Press release

Energy-Conserving Suction of Aerosols & Smoke at a Dörries Scharmann Machining Center

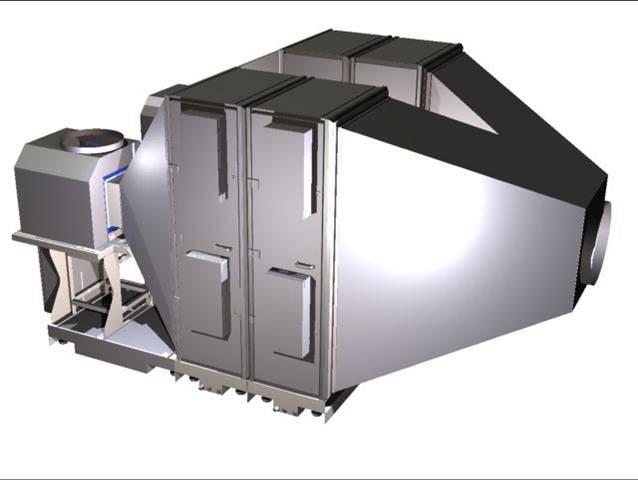

The Alstom Power Service company in Berlin is active in service, maintenance & repair of turbines for power generation. At a Dörries Scharmann machining center, a lot of emulsion mist and smoke escaping through the not 100% capsuled machine cover is produced during the turning/milling processes due to the large size of the parts. It was LTA's task to prevent just that. An LTA air filter type AC 3061 was installed which extracts the generated aerosols and the smoke with an effective suction output of max. 7,400 m³/h. At the same time, the cleaned exhaust air of the filter is used to place an air curtain over the ports at the machine which prevents remaining smoke from escaping to the environment. The particles entering the air flow are precisely directed to the exhaust ports of the filter and cleaned there.Please read the comments by the project manager at Messrs. Alstom Berlin on the LTA solution:

1.) Which were the decisive arguments in favor of LTA?

• LTA offered a solution which prevents heat from being extracted from the hall. The cleaned air is fed back.

• The air curtain solution is highly compact as no large cover for sealing the ports at the machine must be installed.

• Big effect with relatively little effort. Other offers were based on the extraction of large air volumes which also prevented aerosols from escaping, which on the other side, however, required an anormous - not so say expensive - effort. While the cooling effect would have had affected the geometry of the machine with other solutions offered, LTA avoided this thanks to the low suction output.

2.) How was the cooperation between Alston and LTA from the tendering phase right up to the completion of the project?

Consultation at LTA was highly competent. Project engineering and technical preparation during the planning phase were elaborate and with great attention to detail also in respect of the 3D drawings. In this way, problems could be revealed and made clearly visible which was followed by efficient problem solution.

The execution and completion of the project was well accompanied by LTA providing efficient support.

3.) How does Alstom benefit from the project and in how far has the exhaust air problem improved for Alstom?

Within the Alstom group, great attention is attached to the working conditions for employees. Using an EHS (Environment, Health and Safety) Roadmap, the requirements of which usually exceed the legal regulations by far, strict specifications in this regard were imposed. This project is a showcase for the rest of the Alstom corporate group.

The results obtained concerning the air quality outside the machine are very good. Another effect is the improved climate inside the machining area.

The scope of delivery of LTA for this project comprised the cleanable air filter system type AC 3061 including attachments and accessory, external operating panel and console, one nozzle plate for optimized filtering coverage, the complete pipework, the related return containers as well as the assembly and commissioning of the complete system.

The advantage of this system is the high separation degree of the electrostatic filter as well as the use of regenerative filter elements. Thanks to the use of regenerative filter elements, the filters may be cleaned as often as required which eliminates the high disposal and purchase costs for replacement filters. In excess of this, an energy-efficient and energy-saving operation becomes possible due to the low pressure loss of the electrostatic filter. With just 4.8kW, a standard blower output of 16.800m³/h is achieved.

LTA Lufttechnik GmbH

Junkerstraße 2

D - 77787 Nordrach

Tel.: +49/7838/84-245

Fax: +49/7838/84-308

Email: info@lta.de

Homepage: www.lta.de

press contact:

Hr. Philipp Fehrenbach

sales office-duty and marketing-manager

Tel.: +49/7838/84-331 (Fax: -308)

Email: philipp.fehrenbach@lta.de

LTA Lufttechnik is a renowned partner for complete solutions in air technology. The company projects, builds and delivers air filter and fire protection systems for trade and industry. For over 30 years, LTA has been researching, developing and manufacturing aerosol separation products. The electrostatic separation method is eco-friendly and has continuously been further developed and improved.

Portfolio:

- Separation and cleaning of oil- and emulsion mist at machine tools

- Gathering and separation of sold-, weld- and oil smoke

- Dust- and chip suction

- Special applications, for example suction of plastic-, silicone- & releasing agent vapours

- Explosion- and fire protection at oil-cooled machine tools

- Suction at source, group suction, centralized air suction, hall air cleaning

- High-duty filter units, ventilation, heat recovery

- 24/7 Service with 15 support points in 11 countries

Available in independant or central suction plants, our equipments are used for exhaust air, air supply or hall air suction, purification. The plants are mounted as initial equipments on machines of well-known automotive manufacturers or as retrofits on already available machines of small and medium size enterprises.

