Press release

Electric Resistance Welding (ERW) Pipes & Tubes Market Supply, Sales, Revenue and Forecast from to 2025

Welded pipes are pipes that have welded seam across their length. Electric resistance welding (ERW) is one of the many processes of manufacturing welded metal pipes. This process is used to manufacture pipes and tubes with lower wall thickness. In ERW, a flat strip of the metal is passed through a series of rollers to mold them in a cylindrical shape. This cylindrical shaped pipe is then welded by passing a high frequency electric stream between the edges and forcing them together to make a bond. These pipes and tubes are used in various applications in industries such as building & construction, automotive, and oil & gas.Increase in demand for ERW pipes and tubes in automotive and extensive use of these pipes and tubes in the building & construction industry are factors driving the ERW pipes & tubes market. This is prompting companies to increase the production of these pipes and tubes. Additionally, easy availability of raw materials is anticipated to boost the demand for ERW pipes and tubes in the near future.

Read Report Overview @

https://www.transparencymarketresearch.com/electric-resistance-welding-pipes-tubes-market.html

The global ERW pipes & tubes market is witnessing technological advancements. Companies are constantly striving to develop new and better ways to manufacture these pipes. Development of new manufacturing processes of electric resistance welding pipes & tubes and applications is estimated to propel the market. However, the threat of substitution from seamless pipes is projected to hamper the market.

Based on material, the ERW pipes & tubes market can be divided into steel, copper & alloys, nickel & alloys, and others. The steel segment of the ERW pipes & tubes market is anticipated to expand at a significant pace owing to the increase in demand from emerging economies such as India and China.

In terms of application, the ERW pipes & tubes market can be segregated into oil & gas, infrastructure & construction, power generation, automotive, engineering, and others. The oil & gas segment of the ERW pipes & tubes market is anticipated to expand at a considerable pace due to the rise in demand for these pipes in upcoming oil & gas projects across the globe.

Based on geography, the ERW pipes & tubes market can be split into North America, Latin America, Asia Pacific, Europe, and Middle East & Africa. Asia Pacific is anticipated to constitute key share of the market during the forecast period. The ERW pipes & tubes market in Asia Pacific also estimated to expand at a considerable pace owing to the increase in demand for these pipes & tubes in infrastructure & construction and automotive sectors in the region. Middle East & Africa is likely to be an attractive region of the ERW pipes & tubes market during the forecast period due to the rise in demand for these in the oil & gas industry.

Request Report Brochure @

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=38756

Prominent players operating in the global ERW pipes & tubes market include Nippon Steel & Sumitomo Metal Corporation, Arcelormittal S.A., JFE Holdings, Inc., and Tenaris S.A.

Contact Us

90 Sate Street, Suite 700,

Albany, NY 12207

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Website: https://www.transparencymarketresearch.com

About Us

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electric Resistance Welding (ERW) Pipes & Tubes Market Supply, Sales, Revenue and Forecast from to 2025 here

News-ID: 1895694 • Views: …

More Releases from Transparency Market Research

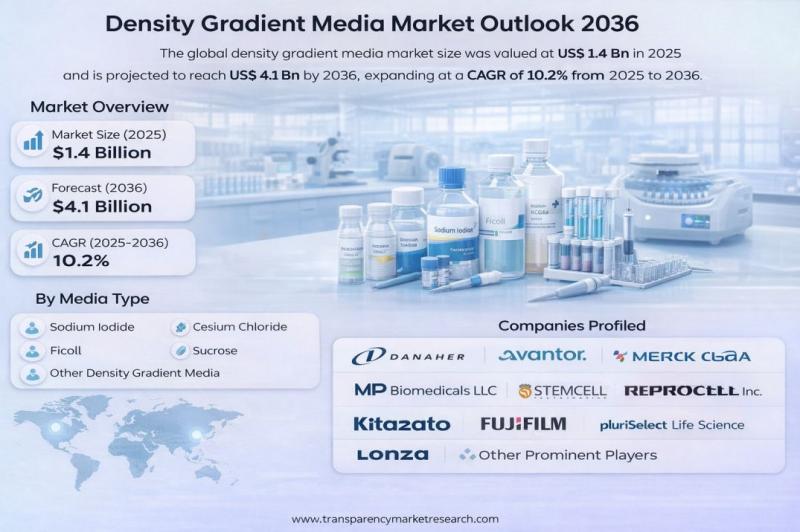

Density Gradient Media Market to Reach US$ 4.1 Billion by 2036, Driven by Rapid …

