Press release

On-Chip 3D Microprinting for Photonic and MEMS Systems: Additive manufacturing of micro-parts on integrated circuits saves packaging costs and time

Growing demands on high-speed data communication, unmanned aerial vehicles and portable medical devices are attracting industries to new manufacturing methods like, for example, Nanoscribe’s direct laser writing technology. Currently, the production of photonic circuits and microelectromechanical systems (MEMS) needed for these applications requires different manufacturing methods and multiple process steps for bringing together various components on one microchip. Now, with Nanoscribe’s highest resolution 3D printers one can print and integrate microscopic components directly on integrated circuits such as micro-lenses onto photonic circuits and deformable structures on microelectromechanical systems (MEMS) actuators. With this groundbreaking technique smallest objects with complex geometry and feature sizes from hundreds of nanometers up to several millimeters can be printed. They are produced in a single printing step and on a scale which was inaccessible to 3D printing before. This major update of on-chip printing brings new perspectives for producing nano- and microscale 3D components in situ, exactly where needed.For this 3D printing process, Nanoscribe’s Photonic Professional GT system uses the method of two-photon polymerization. The precision optics and advanced software tools of this 3D printer allow to fabricate 3D polymer structures with submicron precision, making the strengths of additive manufacturing available to micro- and nanofabrication. These advantages are the full 3D design freedom and a simple workflow from CAD model to final part resulting in rapid design iteration cycles that save time and costs during product development. Additionally, the wide choice of print surfaces now also includes pre-patterned chips making miniaturization of 3D functional parts into highly integrated circuits possible.

