Press release

New solutions for safe electrostatic grounding in hazardous areas

Thanks to continuous monitoring of the earthing connection, grounding monitoring devices ensure safety in hazardous areas

The grounding monitoring devices are suitable for outdoor installation and can even be used in extreme climates (-50 °C to +60 °C). Both types are equipped with an IP65 housing. 8485 devices are designed for use in zone 1, while the 7485 series has been optimised for installation in zone 2 as well as zone 21 and 22 hazardous dust atmospheres. A two-channel version, i.e. a model with two earthing clamps, allows for efficient monitoring of combined loading units, e.g. trains and trucks. In that case, the monitoring mode can be individually adapted to the application for each of the two clamps. In addition to the corrosion-resistant earthing clamp with good contact pressure, the solution includes a robust, oil-resistant cable. The clamps are available with simple cables, spiral cables or an automatic retractor suitable for use in zone 1.

Company Background

For more than 80 years, R. STAHL has been a trendsetting manufacturer of safety technology for hazardous areas. Based in Waldenburg, Germany, the company is one of the world's leading suppliers of explosion-protected automation, control and distribution, installation, operating and monitoring, lighting, signaling and alarm components and systems. Key products include customer-specific systems solutions for hazardous areas. R. STAHL's individual packages containing tailored product combinations and a wide range of services such as consulting, project planning, engineering and training courses for customers are designed to fully meet application requirements and customer needs. International certifications, approvals and patents demonstrate the company's expertise and allow for R. STAHL's products to be used throughout the world.

Contact:

R. STAHL

Kerstin Wolf

Am Bahnhof 30

74638 Waldenburg

Germany

Tel.: +49 . 7942 . 943-4300

Fax: +49 . 7942 . 943-404 300

E-mail: kerstin.wolf@stahl.de

Internet: www.stahl.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release New solutions for safe electrostatic grounding in hazardous areas here

News-ID: 140191 • Views: …

More Releases from R. STAHL

Energy-efficient LED beacons from R. STAHL

In addition to tried-and-tested models with halogen and xenon flash lamps, R. STAHL's 6162 line of signal beacons now also includes energy-saving LED-based continuous beacons and rotating beacons. With little self-heating, these new models are suitable for use in Ex zones 1, 2, 21, and 22. They fulfill the requirements of temperature class T6 and surface temperature for dust explosions protection T80 °C, and come with an integrated "increased safety"…

Completely wireless switching devices for ATEX zones 1, 2, 21 and 22

R. STAHL's new 8074 F series position switches and 8040 F series command devices are truly, completely wireless solutions for radio signal communication. Requiring neither signal lines nor external energy supply connections, the units can be freely installed in zone 1, 2, 21, or 22 hazardous areas. Users therefore need not worry about any wiring when e.g. retrofitting the command devices into difficult-to-access machines or plants. Since there is no…

Modular UPS solutions for hazardous areas

R. STAHL provides uninterruptible power supplies for hazardous areas which ensure the safe operation of systems that require 100% availability. The UPS units are assembled from a modular design kit and can be optimally adapted to specific applications. They can be used to safely bridge complete blackouts or malfunctions in the mains power supply, such as frequency fluctuations or overvoltages caused by lightning strikes which can result in plant downtime.…

