Press release

Infrared Heat Increases the Up-Time of Gas Power Plant

Gas power plants, which supply electricity to meet peak demands, must work reliably and come on line rapidly, especially in the cold times of the year.For combustion, gas turbines need air which must be free from dust and other particles and, consequently, this is always pre-filtered. Cold and moist intake air in the winter months can easily lead to icing up of the filters. This means that less air is is passed through the filters so that the turbines must be choked or switched off – just when they are most needed.

At Trianel in Hamm, infrared systems from Heraeus Noblelight complement the de-icing protection in a modern combined cycle power plant (GuD). In just two weeks in May, 24 infrared modules, including controls, were installed and commissioned.

Modern combined cycle (gas and steam turbine) power plants generate electricity at a relatively high efficiency of around 60%, significantly higher than conventional power plants at around 40%. Moreover, they can be brought on line very quickly and so are used for handling medium and peak electricity load demands.

Electricity consumption is not steady but demand is in peaks and troughs. To meet this, fast acting power plants must be used. These can provide high power output within minutes. Gas power points offer such capability and they rely on being able to take in cleaned air. If the in-line filters become iced up, this can lead to power plant shut down. An efficient de-icing system, which above all must operate quickly and reliably, has to guarantee the availability of the power plant even in the cold winter months.

Trianel GmbH is a co-operative of 47 public utilities and operates a combined cycle power plant with two block unit power stations in Hamm. A coal-fired power station is under construction in Luenen and a further one is planned for Krefeld. An offshore wind farm is also underway in front of the island of Borkum. The combined cycle plant in Hamm is already several years old. The experience of the last two relatively hard winters caused Trianel to consider enhancing its existing anti-icing systems. Any solution had to be as easy as possible to retrofit and very responsive.

Thomas Kleinwaechter, manager of technical management and maintenance in Hamm, met with Heraeus Noblelight to investigate the suitability of electrical infrared systems for this application.

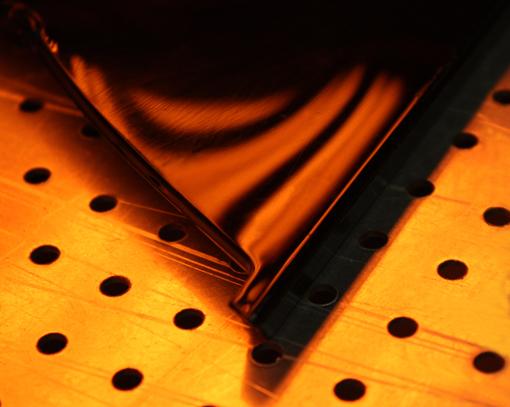

As with most gas power plants, the plant in Hamm used the “waste heat” from electricity generation for filter de-icing. This hot air is blown onto the pocket filters, made of fleecy material. However, there can be local cold and hot zones, especially when the hot air is not distributed sufficiently.

In contrast, infrared radiation has significant benefits. Energy is distributed without contact and generates heat within the material itself. In addition, infrared heat is rapidly available and heating is more energy-efficient than many conventional methods.

“I am convinced that infrared systems can heat the filters comprehensively and evenly without significantly impairing the cross-sectional flow of the intake air,” says Thomas Kleinwaechter. The power station operators also made the point that the de-icing enhancement system was a turnkey system which was supplied complete. “We were faced with a real challenge,” says Michael Lyhs, project manager at Heraeus Noblelight, “in the end, there was a window of just three weeks for the total electrical and mechanical installation and this work had to be carried out at heights of 11 to 25 metres.”

Altogether, surface areas of 8.8 x 4m were each fitted with 24 medium wave infrared emitters, with a total rated power of 236 kW. Every three of the 2.20m long emitters are mounted in a frame and these modules can be easily switched on and off and controlled by a switchboard or from the main control room. “The co-operation and collaboration between the power station staff and Heraeus worked so well that the system was up and running in just two weeks!” says Michael Lyhs, delightedly, “I am convinced that the de-icing system will meet the challenges of next winter perfectly.”

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico, is one of the technology and market leaders in the production of specialty light sources. In 2009, Heraeus Noblelight had an annual turnover of 71.6 Million € and employed 707 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with over 155 years of tradition. Our businesses include precious metals, sensors, biomaterials and medical products, dental products, quartz glass, and specialty light sources. With product revenues of € 2.6 billion and precious metal trading revenues of € 13.6 billion, as well as more than 12,300 employees in over 110 subsidiaries worldwide, Heraeus holds a leading position in its global markets.