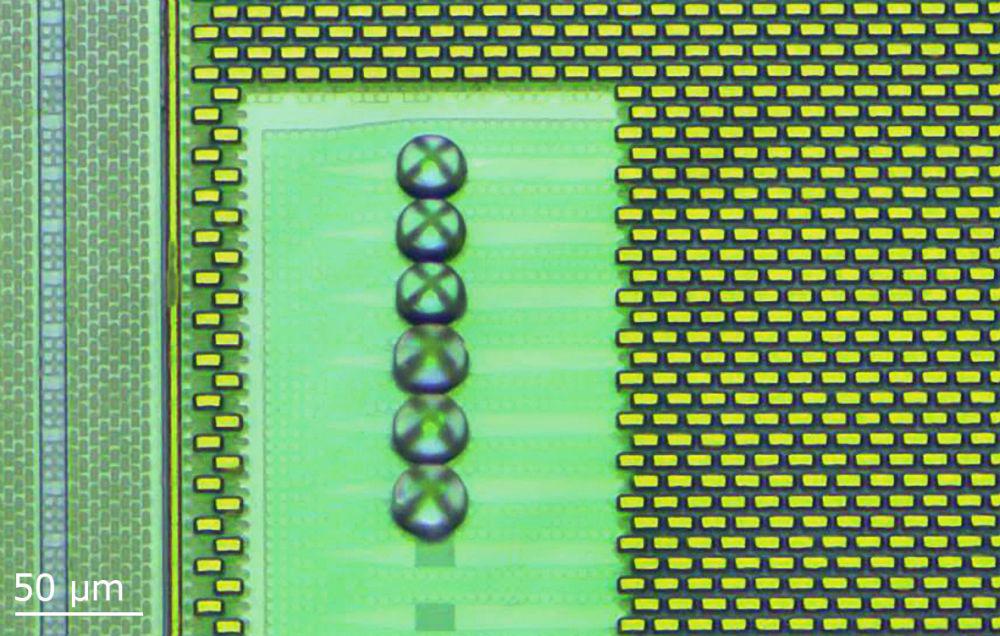

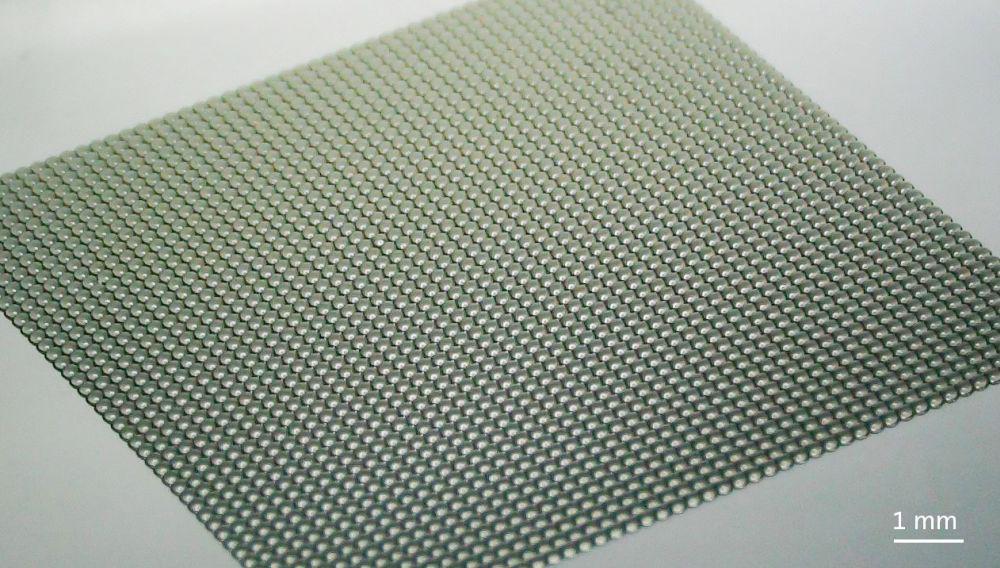

In the attached movie Nanoscribe demonstrates the printing of micro-lenses onto photonic chips for the first time (Img 1). A series of hemispherical micro-lenses were fabricated on top of grating couplers previously patterned on a photonic chip (Img 2). This way, an array of micro-lenses can couple light into the circuit. The micro-optics were created in one printing step and without the need to align and mount the finished micro-optics mechanically into the pre-structured microchip. This process of direct fabrication of components onto existing circuits reduces packaging costs in equipment and saves time in calibration. Moreover, it avoids pick and place as well as curing-based fixing procedures. Taking advantage of the laser accuracy, 3D microprinting also offers submicron precision and optical quality surfaces meeting the requirements for high performance micro-optics. Altogether, these benefits make this manufacturing technique a valuable method for in situ fabrication of micro-optics onto photonic integrated circuits for higher data transfer in telecommunication.

