Press release

New Micro Drill from Intertronics for pcb rework

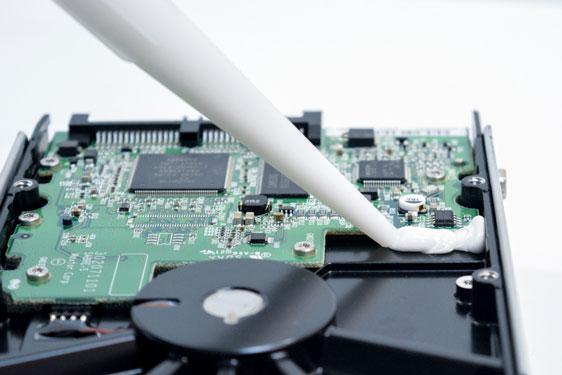

The new CircuitMedic Micro Drill system from Intertronics is versatile and powerful – making it ideal for milling, drilling, grinding, cutting and sanding circuit boards. It removes coating, cuts circuits, cuts leads, drills holes, cuts slots, shapes FR4 and performs many other procedures using various interchangeable bits.Peter Swanson, Managing Director at Intertronics is enthusiastic. “This is a great little tool.” he explained. “It is made to dental quality for delicate board work; it is light and easy to use and comes with a quick change chuck for easy replacement of the various ball mills, abrasive bits and cutting discs which come along in the kit.” Swanson continued, “This means that coatings can be quickly removed, fine holes drilled for epoxy repair of blisters and many other pcb repair tasks carried out with precision and speed.”

Unlike most hand-held tools, the Micro Drill features a tiny, high speed DC motor in the hand piece, eliminating bothersome drive cables and giving the technician better control. A separate power supply keeps the hand piece lightweight and reduces fatigue. Power is supplied by a panel switch or foot switch for ease of use. For further information please see www.intertronics.co.uk/microdrill or visit their blog at www.adhere.uk.com – also see www.youtube.com/intertronicsadhere.

"adhere” from INTERTRONICS - dedicated to providing quality adhesive solutions to high technology, high performance assembly industries, incorporating outstanding levels of technical support and customer service.

The adhere concept covers our range of adhesives, encapsulants, coatings, sealants and tapes as well as the associated dispensing, curing and surface preparation equipment and materials used in the manufacturing and assembly processes. Also our Opti-tec brand of adhesives.

Intertronics have been certified to ISO 9001:2008 standard demonstrating their commitment to customer service and quality in delivery. Certification proves that the Intertronics quality management system ensures consistency and a continuous improvement ethic, leading to high levels of performance and customer satisfaction.

Sales partners include: Araldite, Thinky, Fisnar, DYMAX, Plato, Practical Components, Sipel, Techspray, 3DT Corona Treating Systems, SolderQuick, preeflow, Polytec PT, Opti-tec, Circuit Medic and ACC Silicones.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire, OX5 1JD

Tel: 01865 842842

e-mail: info@intertronics.co.uk

Contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release New Micro Drill from Intertronics for pcb rework here

News-ID: 252195 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for Micro

Micro Injection Molded Plastic Market worth $1,692 million by 2026 | Key players …

According to recent market research "Micro Injection Molded Plastic Market by Material Type (Liquid-Crystal Polymer (LCP), Polyether (PEEK), Polycarbonate (PC), Polyethylene (PE), Polyoxymethylene (POM)), Application and Region - Global Forecast to 2026", published by MarketsandMarkets, the micro injection molded plastic market is projected to reach USD 1,692 million by 2026, at a CAGR of 11.2% from USD 995 million in 2021.

Browse 193 market data Tables and 61 Figures spread through…

Micro Combined Heat & Power (Micro CHP) Market 2022 | Detailed Report

The Micro Combined Heat & Power (Micro CHP) research report combines vital data incorporating the competitive landscape, global, regional, and country-specific market size, market growth analysis, market share, recent developments, and market growth in segmentation. Furthermore, the Micro Combined Heat & Power (Micro CHP) research report offers information and thoughtful facts like share, revenue, historical data, and global market share. It also highlights vital aspects like opportunities, driving, product scope,…

Micro-Invasive Glaucoma Implants Micro-Invasive Glaucoma Implants

Global Micro-Invasive Glaucoma Implants Market Definition: Micro-invasive glaucoma implants is performed for the treatment of the open- angle glaucoma and is done through an ab- interno approach. It is very safe and provides faster recovery as compared to the traditional methods. They usually lower the intraocular by increasing the flow or reducing the production of the aqueous humor. Increasing cases of the glaucoma worldwide is the major factor fueling the…

Global Micro Electric Automotive (Micro EVs) Market Growth 2019-2024

Market Research Report Store offers a latest published report on Micro Electric Automotive (Micro EVs) Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Micro Electric Automotive (Micro EVs) market will register a 5.5% CAGR in terms of revenue, the global market size will reach US$ 9062.2 million by 2024, from…

Global Micro Welding Equipments Market- Growing Popularity and Emerging Trends i …

Welding is a fusion of the two workpieces of the surface to form one, is a precise, reliable, cost-effective and high tech method for joining material. Micro welding is a process that is specifically designed for the welding of small often delicate components. It is also known as precision welding. The process sets up the weld by depositing fine blobs of weld to the components to be fused. The process…

Comprehensive Analysis On Micro Welding Equipment Market 2019 : Pro-Fusion, OR L …

Up Market Research added a new Micro Welding Equipment Market research report for the period of 2019 – 2026. Report focuses on the major drivers and restraints providing analysis of the market share, segmentation, revenue forecasts and geographic regions of the market.

Get Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/108038

The report contains 112 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing…