Press release

Precise dosing of smallest quantities: compact electromagnetic flowmeter made of stainless steel with IO-Link

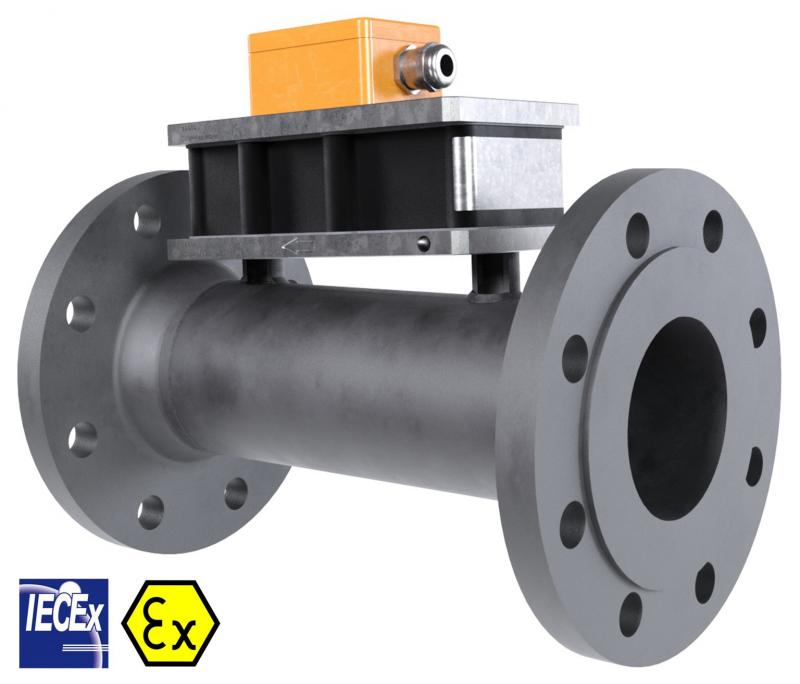

Flow measurement 4.0For precise dosing of even the smallest quantities: KOBOLD’s new electromagnetic flowmeters, even with small nominal diameters, provide precise readings in a minimum of space

Worldwide unique flowmeter combining IO-Link with remote version design

Be in pharmaceutical industry, in water treatment or in food production: If conductive media such as cooling water are added to a process, magnetic-inductive flow meters are usually installed for monitoring purposes, particularly in the context of dosing where the measuring flow meters must possess precise response times, and should also be easy to configure, otherwise incorrect dosing or insufficient repeatability will occur.

Although there are already many accurate devices for small and medium flow rates in the market place, they are often limited in functionality or lack flexibility at the installation stage. KOBOLD Messring GmbH provides these features as standard with its flow meter MIM.

Due to the extensive options for on-site programming, they are suitable for cross-industry use, particularly for dosing applications. Configurable optical buttons can be used to display parameters such as flow rates or temperatures. A changing colour system in the display also warns of limit violations. Since the MIM model is the first variant produced in a remote version, in which the display and electronics are not integrated in the sensor unit, the flow meter can also be used for media temperatures from -40°C up to +140 ° C.

For reference, `Magnetic-inductive flow meters work without moving parts, unlike rotating vane flow meters, and for this reason they hardly show any signs of wear & tear. As a result, these devices have proven to be effective in measuring the flow of conductive media – such as water, pulps and pastes, juices or emulsions, explains Raza Ali Agha, Sales Director at KOBOLD Messring GmbH; "however, this wide range of applications also leads to very different installation situations, since the measuring instruments are used in various industries and processes.

The nominal size of the connected pipes, possible orientation during installation and integration into certain process chains, such as dosing of media during coating of tablets or during coolant supply, influence the choice of a suitable flow meter, particularly in the context of dosing processes where the measuring instruments must offer the possibility of programming intermediate values in order to document the quantities, and to avoid inaccurate dosing. In addition, the display should be multi-line and clearly visible so that the plant engineers are warned in good time before exceeding a limit value. Often however, flowmeters only meet some of these requirements, and often at the expense of usability".

For this reason, KOBOLD Messring GmbH developed the product MIM; universal flow meter incorporating IO-Link to meet Industry 4.0 requirements (if or when required), which are suitable for almost any measuring situation and guarantee high programming freedom in addition to good response times of sometimes less than 100 milliseconds. On the one hand, the numerous functions such as temperature measurement or dosing are performed accurately, which can be set in just a few steps in the program menu with the hot key buttons. On the other hand, the robust and flexible design enables simple and clear installation, even in tight-fitting pipe systems.