The global density gradient media market was valued at US$ 1.4 Billion in 2025 and is projected to reach US$ 4.1 Billion by 2036, expanding at a robust CAGR of 10.2% from 2025 to 2036. The market's rapid growth is primarily driven by increasing demand for rapid infectious disease screening, expanding cell therapy and immunology research, and continuous technological advancements improving sensitivity and multiplexing in laboratory workflows.

Access key findings and…

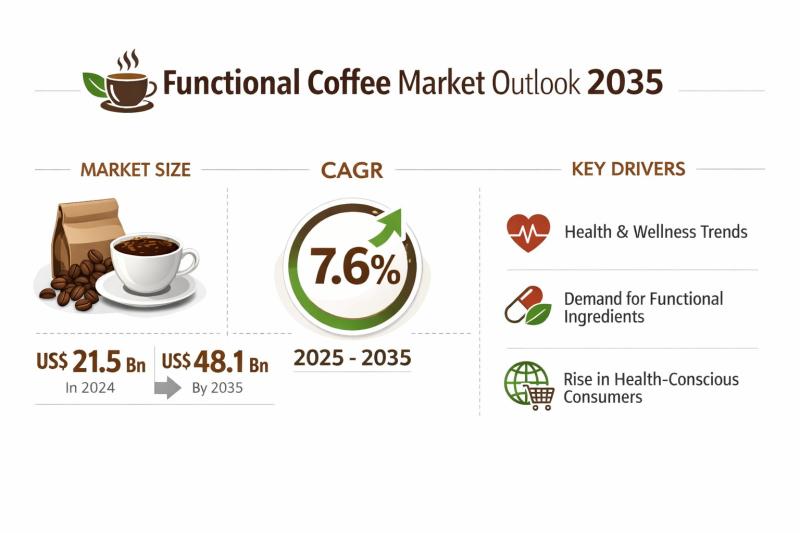

Functional Coffee Market Expanding at 7.6% CAGR Through 2035 - By Product Type / …

The global functional coffee market was valued at US$ 21.5 Bn in 2024 and is projected to reach US$ 48.1 Bn by 2035, expanding at a compound annual growth rate (CAGR) of 7.6% from 2025 to 2035. This steady growth trajectory reflects the strong convergence of coffee consumption habits with rising demand for functional and wellness-oriented beverages. Functional coffee has transitioned from a niche category to a mainstream product offering,…

Global Electric Face Cleanser Market Poised for Robust Growth, projected to Reac …

The global electric face cleanser market is witnessing a transformative growth phase as consumers increasingly integrate advanced skincare technologies into their daily routines. Valued at USD 9.8 billion in 2025, the market is projected to expand significantly and reach USD 23.6 billion by 2036, growing at a healthy compound annual growth rate (CAGR) of 8.6% from 2026 to 2036. This growth trajectory underscores the rising importance of personal care technology,…

