Press release

Application-oriented research boosts drive technology: A motor of progress

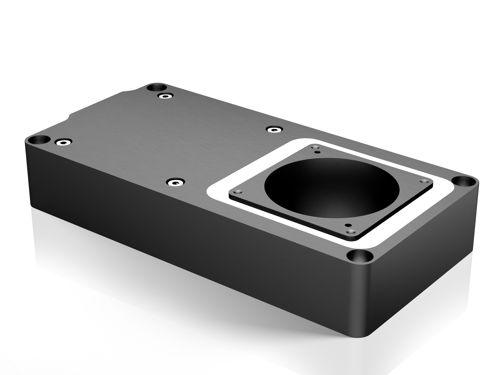

In the coming years, sectors such as the semiconductor industry, life sciences or biotechnology will continue to grow. Increasing requirements in these sectors often affect supporting technologies. A typical example of this is found in drive technology: Inspection and manufacturing systems in the semiconductor industry, for example, normally use air-bearing technology and magnetic linear motors. However, the requirements for precision will continue to increase up into the nanometer range. Such systems also reach their limits when applications require work in a vacuum or nitrogen atmosphere. This issue has now been taken up by drive specialists, who have already achieved promising results with a new electromagnetic nanopositioning system.When a feeling for markets, competence and teamwork ability come together, the user profits in the end. This is currently being proven by a cooperation of the Karlsruhe-based nanopositioning systems market leader PI (Physik Instrumente) (cf. text box 1), the IMMS (Institut für Mikroelektronik- und Mechatronik-Systeme) and the Department of Mechatronics of Ilmenau University of Technology. The result of their collaboration is a novel nanopositioning system based on the principle of magnetic levitation (figure). The platform levitates on a magnetic field that is generated by six coils and is actively monitored via a 6-D sensor. The magnetic field functions as drive and actively guides the platform. The drive and the compact high-resolution measurement system for the six degrees of freedom was developed so that the platform remains passive, in other words no cable connections are necessary. A two-dimensional, optically incremental measurement system records the position with capacitive sensors and serves to control the drive in all axes. In this way, objects can be moved linearly or rotationally on a plane with a pre-viously unattained guiding accuracy. "The current, already quite advanced development study ‘PIMag 6D’ positions with a resolution of 10 nm," Dr. Rainer Gloess, Head of Advanced Mechatronics at PI, is happy to announce. "If the system moves on a circular path with a diameter of 100 nm, for example, the maximum deviation from the ideal path is only a few nanometers."

The prototype currently has a motion range of 100 x 100 x 0.15 mm³. Trajectory motions can be carried out at an acceleration of up to 2 m/s2 and a velocity currently of up to 100 mm/s with nanometer precision. The digital motion controller, based on a modular system from PI, can process different geometry files as well as coordinate transformations and offers an optimum basis for a successful new product line.

Physik Instrumente (PI) in Brief

Over the last four decades, PI (Physik Instrumente) with headquarters in Karlsruhe has developed into the leading manufacturer of nanopositioning technology. The privately managed company with more than 700 employees world-wide is able to fulfill almost any request in the field of innovative precision positioning technology. All key technologies are developed in-house. This means that every phase from design right down to shipment can be controlled: precision mechanics and electronics as well as position sensors and piezo ceramics or piezo actuators. The latter are manufactured by the subsidiary PI Ceramic in Lederhose, one of the global leaders for piezo actuator and piezo sensor products. miCos GmbH in Eschbach near Freiburg, Germany, now is part of the PI group as PI miCos. Its broad product range focusses on flexible positioning systems for ultrahigh vacuum applications as well as parallel-kinematic positioning systems with six degrees of freedom or cus-tomized designs.

The IMMS in Brief

The IMMS (Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH) is a state-owned out-of-university Institute of the Free State Thuringia. It supports small and medium-sized companies in the field of application-oriented preparatory research for the development of products of microelectronics and system engineering. The IMMS, for example, has been developing drive solutions for air-bearing precision motion systems for 15 years. These systems are primarily used in machines for laser structuring, e.g. in precision engineering, medical technology and the laser dicing of wafers.

Kathrin Mössinger

Marketing Coordinator

Phone +49 721 4846-1810

Fax +49 721 4846-1019

k.moessinger@pi.ws

Physik Instrumente (PI)

GmbH & Co. KG

Auf der Roemerstrasse 1

76228 Karlsruhe

Germany

www.pi.ws

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Application-oriented research boosts drive technology: A motor of progress here

News-ID: 252180 • Views: …

More Releases from Physik Instrumente (PI) GmbH & Co. KG

New piezo nanopositioning system: versatile, fast and compact with large clear a …

Large clear aperture, high control dynamics, fast settling times and compact dimensions: PI launches a new product line of linear nanopositioning systems for a broad range of applications. The P-630 stages are perfectly suited, e.g. for use in sensor heads or precision motion of objects in optical and tactile metrology as well as for microstructuring.

With travel ranges up to 80 µm and a direct piezo actuator drive, the compact positioning…

2 mm Travel Range - 20 Milliseconds Settling Time: New Objective Scanner with Pi …

New microscopy methods, such as two-photon microscopy, make it possible to record 3D stacks with up to 1 mm depth in biological samples. For this they require high-performance drives for positioning the objectives.

PI (Physik Instrumente) now developed the new N-725 PIFOC® objective scanner with piezo stepping drives especially for position-ing microscopy objectives. The N-725 provides travel ranges of up to 2 mm along the optical axis. At the same time…

New Version of M-663 Micropositioning Stage: Benefits of PILine® Drive Technolo …

Cost-effective with 2 µm step size. PI (Physik Instrumente) completes its product line of high-velocity M-663 micropositioning stages.

The new linear stage version M-663.5U is especially suited for positioning tasks in automation where a resolution of 0.6 µm and a step size of 2 µm are sufficient. The integrated PILine® linear motor provides push forces to 5 N and a maximum velocity of up to 250 mm/s over a 18 mm…