Installation in extreme conditions thanks to remote version

The MIM is completely made in stainless steel. In addition to the temperature measurement function, the MIM can be used for very small nominal pipe sizes and covers an even larger measuring range, depending on the nominal size - from 30 ml /min upwards. "The flow meters have two individually configurable outputs that can act as a pulse, alarm or analogue output, depending on the setting," explains Raza Ali Agha. "This makes them easier to integrate into different processes or auxiliary circuits." The colour multi-display can also rotate digitally in 90 ° increments, so that when changing location, no other model is required, and the display is independent of the position of the connections.

The response time has now been improved to facilitate more precise dosing quantities. In addition, different subsets can be programmed via the menu in order not to have to navigate awkwardly with each new setting through the menu. The display has also been extended to so-called hotkeys. With this feature, the desired dosage can be conveniently selected by optical buttons on the home screen. The desired dosing process can be started and stopped via an external control input, and, the quantity can also be changed via MIM at any time. "Precisely measured quantities and a very good response time are indispensable, especially for sensitive processes such as tablet coating," confirms Raza Ali Agha.

To ensure that this possibility is also available for hot media and in extremely temperature-controlled environments such as cooling water circuits, KOBOLD is offering for the first time a device in remote version. Unlike conventional devices, the media-contacting unit only contains the sensor. The entire electronics, the control and display, are housed separately and connected via a cable at a safe distance to the sensor unit on the pipe. As a result, even temperatures from -40°C up to +140 ° C are not problem and the flow meter can work trouble-free because the electronics remain protected.

Basic building block for every measurement project

The flexibility of this flow meter family is also reflected in the user guidance and the range of functions. Almost all settings can be comfortably done on the display via four optical buttons. Functions such as partial counter display, temperature measurement or maximum flow can also be applied to the mentioned hotkeys so that you do not have to constantly navigate through multiple control levels in the menu. This can also be done with a glove, as the buttons have different sensitivity levels. The multi-line display offers a better overview than comparable compact devices and can also display the corresponding unit, or other information in addition to the measured value. This clarity is further enhanced by the multicolor of the display: For example, the color changes when a certain flow rate has been reached. As a result, the user also sees from a distance when for example, a certain amount has been dosed or a limit has been exceeded.

"During the conception phase, we used testimonials from our customers in a wide range of industries to develop a very flexible and reliable universal device. With MIM, there is now flow meter for almost every measurement task, "summarizes Agha.

KOBOLD Messring GmbH

Nordring 22-24, 65719 Hofheim/Taunus

Phone: 06192 299-0, Fax: 06192 233-98

E-mail: grafik@kobold.com

Internet: www.kobold.com

KOBOLD Messring GmbH was founded in 1980 and is one of the leading companies in the field of industrial measurement and control equipment. It develops permanently installed sensors as well as professional hand-held devices for recording and monitoring physical variables such as flow, pressure, level and temperature. In addition to flow meters and level meters, the range also includes pressure measuring devices, temperature monitoring, pH and redox determination, and devices for measuring the moisture or turbidity. Due to the modular design and the high calibratability of the devices, they are used in almost all industrial sectors. Since 2019, the company has been offering a separate flow meter with IO-Link, which can also be used at temperatures from -40 to +140 ° C. The company employs over 200 people in Germany.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Precise dosing of smallest quantities: compact electromagnetic flowmeter made of stainless steel with IO-Link here

News-ID: 2152581 • Views: …

More Releases from Kobold Messring GmbH

REG - water regulation made easy

Mechanical flow restrictor from the house of Kobold

Mechanical flow restrictors REG from instrumentation specialists based in Hofheim am Taunus, impress with their simple and effective functionality.

Once installed, the REG limits the flow to a preset fixed value, regardless of pressure fluctuations. Due to the high quality stainless steel design, the REG is completely maintenancefree. With no auxiliary power and secure from manipulation, the REG is particularly suitable for consumer applications…

Oscillation Flowmeters for Dry and Wet Gases

Oscillation is a measurement method that is unique for gases and can be used in a variety of ways for flow measurement with the aid of a flow oscillator. With this unique measuring method, a partial flow of the medium is passed through a bypass into the oscillator. In the oscillator, the medium flows through a chamber with two flow channels. A bluff body deflects the flow either in one…

The first Digital Pressure Gauge worldwide with IO-Link - optionally as Battery …

Kobold have released the latest version of their electronic digital pressure gauge; model MAN-SC for battery powered, and model MAN-LC for 24Vdc power with IO-link.

Outwardly the two versions are similar in appearance and share most of the screen functionality features which are now accessed via capacitive Touchpads, however, depending on the application and use, each instrument version may be defined differently. For example, the battery powered instrument defined as…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…