Press release

SABIC Paints a Bright Future for Laser Direct Structuring with New Custom-Colorable LNP* Thermocomp* Compound

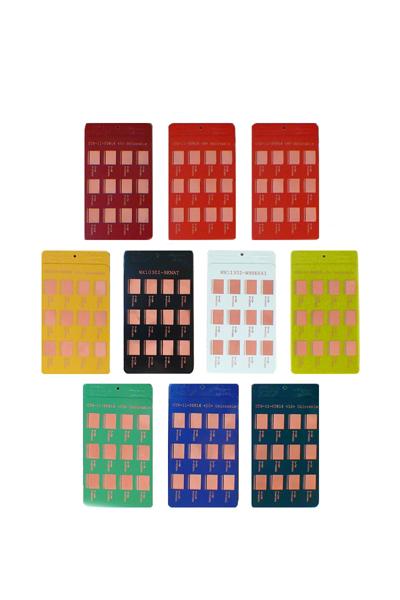

BERGEN OP ZOOM, The Netherlands – June 9, 2011 – The Innovative Plastics strategic business unit of SABIC announced at Chinaplas, the first new custom-colorable LNP* Thermocomp* thermoplastic compound for laser direct structuring (LDS) to save space and reduce the weight of mobile devices. LDS is a sophisticated process for integrating electronic and mechanical functionality into a single module, such as mobile phone and notebook antennas. Previously, only black plastic materials were available, typically forcing designers to confine LDS components to the device’s interior. The introduction of the company’s new colorable LNP Thermocomp compound vastly expands device design options. This new material introduction demonstrates Innovative Plastics’ pioneering leadership in advanced technologies for the design and manufacture of tomorrow’s portable devices.“LDS is a powerful technology for achieving greater miniaturization in mobile phones, notebooks and tablets, but until now, it had aesthetic limitations,” said Cathleen Hess, global product marketing director, LNP, Innovative Plastics. “By developing a colorable material for LDS applications, Innovative Plastics has improved upon an already successful technology.”

Innovative Plastics has worked with LPKF Laser & Electronics AG – an industry leader in LDS technology – for a number of years, first introducing the original black material technology solution. With the addition of Innovative Plastics’ new colorable LNP Thermocomp compound and LPKF’s LDS expertise, the companies are uniquely positioned to help drive customer growth.

“This breakthrough from Innovative Plastics opens the door to many new possibilities for designing molded interconnect devices using our patented laser technology," said Nils Heininger, vice president Cutting & Structuring Laser, LPKF Laser & Electronics. "The ability to integrate antennas, sensors and other functionality into the housing of a device can help drive greater part consolidation and enable slimmer, smaller designs. Moving from basic black to custom colors is a huge step forward and promises major competitive advantages for our joint customers."

LPKF’s LDS technology uses specialized lasers to scribe the circuit layout of a component onto a molded plastic part. The layout is then plated, with the resulting circuit pathway conforming exactly to the laser pattern. Innovative Plastics’ new colorable LNP Thermocomp compound has been validated and certified by LPKF for use on their equipment. Potential application areas include integrated light emitting diodes (LEDs) and connectors.

LNP Thermocomp Offers Top Performance and Aesthetics

In addition to its custom colorability and excellent surface finish for attractive aesthetics in external housings, LNP Thermocomp NX11302 specialty compound provides desirable performance attributes for electronics applications. These include high impact resistance for durability, high flexural modulus for thin wall and good dimensional stability. This polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS)-based compound offers a wide processing window and is easily plated.

For additional information on Innovative Plastics’ LNP Thermocomp products, please go to www.sabic-ip.com. For technical product inquiries, please contact us at www.sabic-ip.com/prtechinquiry.

About SABIC Innovative Plastics

SABIC Innovative Plastics is a leading, global supplier of engineering thermoplastics with an 80-year history of breakthrough solutions that solve its customers’ most pressing challenges. Today, SABIC Innovative Plastics is a multi-billion-dollar company with operations in more than 35 countries and approximately 9,000 employees worldwide. The company continues to lead the plastics industry with customer collaboration and continued investments in new polymer technologies, global application development, process technologies, and environmentally responsible solutions that serve diverse markets such as automotive, electronics, building & construction, transportation, and healthcare. The company’s extensive product portfolio includes thermoplastic resins, coatings, specialty compounds, film, and sheet. SABIC Innovative Plastics (www.sabic-ip.com) is a wholly owned subsidiary of Saudi Basic Industries Corporation (SABIC).

About Saudi Basic Industries Corporation

Saudi Basic Industries Corporation (SABIC) ranks among the world’s top petrochemical companies, and is a global market leader in the production of polyethylene, polypropylene, advanced thermoplastics, glycols, methanol and fertilizers. SABIC manufactures with a global footprint in Saudi Arabia, the Americas, Europe and Asia Pacific. The company operates in more than 40 countries across the world with 33,000 employees worldwide. It has significant research resources with 18 dedicated Technology & Innovation facilities in Saudi Arabia, the USA, the Netherlands, Spain, India and China. SABIC recorded a net income of SR 21.59 billion(US$ 5.73 billion) in 2010, and sales revenues totaled SR 152 billion (US$ 40.5 billion).