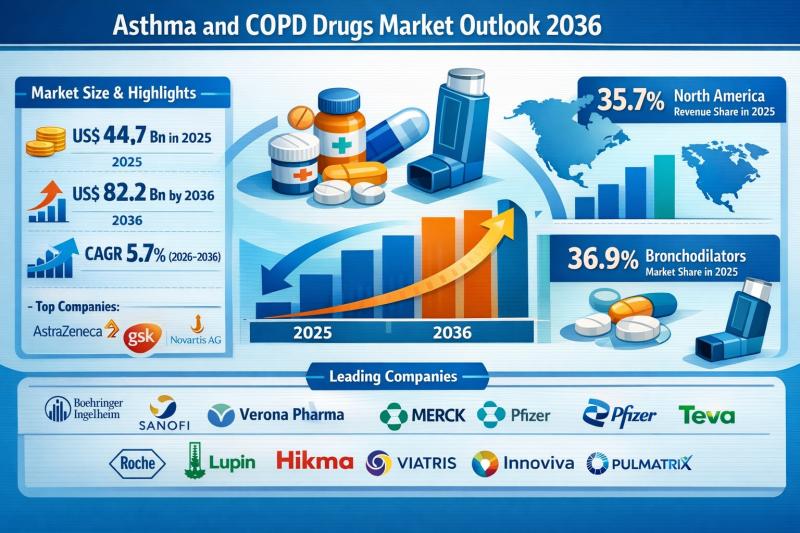

Asthma and COPD Drugs Market to Reach US$ 82.2 Billion by 2036, Growing at 5.7% …

The global asthma and COPD drugs market demonstrated strong fundamentals in 2025, with a valuation of US$ 44.7 Bn, reflecting the essential and recurring nature of respiratory therapeutics. Supported by a growing patient base and continuous pharmaceutical innovation, the market is projected to reach US$ 82.2 Bn by 2036, expanding at a compound annual growth rate (CAGR) of 5.7% from 2026 to 2036.

This growth trajectory highlights the increasing reliance on…

More Releases for ERW

ERW Pipe Mill Round To Square Sharing - ZTZG

When people make round pipes of different specifications, the molds for the forming part of Zhongtai Pipe Technology's Erw tube mill [https://www.ztzgsteeltech.com/120x120x4-erw-pipe-mill-machinesquare-sharing-rollerszfii-b-7-product/]are all shared and can be adjusted automatically. This means that people don't have to switch molds for different pipe sizes, saving them significant time and effort. Zhongtai's advanced technology ensures that the adjustment process is seamless and precise, allowing for high efficiency and consistent quality in their production…

ERW pipe standard

Electric Resistance Welded (ERW) pipes are a widely used type of steel pipe known for their versatility, cost-effectiveness, and applicability across various industries. In this comprehensive guide, we will explore the characteristics, manufacturing processes, standards, and applications of ERW pipes, shedding light on their significance in construction, infrastructure, oil and gas, and other sectors.

1.Introduction to ERW Pipes

ERW pipes are steel pipes manufactured through the process of electric resistance welding, which…

Explanation of Common Defects in ERW Welded Pipes

Explanation of common defects in ERW welded pipes:

Undercut

Undercut is a groove that appears along the centerline of the weld in the transition area between the edge of the weld and the pipe body. Undercut occurs when welding speed, current, voltage and other conditions are not properly matched.

lap welding

The upper and lower edges of the steel plate are misaligned and butted, resulting in uneven welds, which become pipe seam misalignment or…

The Differences Between ERW and Seamless Steel Pipes

The Differences Between ERW pipes(https://www.eastern-steels.com/products/erw-steel-pipe.html) and Seamless Steel Pipes(https://www.eastern-steels.com/products/carbon-steel-seamless-line-pipe.html)

Steel pipes are used in a wide range of applications, from oil and gas pipelines to structural steel and more. Two of the most common types of steel pipes are ERW pipes and seamless pipes. While both types of pipes are made from high-quality steel, there are some significant differences between the two. In this article, we will explore the differences between…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Performance Comparison of ERW and Spiral Steel Pipe

Performance comparison of carbon ERW steel pipe and spiral steel pipe:

1. Overview

The welding of ERW steel pipe is the skin effect and proximity effect of high-frequency current. The process of using high-frequency current and induced high-frequency current (rising at the end of the 20th century) resistance to heat and melt the edge of the tube blank, and apply squeezing force to weld together process.

The welding of SSAW steel pipe is…