Press release

Focus on Abrasive Cutting

In the process of abrasive waterjet cutting, the focusing tube is a vital component. After all it is in this tube where high pressure water and abrasive are focused to an efficient cutting jet. During this procedure, the physical processes in the tube crucially affect the final speed and precision of the cutting jet as well as the kerf width at the workpiece. However, which factors influence the functionality of a focusing tube?Geometry of the focusing tube

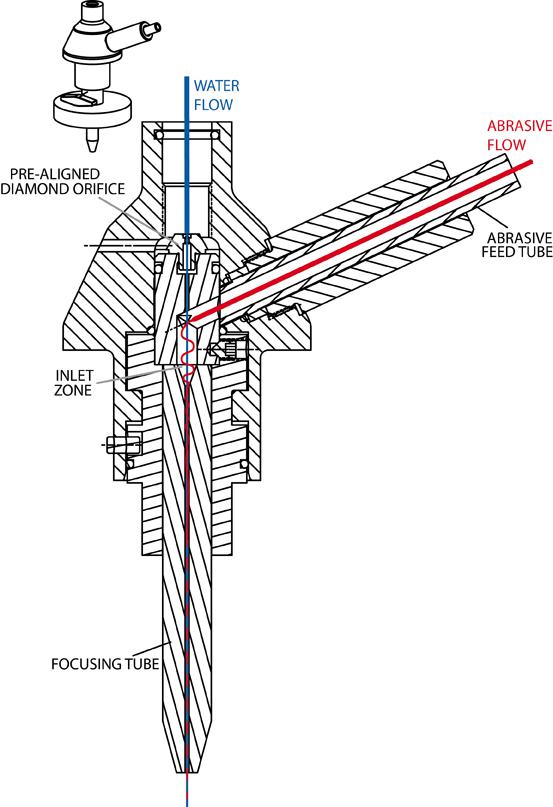

An important feature of a focusing tube is its length. In combination with the geometry of the inlet zone (see drawing), the tube length significantly determines the speed and focus of the exiting jet. The pure water jet created by a diamond or sapphire orifice (see TechNews I/2012) is enhanced with abrasive sand in the mixing chamber, which is in front of the focusing tube. In this process, both a correct inlet angle and a minimum tube length are necessary to adjust the abrasive particles to the velocity and direction of the waterjet thus creating a precisely focused and efficient cutting jet. However, the focusing tube should not be too long either as the jet will then be slowed down due to friction at the inner surface and decrease in cutting performance.

Further influencing factors

Considering the general interaction of focusing tube and water orifice, there are also some things to take into account. For example, the proportion of the respective interior diameters is important for the precise focus of the cutting jet. Moreover, tube and orifice have to be exactly aligned. Normally, a concentric, slightly wavelike wear can be observed, especially at the tube inlet. If the alignment is imprecise, the wear increases and affects the jet’s quality after a shorter period of use. This may result in a diversion of the cutting jet at the tube outlet and a deterioration of the cut quality at the workpiece. Further factors which particularly influence the product life are the inlet velocity of the waterjet as well as the amount and quality of the abrasive and of course the material quality of the focusing tube.

The Hypertube

Taking all of these features into account, the focusing tube Hypertube by KMT is first choice for many operators of waterjet cutting machines. Starting with the choice of material, KMT offers different quality levels which enable a product life of up to 120 hours – possibly even more depending on application. Considering that a long-lived focusing tube makes for a precise cut which lasts over an equally long period, a high quality tube may reduce the downtime of the whole machine. Furthermore, KMT has optimized the tube’s geometry and material with over 40 years of experience to accomplish the best possible cutting performance. The combination of the Hypertube and a KMT cutting head guarantees an exact alignment of focusing tube and water orifice as well as the right proportion of the respective interior diameter – KMT’s advice is a proportion of approx. 1:3. Moreover, the great exterior diameters resulting in a high wall thickness realizes a very good heat dissipation.

KMT Waterjet Systems is a leading multinational manufacturer of components for waterjet cutting systems. The company develops solutions for a wide range of industries and applications. Since 1971 the company has been dedicated to long-term customer relationships. Continuous investment in innovation has made KMT Waterjet Systems the market leader in the waterjet cutting industry. High pressure pumps, cutting heads, abrasive systems, high pressure tubes, original spare parts and a global service network are among the key products and services of the company.