3D printed micromechanical components on MEMS actuators

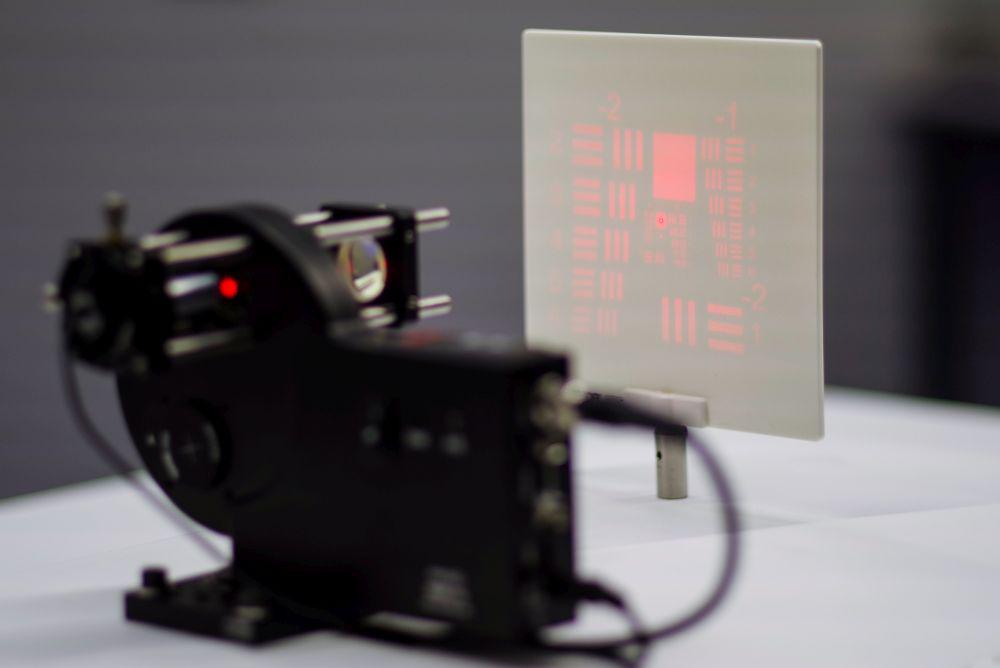

Applications in medical imaging, tissue regeneration and MEMS actuators can benefit from the fabrication of integrated circuits. For example, Nanoscribe customers at the Boston University, headed by Professor Alice White, fabricated 3D deformable bowtie-like structures directly on MEMS actuators (Img 3). The 3D printed micromechanical bowties are structures that stretch and deform in 3D due to their geometry. The scientists were able to deform the microstructure by applying a voltage to the MEMS actuator. Professor White states: “We show that coupling 3D microprinting with MEMS actuators is a powerful way to produce 3D micromechanical systems tailored to specific needs. Nanoscribe 3D printers allow us rapid prototyping of submicron-resolution structures that would otherwise be impossible to fabricate via single-photon stereo-lithography or the deposition and etching processes commonly used in semiconductor foundries.” Their results will potentially find applications based on the dynamic actuation of 3D printed microstructures such as deformable optics and scaffolds for tissue engineering.

The integration of microscopic components into photonic and MEMS systems is one of today’s challenges in manufacturing and packaging. Together with this kind of miniaturization more and more functional parts have to be accommodated in ever smaller spaces. Solving this challenge with the use of advanced 3D microfabrication tools will open the way to commercial applications from high-speed data transfer and telecommunication to mobile devices for healthcare.

Technology behind on-chip 3D printing

The two-photon polymerization process is the basis for Nanoscribe’s 3D microprinting technology. In this printing process a laser exposes a photosensitive resin by means of a high-numerical aperture objective in a controlled trajectory and layer-by-layer following a CAD design. The material solidifies only in the laser focus spot allowing for nearly 3D arbitrary structures with even submicron features. The new update of this technique expands the scope of use for printing on pre-manufactured circuits and opens new avenues for on-chip printing.

Movie: https://www.youtube.com/watch?v=ZHY8kS3CZ7g

About Nanoscribe

The supplier of 3D printers for nano- and microfabrication has established itself as technology and global market leader with its laser lithographic processes. Based on the technique of two-photon polymerization, the Photonic Professional GT systems enable the fabrication of highest-resolution and ultra-complex 2D, 2.5D, and 3D nano- and microstructures for scientific and industrial applications. Renowned universities and top research institutes use the award-winning systems in more than 30 countries. Nanoscribe´s portfolio is complemented by tailor-made resins and process solutions. The medium-sized company was founded in 2007 as a spin-off from the Karlsruhe Institute of Technology (KIT).

Nanoscribe GmbH

Media Contact

Anke Werner

Hermann-von-Helmholtz-Platz 1

DE-76344 Eggenstein-Leopoldshafen

Germany

Phone: +49 (0)721 981 980 501

E-Mail: werner@nanoscribe.com

www.nanoscribe.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release On-Chip 3D Microprinting for Photonic and MEMS Systems: Additive manufacturing of micro-parts on integrated circuits saves packaging costs and time here

News-ID: 1117817 • Views: …

More Releases from Nanoscribe GmbH

Ultra-Precise Additive Manufacturing Enables Serial Production of Micro-Optics

Nanoscribe showcases production processes from 3D printed polymer masters to series replication at SPIE Photonics West 2019

Nanoscribe’s new Photonic Professional GT2 3D printers change the way to produce micro-optical components. This additive manufacturing technology enables the fabrication of ultra-precise micro-optics as polymer masters for serial production, which are needed, for instance, in mobile or augmented reality devices, for sophisticated sensors or advanced solutions in healthcare and automotive industry.

At the upcoming…

Photonic Professional GT2 Prints Diffractive Optical Elements with Submicron Pre …

Nanoscribe presents additively manufactured multi-level DOEs at SPIE Photonics West 2019

At the upcoming Photonics West 2019, the prestigious trade fair for optics and photonics taking place in San Francisco, Nanoscribe showcases multi-level diffractive optical elements (DOEs) that are fabricated by means of high resolution 3D printers Photonic Professional GT2 (Nanoscribe, booth 366, South Hall).

