Press release

Desarrollo de nuevas formulaciones de masterbatches con cáscara de almendra

The introduction of these masterbatches in consumer goods will make way for their integration into the market of new sustainable products, with high performance and profitability.The Project so called is developing new colour concentrates, based on natural resources from agriculture for diverse thermoplastics. The aim is to obtain high added value masterbatches for the market and that, due to their high innovative value, they will be without competition. The concentrates developed will allow us, at first, to cover the technical requirements of two traditional industrial sectors, being those of toys and auxiliary furniture, although the achieved results could be transferred to other sectors that use injection processes.

Around 80% of plastic products made using the injection process have colorants and other additives within their formulation both, for aesthetic and functional reasons. This is the most widespread method for colouring and modifying the properties of plastics which must be compatible with the matrix polymer to which they are added.

That is why, the enterprise IQAP (colour & additives concentrates manufacturer) with AIJU’s support (technological centre for child & leisure products), is undertaking this project for the development of totally innovative masterbatches that include the natural resource of almond shell in their composition. The companies responsible for the initial testing of these color concentrates are: INJUSA, devoted to the production of children’s bicycles, electrical toys, ride ons and tricycles, and PÉREZ CERDÁ, an enterprise devoted to the Plastic Injection of auxiliary furniture among many other products.

This project, funded by CDTI within its Research & Development program (Expedient IDI-20120212) and co-funded by FEDER funds, involves great innovation and a high technological level as it will contribute to medium term sustainability and will boost the competitiveness of the toy and auxiliary furniture industries specifically, as well as that of injection in general.

The Toy Research Institute (AIJU) is a non-profit making organisation, located in Ibi, the Spanish geographic centre for the manufacture of toys. It was founded in 1985 with the collaboration of the Spanish Toy Manufacturers Association (AEFJ) and the Regional Government (IMPIVA).

Its aim is to transfer and allow toy manufacturers access to the knowledge of new technologies in order to improve their competitivity, while offering technological and financial assessment and supporting the professional development of people involved in the sector. For this purpose, it has a staff of 75 professionals who develop their work in the different departments that make up AIJU. Besides, this organization is provided with the required infrastructure to manage the different activities it undertakes.

The department intended to carry out these tasks is that of Product Development – Laboratory Department, specifically the Processing and Materials area. This area has several research lines for the development of new materials for traditional and Rapid Manufacturing processes, manufacturing & decoration processes and pre-treatments in order to optimise such processes.

AIJU is the leader of PLATECMA (Technological Platform of Traditional Manufacturer products) and an active member of the Rapid Manufacturing European Platform and the Spanish mirror led by ASERM, the Spanish Rapid Manufacturing Association, EuMAT, EFFRA the European Platform for Sports Innovation and Manufuture. AIJU is a member of the “Materials” group promoted by REDIT, the RDT Centres of IMPIVA’s Network.

In the field of standardisation, the entity is working on the potential feasibility of proposed legislation as well as new safety criteria for toys, with participation in several proficiency testing schemes both, on a National and European Level. Thus, it is participating in the development of new standards for toys in the European Committee of Normalization (CEN).

AIJU

Avda de la Industria, 23

03440 Ibi (Alicante)

Tel. 965554475

e-mail: proyectos@aiju.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Desarrollo de nuevas formulaciones de masterbatches con cáscara de almendra here

News-ID: 222333 • Views: …

More Releases from AIJU

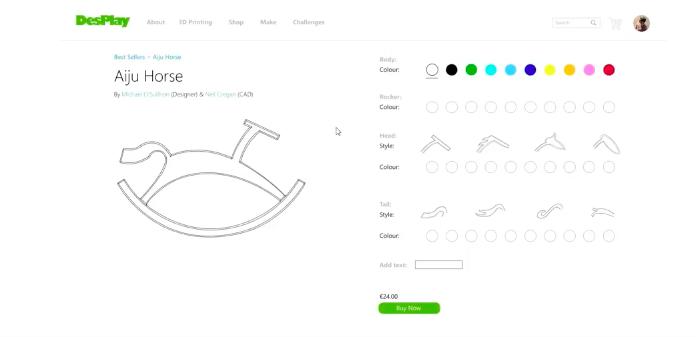

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…

More Releases for Previous

2019 TMC Mega Raffle Breaks Previous Record Final and Early Bird Winners Announc …

TUCSON, ARIZ. – March 20, 2019 — The annual TMC Mega Raffle beat it’s 2018 record with the earliest sell-out ever and the 50/50 jackpot reaching an all-time high of $728,440. Due to the early sell-out, both the Early Bird and Final prize drawings were held on Wednesday, March 13. While the final numbers are being totaled, the funds benefiting Tucson Medical Center this year are projected to surpass previous…

Farm Cleaning Solutions Market : Evaluation of previous trends 2028 | Velocity C …

Farm Cleaning Solutions Market: An Overview

Farmers are implementing effective sanitation practices during cultivation, production, and harvesting to minimize the risks related to microbial contamination in the agricultural produce. Soil, harvesting equipment, fertilizers, water, and livestock such as cows, buffalo and others can be a carrier of microorganisms that can cause infectious diseases. To prevent prevalence and contamination of microbial contamination, farmers are spending on effective farm cleaning solutions. With the…

Endpoint Management Solution for Previous Versions of Windows OS Unveiled by Far …

Leading endpoint management solution provider, Faronics, unveiled that their system recovery solution, Deep Freeze, works on XP, apart from all the other latest Windows versions. This came as a delight for XP users who are not keen on upgrading their OS anytime soon. The offering is based on the reboot to restore technology, that helps reverting configuration changes or malicious downloads with a simple reboot.

Microsoft discontinued its support…

Spectroscopy IR Detector Market - Upgradation Of Previous Spectroscopy IR Device …

Spectroscopy is a branch of science that covers the measurement and investigation of dissemination of light that is emitted by an object into colors that constitute the light. A detector that reacts to Infrared rays is called Infrared or IR detector. Photonic and thermal detectors constitute the two main types of detectors.

Infrared or IR spectroscopy is an analytical technique that is considered most important for the scientist. IR spectroscopy…

About ten percent sales growth over previous year

Halver, 23 January 2017 – ESCHA GmbH & Co. KG from Halver, Germany has closed the business year 2016 with a record turnover of more than 49 million euros. This corresponds to a sales growth of about ten percent over the previous year. The family-controlled company could also report a new record order entry. The number of employees in 2016 increased by 4.7 percent totaling 532 employees in Germany. Hence,…

NCR sells 125,000th NCR SelfServ ATM, more than doubling previous total

Company delivers state-of-the-art deposit automation ATMs to market and maintains position as world’s most popular ATM brand

LONDON – The world’s leading ATM manufacturer and service provider, NCR Corporation (NYSE: NCR), has sold its 125,000th NCR SelfServ™ ATM, more than doubling the cumulative number sold in 2008 and 2009. Now with wider availability and additional transaction options, SelfServ ATMs help hundreds of financial institutions offer better customer service. To date, more…