastochka trains at the Ural railway engineering plant located in Yekaterinburg, after the Siemens plant in Krefeld, Germany had fulfilled Russian Railways' initial orders for 54 of these units since April 2011.

While the first batch of trains had to be designed to be fully operational at ambient temperatures as low as minus 40 degrees Celsius for use in the Western / European part of the Russian Federation, the requirements for the trains built in Yekaterinburg were even higher: All components have to withstand extreme ambient temperatures down to minus 55 degrees Celsius while maintaining their original performance properties.

According to the contracts signed in 2011, 6 trains of the new Lastochka series manufactured at the Ural plant are scheduled to be supplied to RŽD by 2014, and another 30 trains by 2015. Overall, the contracts include the delivery of up to 1.200 passenger cars during the period from 2015 to 2020.

About STAUFF

Walter Stauffenberg GmbH & Co. KG was founded in the 1950s in Werdohl, in the German province of North Rhine-Westphalia, and was initially a contract turning shop. Today the company operates under the trade name STAUFF, developing, producing and marketing fluid technology components for use in plant construction and mechanical engineering. In the fields of tube, pipe and hose clamps, measuring technology and hydraulic filtration, STAUFF is one of the world’s leading organisations in a growing industrial segment.

Meanwhile, more than 1200 employees (12/2012) in 18 companies generate an annual turnover of more than EUR 190 million (12/2012) worldwide. Additional distribution subsidiaries have recently been opened in Ireland, Malaysia and Vietnam. Besides the group headquarters in Werdohl Ehrenfeld, the company has production and logistics facilities in the German cities of Plettenberg-Ohle and Neuenrade-Küntrop.

Walter Stauffenberg GmbH & Co. KG

P.O. Box 1745

58777 Werdohl

Im Ehrenfeld 4

58791 Werdohl

Germany

Mr Boris Mette

Public Relations / Marketing

E-Mail: b.mette@stauff.com

Tel.: +49 (0) 2392/ 916 154

Fax: +49 (0) 2392/ 916 270 154

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Withstanding Extreme Conditions - Stauff Clamps meet the requirements of Russian Railways here

News-ID: 272188 • Views: …

More Releases for Stauff

Stauff expands weld fittings range

New model series for demanding applications, e.g. in power plants

With the series FI-SNR and FI-ASV, Stauff expands the product range of Stauff Connect weld fittings. This connection technology is being replaced increasingly by easy-to-install forming systems, e.g. Stauff Form, in various applications. But it will still retain its place in the market in the future, especially in the demanding heavy industry and in power plant engineering.

As a full-range provider in…

Stauff expands manufacturing capacities at Werdohl

Investment in high-capacity rotary transfer machines

At its main base in Werdohl, Stauff has placed into service a rotary transfer machine for tube connectors with which some 1.5 million angle, T-connector and cross-pieces can be made from forging blanks.

In this way, the all-in supplier of hydraulic lines has reacted to the considerable demand for its own “Stauff Connect” tube connector range which came onto the market in 2015. A second rotary…

Indestructible: Stauff and Voswinkel components in agriculture

Superior resistance to aggressive substances

The use of components in agricultural machinery places high demands on the corrosion resistance of hydraulic line components, such as tube and hose connections and fasteners. They are not just exposed to usual weather and climate-related hazards, but frequently come into contact with particularly aggressive substances: with fertilizers containing phosphate or nitrogen, pesticides, cleaning concentrates, oils and other media.

Stauff, one of the leading manufacturers of…

The new Stauff Catalogue App

Always at hand: Up-to-date and complete information on Stauff and Voswinkel products

On more than 1,700 pages in total, the 10 individual Stauff product catalogues provide all information about the 40,000 standard articles of the company, that are considered to be relevant and of particular interest for design engineers as well technical purchasers of pipework components and hydraulic accessories when comparing and selecting products: Product characteristics and features, dimensions, material information,…

Voswinkel becomes part of the Stauff Group

(Meinerzhagen / Werdohl, Germany) As mutually announced by both companies, the Stauff Group has successfully completed the acquisition of the Meinerzhagen, Germany based company Voswinkel from the Voswinkel shareholder family in April this year already.

With corporate headquarters in Werdohl, Germany and two additional plants in Plettenberg-Ohle and Neuenrade-Küntrop, the Stauff Group develops, manufactures and distributes pipework equipment and hydraulic components for mechanical and plant construction as well as for…

Updated Stauff One product catalogue available

Updated Stauff One product catalogue available

Pipework components, test equipment and hydraulic accessories from a single source

Beginning in February 2014, the new, revised and in some areas significantly expanded general product catalogue will be available from Stauff, the Werdohl, Germany based fluid technology specialist.

On a total of 682 pages, the so-called Stauff One – initially released in spring 2011 – provides all relevant general, ordering and technical information about the company’s…