Press release

Safety Technology

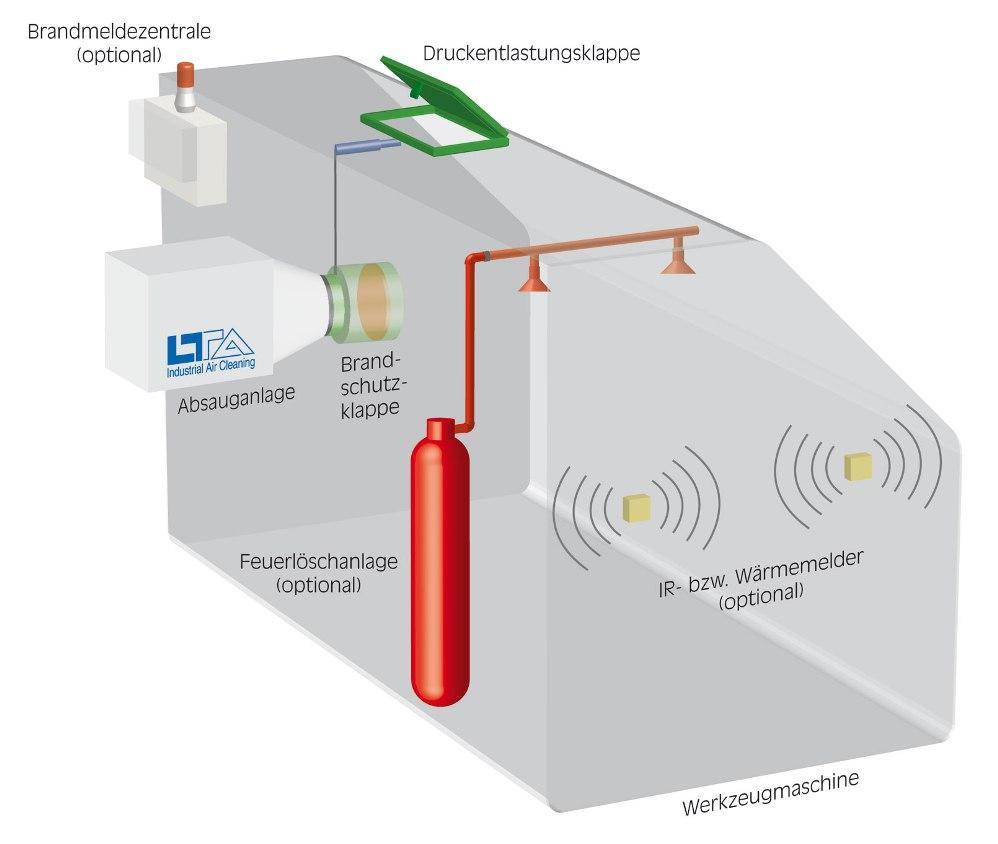

In the metal-working industry, large quantities of cooling lubricant are used especially in cutting processes. These cooling lubricants predominantly are non water-soluble oils having the characteristic to form explosive mixtures with air. Heating them up above their flashing point produces explosive vapor/air mixtures. This can be prevented by selecting cooling lubricants with a rather high flashing point. However, the formation of aerosols due to atomizing or spraying processes cannot be averted. Such aerosols are explosive even below the flashing point. When using oil/water emulsions (water-soluble cooling lubricants), a water contents of 80% is required to reliably exclude an ignition.There are number of countermeasures increasing the safety when applying non water-soluble cooling lubricants in machine tools. Messrs. LTA Lufttechnik GmbH from Nordrach has developed a special fire and explosion protection system which was appraised by an independent institute (IBEXU). This system comprises a pressure relief flap, a trip unit and a fire protection flap.

The LTA pressure relief flap protects the machine housing against deformation which would result from the increased pressure generated by an explosion. If a predefined overpressure is detected in the machine, a pressure relief valve opens. This opens an orifice through which the overpressure may escape. After the escape of the overpressure, the pressure relief flap is automatically opened again. As opposed to other systems, this flap can be reused as often as required. The opening pressure may exactly be defined and also the flap position is easy to monitor.

The LTA trip unit forms the connecting link between pressure relief flap and fire relief flap or controls the function of the fire protection flap via other signals (e.g. fire detector, UV sensor etc.). The triggering is selective where factors like reaction time, operator friendliness, monitoring time and reliability must be taken into consideration.

The LTA fire protection flap serves to interrupt the connection between suction and machine in case of a fire or an explosion. This prevents the stoking of the fire due to the following sucked fresh air and the flames from jumping over to the suction system and the piping systems.

LTA Lufttechnik is a renowned partner for complete solutions in air technology. The company projects, builds and delivers air filter and fire protection systems for trade and industry. For over 30 years, LTA has been researching, developing and manufacturing aerosol separation products. The electrostatic separation method is eco-friendly and has continuously been further developed and improved.

Portfolio:

- Separation and cleaning of oil- and emulsion mist at machine tools

- Gathering and separation of sold-, weld- and oil smoke

- Dust- and chip suction

- Special applications, for example suction of plastic-, silicone- & releasing agent vapours

- Explosion- and fire protection at oil-cooled machine tools

- Suction at source, group suction, centralized air suction, hall air cleaning

- High-duty filter units, ventilation, heat recovery

- 24/7 Service with 15 support points in 11 countries

Available in independant or central suction plants, our equipments are used for exhaust air, air supply or hall air suction, purification. The plants are mounted as initial equipments on machines of well-known automotive manufacturers or as retrofits on already available machines of small and medium size enterprises.