The fabrication of multi-level DOE microstructures gains more and more attention, both in scientific research as well…

Ultra-Precise 3D Printing Can Help Drug Testing for Treating Brain Disorders

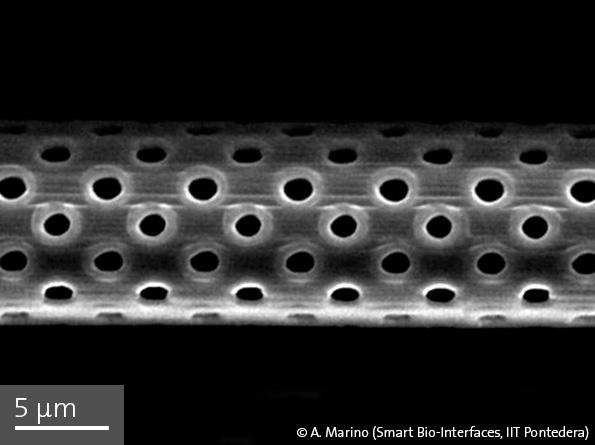

Following you will find pioneering research results from the IIT - Istituto Italiano di Tecnologia (Italian Institute of Technology) recently highlighted on the inside cover of the well-known scientific journal Small:

Researchers of the Smart Bio Interfaces group at the IIT in Pontedera (Pisa, Italy) created the first biohybrid device mimicking the blood-brain barrier by means of a Nanoscribe 3D printer. The understanding of the blood-brain barrier mechanisms is target of…

More Releases for MEMS

Motion Sensor Market By Types - MEMS Magnetometer, MEMS Accelerometer, MEMS Gyro …

Motion sensing is a rising technology that is transforming the way equipment interacts with machines and humans in the form of detection. Motion sensor is not only used in business and infotainment applications but also in routine activities in homes and other settings.

The global motion sensor market is primarily driven by factors such as increasing application of motion sensors in automotive industry and consumer electronics industry. Motion sensors in the…

Automotive MEMS Sensor

The Insight Partners added “Laser Technology Market to 2025” to its research database. The report is spread across 150 pages and supported by 10 company leaders.

A laser is a coherent and focused beam of photons; coherent, in this context, means that it is all one wavelength, unlike ordinary light which showers on us in many wavelengths. Laser technology is used for an extensive range of professional field measurement applications which…

Bio-MEMS Market - Uptake of Microfluidics for Diagnostics Improves Adoption of B …

Transparency Market Research has observed the competitive landscape in the global bio-MEMS market to be quite consolidated. The top five players held a whopping share of about 45% in the global market in 2015. Abbott Laboratories, Becton Dickinson, Baxter International Inc., Medtronic, and Boston Scientific have been dominating the global market with their persistent efforts to develop innovative products and continuous research and development to enhance their existing product portfolio.…

Global RF-MEMS Market 2017 : DelfMEMS, MEMtronics, Radant MEMS, WiSpry, Cavendis …

A market study based on the "RF-MEMS Market" across the globe, recently added to the repository of Market Research, is titled ‘Global RF-MEMS Market 2017’. The research report analyses the historical as well as present performance of the worldwide RF-MEMS industry, and makes predictions on the future status of RF-MEMS market on the basis of this analysis.

Get Free Sample Copy of Report Here :

http://bit.ly/2qj78sg

Top Manufacturers Analysis Of This Research…

Bio MEMS Market - Cardio-MEMS to Lead, North America to Remain Frontrunner

Transparency Market Research has observed the competitive landscape in the global bio-MEMS market to be quite consolidated. The top five players held a whopping share of about 45% in the global market in 2015. Abbott Laboratories, Becton Dickinson, Baxter International Inc., Medtronic, and Boston Scientific have been dominating the global market with their persistent efforts to develop innovative products and continuous research and development to enhance their existing product portfolio.…

Bio MEMS Market: High Prevalence of Heart Diseases Gives Impetus to Cardio-MEMS

Transparency Market Research has observed the competitive landscape in the global bio-MEMS market to be quite consolidated. The top five players held a whopping share of about 45% in the global market in 2015. Abbott Laboratories, Becton Dickinson, Baxter International Inc., Medtronic, and Boston Scientific have been dominating the global market with their persistent efforts to develop innovative products and continuous research and development to enhance their existing product portfolio.…