Press release

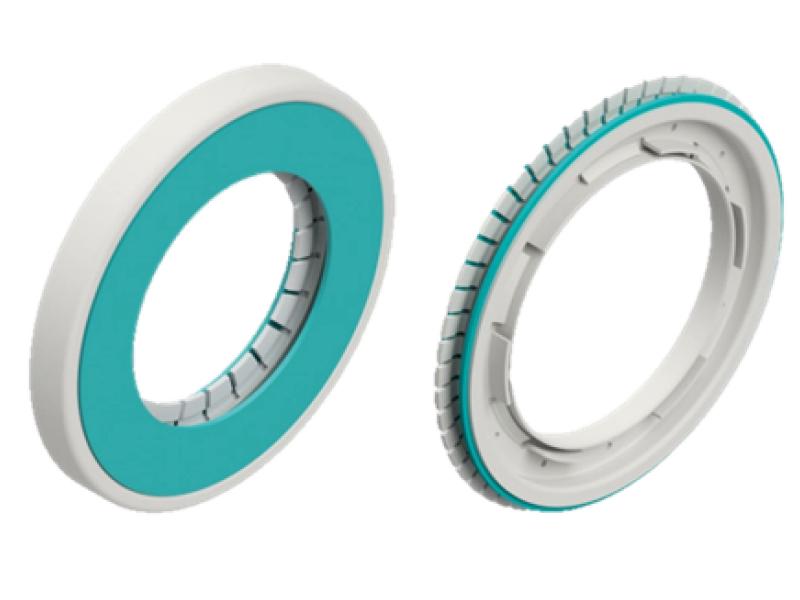

Simplicity solves complexity – venting caps by KACO

The expert for sealing solutions meets highest specifications. By presenting the patented venting cap KACO offers a rather simply looking rubber product matching a well-known complex task for breather systems.Application scope for KACO venting caps: In applications like gearboxes, axle drives, battery housings but also ECUs there is basically a need for ensuring constant venting or breathing conditions, as for instance pressure differences based on temperature change need to be balanced. Besides this there is a request for so-called “roll-over-breather” solutions which prevent oil leakage in an emergency case of a car roll-over in an accident. KACO solves this complex specification with a relatively simple looking part – the so-called venting cap. This single component part can be assembled directly into the application using for instance a small pipe as well as placing it decentral with a hose or tube in between. Assembly is really easy either to be done in-line or if helpful also after the “end of line test” if this is helpful for the leakage test of the application itself. The patented design makes it possible to ventilate in correlation to a pressure difference between the in- and outside of the application by keeping water and dust out of the system. KACO’s venting cap is already in mass production since 2012 which makes is available as an of-the- shelf product as well as a customized solution for new specifications. Latest software tools for simulation and design work are used for doing that. The venting cap can be adjusted to different IP protection classes, like splash water or flooded conditions. Dependent on the water tightness specified there are different opening and closing pressures for the venting cap, which is always aligned with the customer requirements. Also for existing systems it is basically possible to expand to the KACO venting cap solution.

Use case tested under real life conditions: The expert for sealing solutions sets value on testing his products intensively on model test rigs, for perfectly fulfilling customer requirements. For that reason specific test rigs have been created for the venting cap. For ensuring stable quality for mass production there is specific measurement equipment available. There is an ongoing design process all around the KACO venting caps in order to be capable of dealing with all kinds of applications of conventional and new energy car’s powertrains as well as other fields of usage in general industry.

„It is amazing that this simple looking rubber part can deal with such a complex specification. There is a lot of engineering inside our venting caps and this is also the reason why they are already a standardized part in many bills of materials of our global customers’ applications. No matter for which kind of automotive drivetrain, like gasoline, diesel, hybrid or battery electric cars, KACO’s venting cap is first choice for fulfilling automotive standards. But also for non-automotive applications this product can be used of the shelf or as customized product being specifically engineered by our global team” says Vice President Research & Development Andreas Genesius delighted.