Keywords: Airfilter, suction-devices, electrofilter, emulsionmist-filter, oilmist-filter, dustfilter , chipfilter, welding-fume-filter, solder-smoke-filter, safety-technics, fire-protection, machine-tools

LTA Lufttechnik GmbH

Junkerstraße 2

D - 77787 Nordrach

Tel.: +49/7838/84-245

Fax: +49/7838/84-308

Email: info@lta.de

Homepage: www.lta.de

press contact:

Philipp Fehrenbach

sales office-duty and marketing-manager

Tel.: +49/7838/84-331 (Fax: -308)

Email: philipp.fehrenbach@lta.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Safety Technology here

News-ID: 131380 • Views: …

More Releases from LTA Lufttechnik GmbH

AC 6000 CIP – compact, automatically cleaning, long life

The AC 6000-CIP is an automatically cleanable air filter of compact design. Due to its special design, the air filter AC 6000-CIP is perfectly suited for direct machine integration. The aerosol-containing exhaust air flows through a double-stage electrostatic air filter. During this process, the particles (aerosols) contained in the air are charged, diverted by an electrical field between the collector plates and precipitated. The voltage…

Industrial Environmental Protection Through Energy Efficiency

In industrial applications, environmental protection often has to give way to commercial interests although both interests may be connected by means of targeted improvements in the fields of energy efficiency. This definitely makes sense not just for technical reasons but also since the number of norms and standards is rocketing upwards.

LTA pursues two strategies pertaining to the suction of machine tools in close cooperation with the machine and plant manufacturers.

For…

Bulk order received from Opel Szentgotthard, Hungary

LTA Industrial Air Cleaning has received a bulk order from Opel Szentgotthard (Hungary), for delivery of suction systems for two crankshaft-lines, three block- and two cylinder head lines in the engine production. While doing this the scope of supply from LTA contains the building of the total devices from the projecting, delivery, building site management, installation, start-up, training and measurements of the suction devices. The project comprises 11 high-duty filters…

Energy-Conserving Suction of Aerosols & Smoke at a Dörries Scharmann Machining …

The Alstom Power Service company in Berlin is active in service, maintenance & repair of turbines for power generation. At a Dörries Scharmann machining center, a lot of emulsion mist and smoke escaping through the not 100% capsuled machine cover is produced during the turning/milling processes due to the large size of the parts. It was LTA's task to prevent just that. An LTA air filter type AC 3061 was…

More Releases for Nordrach

AC 6000 CIP – compact, automatically cleaning, long life

The AC 6000-CIP is an automatically cleanable air filter of compact design. Due to its special design, the air filter AC 6000-CIP is perfectly suited for direct machine integration. The aerosol-containing exhaust air flows through a double-stage electrostatic air filter. During this process, the particles (aerosols) contained in the air are charged, diverted by an electrical field between the collector plates and precipitated. The voltage…

Industrial Environmental Protection Through Energy Efficiency

In industrial applications, environmental protection often has to give way to commercial interests although both interests may be connected by means of targeted improvements in the fields of energy efficiency. This definitely makes sense not just for technical reasons but also since the number of norms and standards is rocketing upwards.

LTA pursues two strategies pertaining to the suction of machine tools in close cooperation with the machine and plant manufacturers.

For…

Bulk order received from Opel Szentgotthard, Hungary

LTA Industrial Air Cleaning has received a bulk order from Opel Szentgotthard (Hungary), for delivery of suction systems for two crankshaft-lines, three block- and two cylinder head lines in the engine production. While doing this the scope of supply from LTA contains the building of the total devices from the projecting, delivery, building site management, installation, start-up, training and measurements of the suction devices. The project comprises 11 high-duty filters…

Small, compact, cheap - the new airfilter AC 500 of LTA!

The new filter AC 500 marks through its ultra-compact design. This compactfilter can be mounted directly on the machine, the recirculation of the separated medium happens directly in the machine, too.

As its “big brother” of the series AC 3000 are the pre-filter integrated in the housing. The advantage for the customer are the completely washable filter-cells – no throw away filter!

The filter cells are constructed universal and as well for…

Automatic Cleaning - New Cleaning System by LTA

The large modules starting from the type AC 800X size versions may now optionally be equipped with an innovative cleaning system. With this system, the individual filter levels are cleaned via installed nozzle fittings with appropriate full-cone nozzles. Such cleaning may only be made with the system stopped so that the logical interconnection with the production line must be taken into account. In order to minimize any carry-over of the…

New LTA-airfilter AC 8000 – Big power on small space

The solution for group- or centralsuctions

The new filter AC 8000 marks through its robust construction.

It provides as optimal solution for group- and central-suction of oil- and emulsion-mist at machines and machining centers or whole factory buildings.

By its modular construction it can be custom-made on all needs.

As all filters from LTA are the pre-filters integrated in the housing. Further advantage for the customers are the completely washable filtercells –…