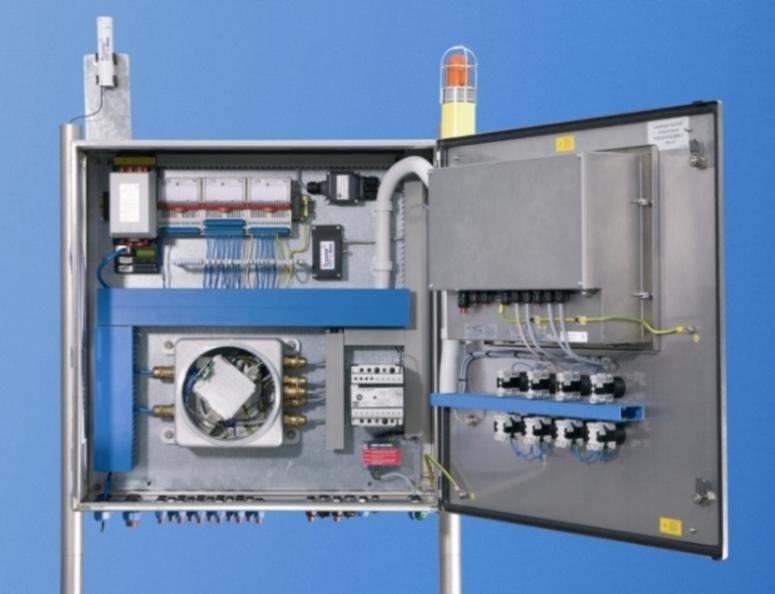

System solutions for explosion-protected equipment

A specialised supplier with decades of experience and comprehensive knowledge in explosion protection, R. STAHL has been providing users with system solutions for automation applications in hazardous areas for 30 years. Based on R. STAHL's products and, if required, specific third-party components, these solutions can be implemented quickly, reliably and at predictable, attractive prices. An R. STAHL system solution is a technology package from one source, delivered tested, certified and…

More Releases for Waldenburg

Safety Switch Market to Hit USD 2.04 Billion by 2030, Growing at 6% CAGR

Safety Switch Market size was valued at USD 1.4 Billion in 2023 and the total Safety Switch revenue is expected to grow at a CAGR of 6 % from 2024 to 2030, reaching nearly USD 2.04 Billion by 2030.

Safety Switch Market Overview:

The safety switch market comprises devices designed to protect personnel and equipment by quickly disconnecting electrical power in hazardous situations. These switches are widely used across industries such as…

Safety Switch Market to Reach USD 2.04 Billion by 2030, Growing at 6% CAGR

Safety Switch Market size was valued at USD 1.4 Billion in 2023 and the total Safety Switch revenue is expected to grow at a CAGR of 6 % from 2024 to 2030, reaching nearly USD 2.04 Billion by 2030.

Safety Switch Market Overview:

The Safety Switch Market is experiencing robust growth as industries and households increasingly prioritize safety and operational reliability. Safety switches are designed to immediately disconnect electrical power in hazardous…

Woody Auction's April 20th Art Glass, Lamps and Much More Auction Includes A Vam …

Douglass, KS, USA, April 9, 2024 -- A wide selection of quality antiques will come up for bid at an at Art Glass, Lamps and Much More auction planned for Saturday, April 20th, by Woody Auction, online (thru LiveAuctioneers.com) and live in the auction house located at 130 Third Street in Douglass. In total, 333 lots will cross the auction block, all with no reserves, beginning promptly at 9:30 am…

Energy-efficient LED beacons from R. STAHL

In addition to tried-and-tested models with halogen and xenon flash lamps, R. STAHL's 6162 line of signal beacons now also includes energy-saving LED-based continuous beacons and rotating beacons. With little self-heating, these new models are suitable for use in Ex zones 1, 2, 21, and 22. They fulfill the requirements of temperature class T6 and surface temperature for dust explosions protection T80 °C, and come with an integrated "increased safety"…

Completely wireless switching devices for ATEX zones 1, 2, 21 and 22

R. STAHL's new 8074 F series position switches and 8040 F series command devices are truly, completely wireless solutions for radio signal communication. Requiring neither signal lines nor external energy supply connections, the units can be freely installed in zone 1, 2, 21, or 22 hazardous areas. Users therefore need not worry about any wiring when e.g. retrofitting the command devices into difficult-to-access machines or plants. Since there is no…

Modular UPS solutions for hazardous areas

R. STAHL provides uninterruptible power supplies for hazardous areas which ensure the safe operation of systems that require 100% availability. The UPS units are assembled from a modular design kit and can be optimally adapted to specific applications. They can be used to safely bridge complete blackouts or malfunctions in the mains power supply, such as frequency fluctuations or overvoltages caused by lightning strikes which can result in plant downtime.…