# # #

® SABIC is a registered trademark of SABIC.

* Trademarks of SABIC Innovative Plastics IP B.V.

Marketing Solutions

Kevin Noels

Box 6

2950

Kapellen

Belgium

0031164317011

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SABIC Paints a Bright Future for Laser Direct Structuring with New Custom-Colorable LNP* Thermocomp* Compound here

News-ID: 178812 • Views: …

More Releases from SABIC Innovative Plastics

SABIC Launches Portfolio of Antimicrobial Compounds at MD&M West to Help Custome …

According to a 2011 report by the World Health Organization, in 2002 in the United States alone approximately 99,000 deaths were linked to healthcare associated infections (HCAIs).1 Here at MD&M West (booth #1701), SABIC’s Innovative Plastics business today introduced powerful new tools to help medical device manufacturers reduce HCAIs among patients and clinicians. SABIC’s nine new antimicrobial compounds featuring silver technology have been tested for log reduction values – the…

SABIC’s 3D-Formed LEXAN™ Sheet Increases Visibility, Safety, Comfort and Per …

Operators of logging equipment require exceptional visibility and protection against debris or large objects that may enter their cabin and cause serious injury in forest environments, such as tree limbs and other machinery parts. So when Rottne Industry AB needed a high-performance glazing material for the windshields and windows of its harvesters and forwarders, it turned to

SABIC’s Innovative Plastics business for support. Working with SABIC and its distributer, Vink…

Mitsubishi Motors Corporation Selects SABIC NORYL GTX™ Resin for 2013 Outlande …

SABIC’s Innovative Plastics business today announced that Mitsubishi Motors Corporation (MMC) has chosen SABIC’s next-generation NORYL GTX™ 989 resin for the front fenders of its 2013 Outlander Sport crossover. The vehicle’s fenders are the first to be produced using 2-cavity injection molding with NORYL GTX resin, allowing MMC to cut cycle times in half and reduce tooling costs. Other major benefits of the SABIC material include weight savings vs. steel…

SABIC Makes a Splash at Fakuma with New NORYL™ Resin, Meeting Tightening Globa …

Here at the Fakuma trade fair, booth #B5-5506, SABIC’s Innovative Plastics business today announced a new NORYL™ resin that not only complies with current European and global sustainability regulations governing materials used in potable water systems, but also with new, tougher regulations slated to go into effect in 2016. Developed at SABIC’s Fluid Engineering Center of Excellence in the Netherlands, NORYL FE1630PW resin is a 30-percent glass-reinforced polyphenylene ether (PPE)…

More Releases for LDS

Global LDS Antenna Market to Witness a Pronounce Growth During 2025

LP INFORMATION recently released a research report on the LDS Antenna market analysis, which studies the LDS Antenna's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global “LDS Antenna Market 2020-2025” Research Report categorizes the global LDS Antenna market by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players analysis, market share, growth…

Global LDS Antenna Market Expected to Witness a Sustainable Growth over 2025

LP INFORMATION recently released a research report on the LDS Antenna market analysis, which studies the LDS Antenna's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global “LDS Antenna Market 2020-2025” Research Report categorizes the global LDS Antenna market by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players analysis, market share, growth…

LDS Antenna Market to Record Study Growth, Geography Trends & Forecasts by 2025

Get free sample at https://www.reportsnreports.com/contacts/requestsample.aspx?name=1696586

This report presents the worldwide LDS Antenna market size (value, production and consumption), splits the breakdown (data status 2013-2018 and forecast to 2025), by manufacturers, region, type and application.

This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter's Five Forces Analysis.

The LDS Antenna market was valued at Million US$…

LDS Antenna Market Size 2017-2022 Molex, SelectConnect, Pulse Electronics

LDS Antenna Market Size 2017-2022 Molex, SelectConnect, Pulse Electronics

Recently published a detailed market study on the "LDS Antenna Market" across the global, regional and country level. The report on the global LDS Antenna market uses the top-down and bottom-up approaches to define, analyze, and describe the LDS Antenna market trends for the next five years And LDS Antenna market Size and Share. The LDS Antenna market report further provides production,…

United States Laser Direct Structuring (LDS) Antenna Market Report 2017

In this report, the United States Laser Direct Structuring (LDS) Antenna market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Geographically, this report splits the United States market into seven regions:

The West

Southwest

The Middle Atlantic

New England

The South

The Midwest

with sales (volume), revenue (value), market share and growth rate of Laser…

Newport Introduces CONEX-LDS - Ultra Compact, High-Precision Electronic Autocoll …

• New integrated controller features angular measurement sensitivity of 0.01 µrad

Newport Corporation, a worldwide leader in laser and photonic solutions that Make, Manage and Measure Light®, introduces CONEX-LDS, an ultra-compact, high-precision electronic autocollimator. The small and versatile controller is integrated into the optical head of the autocollimator, occupying only 4 in. x 1.5 in. x 1.5 in. (volume). Newport's new instrument will replace the legacy LDS1000 to offer the…