Press release

Can 3D plant project data control be easy on Administrators?

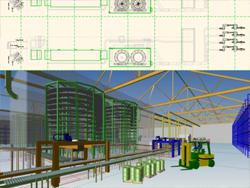

CAD Schroer‘s new Project Data Control (PDC) environment for MPDS4 ensures that concurrent plant design and global engineering content management doesn’t have to come with a huge implementation burdenCambridge, UK and Pittsford, NY – July 2012: With the release of its new PDC engineering content management environment, CAD Schroer aims to help process plant and large-scale assembly designers to effectively manage growing engineering design complexity, without a huge administrative burden.

PDC has just been launched with the latest release (5.1) of CAD Schroer’s database-driven MPDS4 3D plant design system. “Manufacturers and plant designers face growing design complexity, along with pressures on project timescales, costs and resources,” explains Product Line Manager Mark Simpson. “Engineering documents and data represent their main intellectual property. Getting the most out of this investment by controlling, sharing, re-using and querying engineering content is key to the quality, efficiency, success and profitability of future projects . Yet the administrative burden associated with implementing most PDM or PLM systems can be a massive stumbling block. PDC is our flexible approach to this issue; an attempt to go easy on Administrators. We won’t replace existing systems or databases – we provide a practical technical solution that integrates plant design with them, aligning engineering software with our customers’ objectives by delivering only what’s needed.”

PDC Video and Datasheet:

http://www.cad-schroer.com/Software/MPDS4/DataManagement/pk/178/

Integrated Project and Data Control

PDC manages all design data and associated documents, and is fully integrated with CAD Schroer’s MEDUSA4 drafting and MPDS4 plant engineering software. Its open architecture makes data available to existing PLM, PDM, ERP or analysis systems, and to other users via the Internet, allowing distributed teams to collaborate globally. PDC provides version management, user and access privilege controls, and manages all project-related content (e.g. 3D models, 2D drawings, spreadsheets, piping isometrics), as well as design-specific data (e.g. component attributes, parts lists or the current editing status of a drawing).

Intelligent Queries and Easy Updates

“When suppliers modify, replace or recall equipment regularly used in plant projects, MPDS4 users can query PDC-controlled equipment models to see in which documents they are represented - e.g. as a P&ID symbol, an MPDS4 instance, or a 2D view,” Mark explains. “They can assess the implication of making a change, and replace the equipment in their designs with the latest version if appropriate.”

Users can also explore relationships between documents, i.e. between model files and their definition sheets. PDC queries can locate similar projects, allowing users to copy databases for a quick start on new designs. PDC makes downstream engineering data, such as piping isometrics, available to other project stakeholders, or to other systems for stress analysis for example.

With PDC, plant designers can flexibly manage project complexity, effectively using engineering data without a huge implementation burden. CAD Schroer’s experts provide practical technical solutions to customers worldwide, integrating engineering and corporate processes to meet business objectives.

About CAD Schroer

CAD Schroer is a global software development company and engineering solutions provider, helping to raise the productivity and competitiveness of customers working in manufacturing and plant design, including the automotive sector and its supply chain, the energy sector and public utilities. CAD Schroer has offices and subsidiaries throughout Europe and in the United States.

CAD Schroer’s product portfolio includes 2D/3D CAD, plant design, factory layout and data management solutions. Customers in 39 countries rely on MEDUSA4®, MPDS4™ and STHENO/PRO® to provide an efficient, flexible and integrated design environment for all phases of product or plant design – cutting costs while raising quality. CAD Schroer emphasises close customer partnerships and supports its clients’ objectives through extensive consultancy, training, development, software support and maintenance services.

Michael Schroer

CAD Schroer GmbH

Fritz-Peters-Straße 26-30

47447 Moers

Website: www.cad-schroer.com

Email: info@cad-schroer.com

Telephone:

Germany: +49 2841 9184 0

UK: +44 1223 460 408

France: +33 141 94 51 40

Switzerland: +41 44 802 89-80

Italy: +39 02 38303267

USA: +1 866-SCHROER (866-724-7637)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Can 3D plant project data control be easy on Administrators? here

News-ID: 228835 • Views: …

More Releases from CAD Schroer GmbH

Project engineers explore 3D plant design software at key conferences

At ACHEMA and UK AD & Biogas 2012 CAD Schroer welcomed project engineers, plant providers and Owner/Operators to explore the possibilities offered by large-scale 3D plant design.

