Press release

Fast – Clean – Economical: Cutting metal tubes – from steel to titanium, up to 76 mm diameter

Seekirch, October 12, 2012Metal tubes – out of various materials – are absolutely necessary in many modern products, despite numerous substitutions. Therefore it is wise to treat them material friendly as well as to minimize material loss in cutting processes..

Weerth-Handling-Systeme GmbH, Berg/Germany, have specialized in cutting and end forming of metal tubes up to a diameter of 76 mm, as well as in storing and feeding tubes for a multitude of production processes.

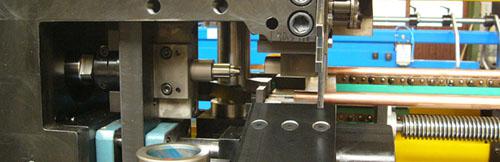

Basing on the ‚orbital cutting process‘ of tubes (chipless and with nearly no burrs) Weerth developed a range of machines and plants – Keywords: ‘Cut-, tear and brake process’.

From manual machines for smaller quantities, to machinery to be integrated into complete production lines, all solutions are adapted to the needs of the respective clients.

After cutting or end forming the tubes can be stored via a thoroughly developed feeder/storage system (originally patented 1992 under EP0348763 and later be automatically fed into a defined production step.

The available systems care especially for maximum material savings as the loss of material (as it occurs e. g. with traditional metal sawing), practically doesn’t exist and thus even additional production steps as washing or deburring can be dropped completely.

The individual cut (of up to 1900 parts/hour) is absolutely clean and the minimal material reduction after cutting does not prevent the insertion of a mandrel.- without additional working step.

Continuous improvements lead to a ‚permanent innovation‘ and advancement of the systems.

World-famous companies – please see the reference list at weerth.com – trust in the well-engineered solutions of Weerth, as well in Germany as also in their international subsidiaries.

Besides of the classical cutting of metal tubes for the automotive industry, heating/ventilating/air-conditioning industries, the solar industry and others, many additional fields of application are conceivable, such as e. g. battery clamps, or hydraulic tubes.

Manufacturer:

Weerth-Handling-Systeme GmbH

Bachstrasse 10

88276 Berg-Weiler/Germany

http://www.weerth.com

info@weerth.com

Tel.: 0751-3629930

-------------------

Michael Richter - International Marketing- and sales consultant - concentrates for more than 35 years on strategic marketing planning as well as marketing and selling of investment goods and long-lasting consumer goods in/to all 5 continents.

He offers this knowledge and experience to his worldwide clientele. In 1991 he started his work as an independent marketing consultant, especially for SMEs worldwide. In addition he holds national and international, internal and external lectures on international marketing matters - especially in/for the European Union.

Michael Richter - International marketing and sales consultant

Hauptstrasse 27

88422 Seekirch/Germany

Marketing: http://www.marketing-und-vertrieb-international.com/en/

Country experience: http://www.internationales-marketingkonzept.de/en/

michael.richter@marketing-und-vertrieb-international.de

Phone: +49-7582-933371

We specialize in machinery and equipment for

- the chipless cutting of steel tubes, pipes out of high-grade steel and alloy metals (with extremely little burrs)

whether straight, curved or from the coil

- trimming of curved tubes and pipes

- the conditioning of tube ends and

- the automatic storage and supply of tubes and rods to the production lines

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fast – Clean – Economical: Cutting metal tubes – from steel to titanium, up to 76 mm diameter here

News-ID: 239561 • Views: …

More Releases from Michael Richter - International marketing and sales consultant

Economic Cutting of Metal Tubes – from Aluminium to Titan

Berg/Germany, 11-26-2014

Without metal tubes cut to a specified length – out of various metallic materials – many products cannot fulfil their proper functions. Thus an optimized and economic handling of the tubes before and during the cutting process is particularly important.

The German company Weerth Handling Systeme GmbH, Berg/Baden-Württember, has specialised from its foundation in 1986 on the chipless cutting and machined end conditioning of all kinds…

Material-saving Cutting and Treatment of Metal Tubes

Berg/Germany, 18. 6. 2014

Metal tubes – from aluminum to titanium – are essential elements of many products. Consequently a material-saving and exact cutting of the basic material material combined with a directly linked further treatment results in cost savings and thus an increase of earnings.

Basing on own patents the chipless and low-burr cutting system of Weerth Handling Systeme Gmbh, Berg/Germany, including the special ‚tear-break‘-system, built-up its national…

Metal tubes: Handling and Processing by Systems of Weerth Handling-Systeme GmbH

Seekirch 11.2.2014

Update: Many industries need metal tubes cut to exact lengths (millimeters) for their products - out of many metals and alloys. Especially adapted and extremely economical working systems are supplied by Weerth Handling Systeme (WHS), Germany/Baden-Württemberg. The system advantages are considerable.

WHS is one of the first manufacturers worldwide, producing innovative machinery and plant for the chipless and low-burr-cutting of metal tubes, including the self-developed, patented, tear/break-system. WHS is a…

More Releases for Cut

Document Shredder Market by Type, (Strip-cut, Cross-cut, Micro-cut), Growth St …

Based on previous market performance, the Document Shredder market is expected to reach USD 6.8 billion in size by 2029. With an 8.6% CAGR.

Document Shredder Market Overview:

A paper shredder is a machine that cuts papers into small pieces before throwing them away. Many government agencies, private organizations, huge firms, small businesses, and individuals utilize this to trash confidential documents and sensitive information like marketing plans, financial statements, strategic objectives,…

Plasma Cut – Your Metal Cutting Partner

Plasma Cut is one of the leading names in the laser cutting industry in South Africa. The company offers a wide-range of services which include laser cutting and the fabricating of steel, aluminium and various other metals including exotic alloys.

Services Offered by Plasma Cut:

1. Laser Cutting: Plasma Cut applies laser cutting techniques to cut stainless steel and mild steel plates. The process cuts lengths up to 6 metres and with…

Die-cut Lids Market - Rising Demand for Processed Food Vital for Die-cut Lids Ma …

The global die-cut lids market features a moderately consolidated at present, but could witness entry of several new participants rendering the market to be competitive, says a new report by Transparency Market Research (TMR). In the highly competitive market, players are strategizing on organic and inorganic growth to strengthen their footprint in emerging markets. Players are focused to leverage their core business strengths to bring new products to the market…

Introducing New Cut Resistant Sleeves - Defensor by Ronco - Cut Level 5 protecti …

Concord, Ontario Feb 29: Ronco has introduced new CE Cut Level 5 Defensor™ sleeves.

A large proportion of workplace accidents are attributed to workers not wearing or taking breaks from wearing their PPE because of discomfort. Made of 13 gauge HPPE (high performance polyethylene), the Defensor™ sleeves have a unique property of dissipating heat and is a solution to overcome discomfort even during prolonged usage. These sleeves are light-weight and…

Cut food hygienically

Bizerba presents cutting machines for counters, kitchens and catering at the EuroShop 2011 (hall 6, booth E56)

Balingen, February 26th 2011 - There are many causes for the premature deterioration of meat products. In addition to inappropriate storage and inadequate transportation, poor hygiene in further processing can also be responsible for this. The hygienic design of the Bizerba cutting machine helps food companies to minimise the risk of contamination in a…

Cut, Color, Clarity, Carat: Perfection

FOR IMMEDIATE RELEASE

Contact:

Anny Deirmenjian

Image Unlimited Communications©

P. 781.721.4624 C. 617.851.9315

E. anny@imageunlimited-boston.com

Cut, Color, Clarity, Carat: Perfection

Find the Perfect Diamond with the Boston Center…