KMT GmbH

Ralf kleine Brörmann

Hohe Strasse 4-6

61231 Bad Nauheim

Deutschland

Phone: +49 (0) 6032 / 997-126

Fax: +49 (0) 6032 / 997-270

E-Mail: ralf.broermann@kmt-waterjet.com

Internet: www.kmt-waterjet.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Focus on Abrasive Cutting here

News-ID: 234236 • Views: …

More Releases from KMT Waterjet Systems

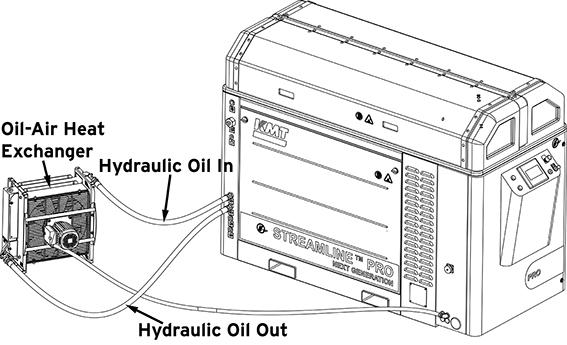

Everybody be cool – A Comparison of Cooling Systems for High Pressure Pumps

Which cooling system fits best for which high pressure pump installation for waterjet cutting? When operating a high pressure pump for waterjet cutting, it is crucial to run a reliable cooling system as some vital components of the pump may be damaged if the temperature of the hydraulic oil rises above a certain point. Therefore, KMT Waterjet high pressure pumps carry out an automatic shut-down as soon as the oil…

Quick and economical waterjet cutting with ABRALINE Advanced

(Bad Nauheim, 2013-02-06) With the ABRALINE abrasive bulk transfer system, KMT Waterjet Systems offers a solution to enable quick and economical waterjet cutting. The latest addition to this product line is the model version ABRALINE Advanced which features a larger abrasive silo and an optimized design. Thus, it is able to reliably feed demanding waterjet cutting applications. The use of such a system pays off: When cutting with a waterjet,…

More Releases for Cutaway

Online Shopping Usage and Channels of Taiwanese Netizens (Pre-order)

An extensive analysis of the Online Shopping Usage and Channels of Taiwanese Netizens (Pre-order) market strategy of the leading companies in the precision of import/export consumption, supply and demand figures, cost, price, revenue and gross margins. The report starts by an introduction about the company profiling and a comprehensive review about the strategy concept and the tools that can be used to assess and analyze strategy. It also analyzes the…

Cycling Clothing Market 2018 Global Analysis, Size, Strategies, New Trends, Shar …

This report studies the global Cycling Clothing market status and forecast, categorizes the global Cycling Clothing market size (value & volume) by key players, type, application, and region. This report focuses on the top players in North America, Europe, China, Japan, Southeast Asia India and Other regions (Middle East & Africa, Central & South America).

Cycling Clothing is pleasant to have but is not necessary. Compared with general bag, the Cycling…

TRAINING CENTRE PROMOTES BEST PUMP PRACTICE

Since 2008, Hydro Innovations has been cultivating an extensive range of products and now, with its new training centre, its capable staff are able to pass some of their expertise on to you in a truly impressive way.

Hydro Innovations' Wastewater Pumping Station

This is the centre-piece of the training centre: a fully operational installation of a Gorman-Rupp ES 200x200 sewage and wastewater pumping station. The installation stretches across two floors, with…

Voith Industrial Services Supports Ford’s Logistics Activities in Ohio, USA

Further expansion of partnership; Inspection, inventory management of new vehicles, loading and unloading of railcars; IT Solutions, Facility Management, Carrier Communications are all included in the inventory management responsibilities

Avon Lake, Ohio, USA, (January 25th, 2016) – Voith Industrial Services provides vehicle processing and yard management services for Ford’s North American operations. In addition to managing select services at Michigan Assembly Plant, Voith now supports Ford Ohio Assembly Plant in…

Yamaha To Raise Funds For Tornado Victims

BUENA PARK—Yamaha Corporation of America is helping to sponsor Music Aid for Joplin, an online auction established to help support Glory Days Music in Joplin, Missouri. A devastating EF5 tornado hit the town on May 22, killing 155 people and demolishing half of the city, including the musical instrument storefront and the home of Glory Days’ owner Dave Peterson.

Musical equipment from Yamaha and other manufacturers will be sold during…

WORCESTER HEADS TO WEMBLEY FOR PHEX 2011 STAND NUMBER 44 & 45

Worcester, Bosch Group, will be attending this year’s PHEX exhibition at Wembley Stadium on 6th and 7th April, showcasing a host of products.

Worcester’s stand will feature gas-fired boilers from the SEDBUK ‘A’ rated Greenstar series - including the I Junior and a cutaway model of the popular CDi model - alongside a number of Worcester’s current renewable products, all of which complement the high-efficiency boiler series. These include the…