Keywords:

Airfilter, suction-devices, electrofilter, emulsionmist-filter, oilmist-filter, dustfilter , chipfilter, welding-fume-filter, solder-smoke-filter, safety-technics, fire-protection, machine-tools

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Energy-Conserving Suction of Aerosols & Smoke at a Dörries Scharmann Machining Center here

News-ID: 154666 • Views: …

More Releases from LTA Lufttechnik GmbH

AC 6000 CIP – compact, automatically cleaning, long life

The AC 6000-CIP is an automatically cleanable air filter of compact design. Due to its special design, the air filter AC 6000-CIP is perfectly suited for direct machine integration. The aerosol-containing exhaust air flows through a double-stage electrostatic air filter. During this process, the particles (aerosols) contained in the air are charged, diverted by an electrical field between the collector plates and precipitated. The voltage…

Industrial Environmental Protection Through Energy Efficiency

In industrial applications, environmental protection often has to give way to commercial interests although both interests may be connected by means of targeted improvements in the fields of energy efficiency. This definitely makes sense not just for technical reasons but also since the number of norms and standards is rocketing upwards.

LTA pursues two strategies pertaining to the suction of machine tools in close cooperation with the machine and plant manufacturers.

For…

Bulk order received from Opel Szentgotthard, Hungary

LTA Industrial Air Cleaning has received a bulk order from Opel Szentgotthard (Hungary), for delivery of suction systems for two crankshaft-lines, three block- and two cylinder head lines in the engine production. While doing this the scope of supply from LTA contains the building of the total devices from the projecting, delivery, building site management, installation, start-up, training and measurements of the suction devices. The project comprises 11 high-duty filters…

Suction of Release Agents of Hot Forming Presses

Description of project & system:

On the 1st expansion level, an LTA air filter type AC 8002 with a suction output of approx. 10,000 m³ sucks the release agent vapors of 3 presses The aerosols are separated from the contaminated air and stick to the collector surface or condense partially and are drained towards the bottom. Once per day, the offline cleaning cycle is started. For this purpose, the system is…

More Releases for Alstom

The Continuing Growth Story of Railway Management System Market: Hitachi, ABB, A …

A Qualitative Research Study accomplished by HTF MI Title on Global Railway Management System Market has witnessed continuous growth in the past few years and is projected to grow even further during the forecast period (2019-2025). The assessment provides a 360 view and insights, outlining the key outcomes of the industry. These insights help the business decision-makers to formulate better business plans and make informed decisions for improved profitability. In…

Magnetic Resonance Imaging (MRI) Transport Market with top , Biodex, Newmatic Me …

"Magnetic Resonance Imaging (MRI) Transport Market research report delivers a close watch on leading competitors with strategic analysis, micro and macro market trend and scenarios, pricing analysis and a holistic overview of the market situations in the forecast period.

Get Exclusive FREE Sample Copy Of this Report @ https://www.upmarketresearch.com/home/requested_sample/24438

UpMarketResearch offers a latest published report on “Global Magnetic Resonance Imaging (MRI) Transport Market Analysis and Forecast 2019 - 2026” delivering key insights…

Substation Automation Market Touching Impressive Growth| ABB, Siemens, Alstom

HTF MI released a new market study on Global Substation Automation Market with 100+ market data Tables, Pie Chat, Graphs & Figures spread through Pages and easy to understand detailed analysis. At present, the market is developing its presence. The Research report presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates…

Bullet Train Market Is Booming Worldwide | Bombardier, Alstom

HTF MI released a new market study on Global Bullet Train Market with 100+ market data Tables, Pie Chat, Graphs & Figures spread through Pages and easy to understand detailed analysis. At present, the market is developing its presence. The Research report presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates…

Global Industrial Controls System Market Size, Status, Key Players: Honeywell, A …

Market Research Hub (MRH) has actively included a new research study titled “Global Industrial Controls System Market Size, Status and Forecast 2018-2025” to its wide online repository. The concerned market is discoursed based on a variety of market influential factors such as drivers, opportunities and restraints. This study tends to inform the readers about the current as well as future market scenarios extending up to the period until 2025. In…

Locomotives Market: CRRC, GE Transportation, Alstom, Siemens, Bombardier

MarketResearchReports.Biz announced the analysis report titled "Global Locomotives Market": Industry Analysis, Size, Share, Growth, Trends, and Forecasts.

This report studies the Locomotives market. Locomotive is a rail transport vehicle that provides the motive power for a train. Locomotives use electricity to drive forward motion despite some locomotive named 'diesel'. In diesel locomotive, a large diesel engine turns a shaft that drives a generator which makes electricity. This electrical energy powers large…