KACO GmbH + Co. KG

Industriestraße 19

74912 Kirchardt

Kerstin Adam

Manager Marketing

07266 9130-0

www.kaco.de/en

The Expert for Sealing Systems

KACO GmbH + Co. KG, a subsidiary of the Zhongding Group, is one of the world’s leading developers and manufacturers of high-precision, practical sealing solutions for the automotive and mechanical engineering sectors. The company, with its headquarters in Germany, has earned a reputation for the highest quality sealing solutions and innovative power as well as for expertise in development and production. KACO has six production facilities in Germany, Austria, Hungary, China and the USA and delivers products across the globe. A trusted partner of the automotive and supplier industry, the company has been keeping pace with the high demands and technical changes of the industry for decades.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Simplicity solves complexity – venting caps by KACO here

News-ID: 1786061 • Views: …

More Releases from KACO GmbH + Co. KG

Sealing expert expands portfolio of shaft grounding rings

In addition to the application oriented adaptation of given sealing technologies, KACO has been offering new product segments for several years and is constantly developing them further. These novel product segments also include shaft grounding rings, which ensure excellent protection of the bearings and gearing of electrical machines over their operating life. Through close cooperation with vehicle manufacturers and system suppliers, as well as intensive development work, KACO offers a…

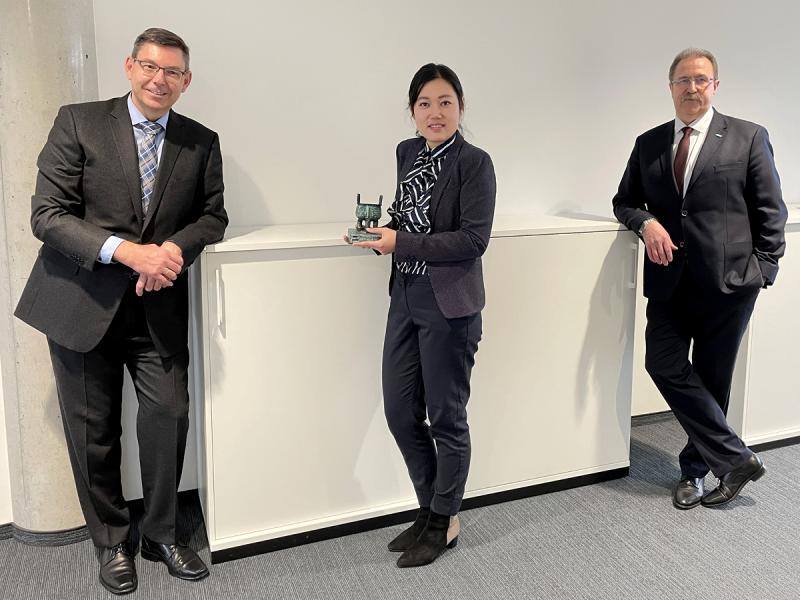

February 2021 – KACO: Reorganization of the top management

KACO GmbH + Co. KG starts with a new top management line-up into the business year 2021.

With effect from 01.02.2021 the top management of the KACO group is represented by Richard Ongherth (CEO), Yanfang Sun (CFO) and Gernot-Alois Feiel (COO).

Richard Ongherth, who has been with the company for more than 25 years, has successfully managed the operational areas as Managing Director in the past 12 years. He was responsible…

Development competence of the sealing expert KACO

For the sealing expert from Kirchardt, tradition and progress are not opposites, but the basis for the company's success, which began over 100 years ago. KACO regards knowledge and experience of its employees and its development, application and system competence as the most important resource. Together with its customers, the company will continue to be on the pulse of the times in order to bring new innovative products and solutions…

EvolIft� - Lift Off for minimal friction

In order to achieve the European Union's climate protection targets, CO2 emissions at fleet level must be reduced to < 60g CO2/km by 2030. The contribution of the sealing industry is, to reduce power losses to a technically possible minimum. KACO has further developed a principle based on turbine technology to enable its application in the automotive sector as well as in other industrial areas. The dynamic seal with the…

More Releases for KACO’s

KACO Shaft grounding rings for electric vehicle propulsion systems

The electrification of powertrains is in full progress. Besides systematically applying established sealing technology in hybrids and e-drives, KACO is offering innovative e-mobility products since a couple of years. For reliable operation of electric engines, KACO developed a product portfolio for shaft grounding rings. KACO shaft grounding rings are providing an excellent bearing protection over lifetime. The specifically dedicated, high-performing test facilities ensure functionality of the shaft grounding rings under…

Face Seals for Rotor Shaft Cooling of Electric Engines

In times of an increasing electrification of powertrains technical solutions are required to prevent the electrical engines from overheating. For that use case the expert for sealing solutions developed face seals for rotor shaft cooling to directly cool down the shaft of the rotor internally.

KACO’s face seals that have been specifically developed for rotor shaft cooling are axial acting systems for high speed (up to 37 m/sec), pressure application (up…