Trianel

The liberalised energy market offers public utilities a wide range of opportunities. As the largest European Public Utility Co-operative with 47 members in Germany and the rest of Europe, Trianel has maximised this potential by means of innovative concepts along the total value and supply chain. At the same time, the network of utilities has made possible what would not have been possible for the individual utilities alone – from energy generation in highly efficient power stations through energy trading in our own trading floor up to the development of a broad palette of procurement and marketing solutions.

Trianel also sees future fields of activity for utilities in the areas of re-municipalisation and the use of electric-powered vehicles and is working to develop appropriate solutions with its partners. With its various activities, Trianel represents over 5 million customers.

Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Germany

Press: Dr. Marie-Luise Bopp

marie-luise.bopp@heraeus.com

www.heraeus-noblelight.com/infrared

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Infrared Heat Increases the Up-Time of Gas Power Plant here

News-ID: 139584 • Views: …

More Releases from Heraeus Noblelight

Infrared Heating helps to ensure quality in the manufacture of composite structu …

An infrared heating system from Heraeus Noblelight is helping to ensure the high quality of composite aerospace structures manufactured at the new GKN Aerospace facility at Western Approach, near Bristol. The system, which is used to provide interim processing of the laid-up composite rear spar assembly of the Airbus 350 XWB to prevent subsequent wrinkling, was custom-designed and developed in close co-operation with GKN Aerospace engineers following initial tests at…

Seven Good Reasons for the D2plus Light module

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources will again exhibit at ANALYTICA, to be held in Munich, Germany in April 2012. Heraeus will introduce its “Seven Good Reasons for D2plus Light modules” at the show, making the life of instrument developers easier.

Developing new analytical instruments places ever-increasing demands on engineers, to design-in the best available light-source and avoid future operational problems.…

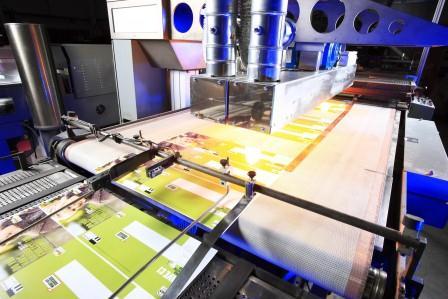

Specialty Light Sources for the Printing Industry

Hanau, February 2012

The Competence in Specialty Light Sources for printing systems

Special and personalized printing processes need special treatment. The ink of ink jet or laser printers need to be completely dried or cured before the printed sheets are passed on for subsequent operations such as stacking, cutting, folding or gluing. Infrared or UV technology is used for drying and curing, depending on the type of ink. Heraeus Noblelight presents its…

Infrared Emitters Improve Lacquered Surfaces

Many screens, internal claddings in cars and high value cosmetic packages are manufactured from plastics and contain a protective lacquer or finishing. The drying of the coating on the plastic components is not a trivial matter, for the surfaces need to be perfectly cured without applying to much heat to the plastic. Infrared heaters transfer energy in a contact-free manner and are easy to control. Consequently, the heat is precisely…

More Releases for Trianel

Medium Voltage Cables Market Development, Current Analysis and Estimated Forecas …

Global Medium Voltage Cables Market Projected to Grow due to Increasing Demand for Renewable Energy

For distribution of power in industrial settings, medium-voltage cables are used in mobile substation equipment, to supply power to drills in mining, shovels, and haulers. Medium voltage cable provides a reliable power source in the event of unpredictable power outage situations, power distribution to isolated areas and any application ranging from 5kV up to 35Kv. Increase…

Offshore Wind Turbine Market 2020 Global Insights and Business Scenario – ADWE …

The Offshore Wind Turbine Market report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides an in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies. We analyzed…

Deutsche Windtechnik takes over all offshore maintenance contracts from Dutch co …

Bremen, 02.03.2016

Deutsche Windtechnik AG has finalised an asset deal with the listed construction company Ballast Nedam N.V.; with immediate effect, the foundations and cables for the offshore wind farms Westermeerwind in the IJsselmeer and Butendiek, Luchterduinen and Prinses Amalia Wind Farm in the North Sea will be maintained by Deutsche Windtechnik. The company is also taking on the civil engineers from Ballast Nedam responsible for parts of the project management…