Cambridge, UK and Pittsford, NY – 4 October 2012: World Congress or national conference - sustainable energy was top of the agenda at ACHEMA in Frankfurt and UK AD & Biogas in Birmingham, where project engineers had the opportunity to explore flexible,…

Olympic Fever and Pedal Power Drive CAD Anniversary

It’s the 10th anniversary of the MEDUSA 2D/3D drafting software and the MPDS plant design system at CAD Schroer, and the company has been celebrating in the spirit of sports, all for a good cause.

Cambridge, UK and Pittsford, NY – August 2012: Since CAD Schroer acquired MEDUSA and MPDS, its experts have completely overhauled and expanded one of the most flexible engineering software systems on the market. Its…

3D layouts speed up process line design projects

PPMA member webinar for machinery providers highlights the benefits of 3D process line design – from bid-winning pre-sales concepts to fast, high quality project delivery

Cambridge, UK and Pittsford, NY – August 2012: Machinery providers delivering turnkey projects, who need to visualise their equipment in client factories, will learn about the ease and benefits of large-scale 3D process line design during a 45-minute webinar on 15…

More Releases for PDC

Global PDC Drill Bits Market Analysis by 2020-2025

Scope of the Report:

The global PDC Drill Bits market size is expected to gain market growth in the forecast period of 2020 to 2025, with a CAGR of xx%% in the forecast period of 2020 to 2025 and will expected to reach USD xx million by 2025, from USD xx million in 2019.

Market segmentation

PDC Drill Bits market is split by Type and by Application. For the period 2015-2025, the growth…

PDC Drill Bits Market Business Players Strategies | Halliburton, BHGE, and Schlu …

The global polycrystalline diamond compact (PDC) drill bits market is envisaged to achieve growth as oil and gas activities see a rise across the world. Over a span of recent years, there has been a drastic change observed in PDC bit technology. This could be due to improved knowledge about how drilling vibrations impact productivity. In fact, in the first place, drilling vibrations have been researched in great detail so…

PDC Drill Bits Market - Worldwide Performance Report 2025 | Halliburton, Schlumb …

Global PDC Drill Bits Market: Overview

The global polycrystalline diamond compact (PDC) drill bits market is envisaged to achieve growth as oil and gas activities see a rise across the world. Over a span of recent years, there has been a drastic change observed in PDC bit technology. This could be due to improved knowledge about how drilling vibrations impact productivity. In fact, in the first place, drilling vibrations have been…

PDC Drill Bits Market – Comprehensive Overview 2025 | Halliburton , Schlumberg …

Global PDC Drill Bits Market: Overview

The global polycrystalline diamond compact (PDC) drill bits market is envisaged to achieve growth as oil and gas activities see a rise across the world. Over a span of recent years, there has been a drastic change observed in PDC bit technology. This could be due to improved knowledge about how drilling vibrations impact productivity. In fact, in the first place, drilling vibrations have been…

Polycrystalline Diamond Compact(PDC) Bit Market Size, Share, Development by 2023

New report published by Global Info Research which offers insights on the global Polycrystalline Diamond Compact(PDC) Bit market.

Polycrystalline diamond compact (PDC) drill bits are primarily used in the drilling tools for the oil and gas industry. The fixed-head bits used in the PDC cutters for drilling are called PDC drill bits.

Click to view the full report TOC, figure and tables:

https://www.globalinforesearch.com/global-polycrystalline-diamond-compactpdc-bit-market_p87778.html

Global Polycrystalline Diamond Compact(PDC)…

PDC Drill Bits Market - Prime challenges faced over 2025 | Halliburton, BHGE

Global PDC Drill Bits Market: Overview

The global polycrystalline diamond compact (PDC) drill bits market is envisaged to achieve growth as oil and gas activities see a rise across the world. Over a span of recent years, there has been a drastic change observed in PDC bit technology. This could be due to improved knowledge about how drilling vibrations impact productivity. In fact, in the first place, drilling vibrations have been…