Press release

Automated container-type Rotainer pickling systems

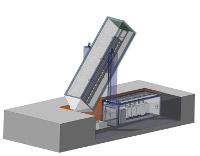

Braunschweig/Germany, 05 September 2018 – At EuroBLECH, the German company Siedentop will be showcasing its EU-patented systems for stainless steel pickling. These Rotainer pickling systems are computer controlled, which improves the pickling result while also saving resources. The systems are designed as closed containers and are emission-free.Pickling is an essential process, yet it remains an inconvenient issue for many stainless steel processing companies. It is said to be toxic, environmentally hazardous, subject to tight restrictions as well as expensive. While these shortcomings do apply to traditional bath and spray pickling, modern pickling systems using the Rotainer principle avoid them entirely.

Siedentop’s Rotainer pickling systems are built as closed containers so that no toxic gases may escape into the ambient air. Consequently, there is no need for evacuation and cleaning of the air, which is a common obligation when applying conventional pickling methods.

Siedentop’s Rotainer system uses nozzles to spray bath pickling acid on the stainless steel parts to be processed. Even complicated surfaces and cavities are treated perfectly. Every processing step – from degreasing to pickling, passivation, rinsing, and air washing – are carried out as a fully automated programme. The computer-controlled pickling process saves time and ensures consistently high pickling quality. At the same time, the Rotainer pickling principle reduces the quantity of pickling agent. It requires a maximum of 900 litres of pickling agent. The Rotainer principle is also leading in terms of accident prevention: the Siedentop system works with nitric acid-free pickling acid. Operators do not come in contact with acid during the pickling process.

Siedentop will be presenting the Rotainer pickling system at the EuroBLECH exhibition in Hall 13 at Stand H141. EuroBLECH will be held from 23 to 26 October 2018 in Hanover. It is the world’s largest exhibition for the sheet metal working industry.

Siedentop GmbH, a family-run company, is based in Braunschweig (Germany) and has been developing and producing environmentally sound and resource-saving pickling systems for the metalworking industry since 1986. The technology of the EU-patented Rotainer pickling system has been nominated for the German Environmental Award and the Grand Prize for Small and Medium-sized Companies. In addition, Siedentop has also won the “Best of” category in the INDUSTRIEPREIS award for "companies with a high economic, social, technological, and ecological benefit".

Siedentop GmbH distributes the effluent- and emission-free Rotainer pickling systems. For more information, please visit www.top-beizen.com.

Siedentop GmbH

Stainless Steel Surface Technology

Neckarstrasse 9

D-38120 Braunschweig

Phone: +49 (0)531- 88 93 93 0

anfrage@top-beizen.de

www.top-beizen.com

PR-Agency:

frische denke

Jutta Thiel

Jasperallee 71

D-38102 Braunschweig

Phone: +49 (0)531- 472 152 60

www.frischedenke.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automated container-type Rotainer pickling systems here

News-ID: 1221371 • Views: …

More Releases from Siedentop GmbH

No legal approval necessary: PLC-controlled pickling system for long stainless s …

Braunschweig/Germany, 23 October 2018 – A true novelty debuts at the international sheet metal working exhibition EuroBLECH: The German company Siedentop GmbH presents a pioneering pickling system for long stainless steel tubes that may be installed without prior legal approval in most countries. It is a cost-effective alternative to conventional tube pickling and offers resource-saving and fast pickling processes.

The fully automated tube pickling system Tube Blue Rotainer is built as…

More Releases for Rotainer

No legal approval necessary: PLC-controlled pickling system for long stainless s …

Braunschweig/Germany, 23 October 2018 – A true novelty debuts at the international sheet metal working exhibition EuroBLECH: The German company Siedentop GmbH presents a pioneering pickling system for long stainless steel tubes that may be installed without prior legal approval in most countries. It is a cost-effective alternative to conventional tube pickling and offers resource-saving and fast pickling processes.

The fully automated tube pickling system Tube Blue Rotainer is built as…