Press release

Partial automation from Storopack for the packaging station: Air-cushions arrive just at the right time

The new machine model, the Airplus BagSeparator makes it possible to supply a sensor-controlled machine with up to 24 packaging stations using air-cushions. Employees remove the cushions from the silos, which are placed in an ergonomically favourable posi

In order to achieve and maintain a constant high level of output, it is necessary in the opinion of the company to look at the work place layout and the job ergonomics more closely. These two aspects hold a high potential for increased productivity. Storopack integrates this task into the concept of “working comfort” and makes it a part of the consulting approach.

Advisers from Storopack gather details of the needs of the customer and examine the local conditions. Based on this, an optimal spatial arrangement and efficient operational processes are developed. The result is a solution, which fits best in the performance environment of current, automated distribution logistics. The technical prerequisites for this offering from Storopack are the new Airplus BagSeparator for production of air-cushions and a customised programmed control module. The latter controls the production of the cushions and their distribution into the silos via a flat conductor with electrically propelled flaps.

The Airplus BagSeparator system processes all film formats available from Storopack. The running speed is up to 10.5 m/minute. This corresponds to approx. 400 standard cartons each with 8.5 litres of filling material per hour with an air-cushion format of 200 x 120 mm. Important parameters can be adapted during the operation to meet current needs. In addition, the length of the individual padding strips is also important, and can be freely selected from between 1 and 99 cushions.

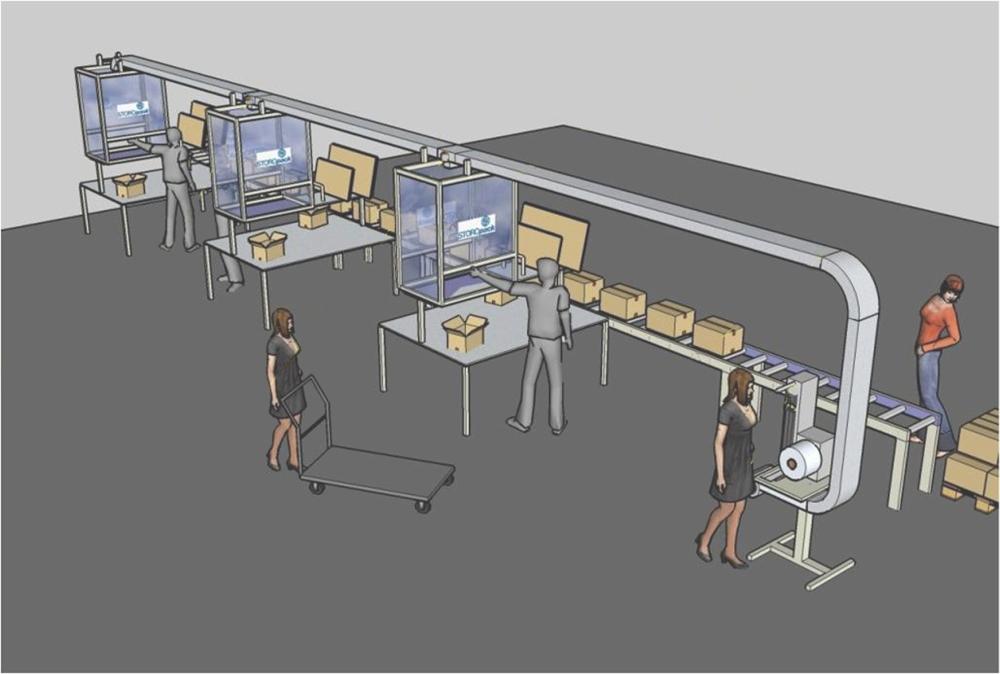

The machine is suitable both for equipping single place solutions as well as for supplying more than one packing station. Work is organised either inline, i.e. using a conveyor belt-like system, or at off-line packing tables. In order to supply several places, the Airplus BagSeparator feeds air-cushions to a flat channel. Flaps in the channel control the supply to the outgoing silos. A sensor in the silo gives the filling level as information to a programmable controller. This adjusts the status of the flaps. The system takes priorities into consideration, so that individual packing stations are preferentially supplied, if necessary. In order to meet higher demands with so-called speed lines, several devices can supply a single silo.

The kind of silo construction used depends on the spatial possibilities. Free-standing, self-supporting models are nearly always used. The access openings are arranged so that they make sense individually and ergonomically for the packers. In off-line procedures, so-called packing islands have proven an optimal form of organisation for workplaces: Two or four packing stations, in both cases facing one another, are placed on either side of the conveyor.

With the optimal calibration of all components, any manual work which is required at the packing station can be reduced to a minimum. Employees place a delivery note or other shipping documents on top of the goods, as necessary. They take air cushions out of the silo and fill cavities in the package before the cartons are automatically or manually closed.

This customised equipment can be rented or purchased. As the plant is of a modular design, it can be easily adapted to any changes in the circumstances at the logistics centre of the customer. Delivery takes place within six weeks after the order is placed. The installation can normally be assembled within 24 hours.

Text length: approx. 3,945 characters

Contact media/ press:

Schott Relations GmbH

Lindenspürstraße 22, 70176 Stuttgart, Germany

Tel. + 49 711 / 16446-16, Fax: + 49 711 / 16446-11

info@schott-relations.com

Storopack is a leading manufacturer and service provider in the fields of protective and transport packaging as well as molded parts made of expanded foams. The sales of the worldwide operating group of companies with headquarters in Metzingen (Germany) are generated by the three divisions Molding, Packaging and Logistics. The Packaging Division specialises in the “interior cushioning” market and covers the customised integration of complete packing lines for flowable cushioning materials (loose fill), air cushions, paper padding, and foam packaging systems. To supplement these interior and protective packaging, Storopack also provides service and technical advice on all packaging questions to manufacturing and trading companies in Germany, Belgium, and Switzerland and supplies a wide range of products in the field of transport packaging.

Storopack

Hans Reichenecker GmbH

Untere Rietstrasse 30

72555 Metzingen

Germany

Telephone +49 (0)7123 164 227

Fax +49 (0)7123 164 49 227

press@storopack.com

www.storopack.com

Commissioned with Public Relations Work:

Schott Relations GmbH

P.O. Box 104663

70041 Stuttgart

Germany

Telephone +49 (0)711 164 46 16

Fax +49 (0)711 164 46 11

info@schott-relations.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Partial automation from Storopack for the packaging station: Air-cushions arrive just at the right time here

News-ID: 79601 • Views: …

More Releases from Storopack Hans Reichenecker GmbH

Storopack: New location in India

In Pune, India, Storopack is establishing its own location. This move is part of the company strategy to get a foothold in developing markets. The protective packaging specialist already has renowned national and international clients with subsidiaries in India. „The Indian economy is at a turning point. Market participants need to increase their competitiveness in order to keep pace with the huge development. This includes a professional protective packaging solution,…

Electrostatic dissipating film versions of AIRplus® and FOAMplus® - Filling an …

Metzingen. The air-cushioning materials AIRplus® and FOAMplus® foam padding from Storopack are now available in an ESD film version for the protective packaging of electronic components. The film complies with the requirements of DIN EN 61340-5-1 for electrostatic dissipating materials. It has been developed by Storopack and is now manufactured from several of its production sites. The on-demand protective packaging systems are a practical alternative to normal ready-to-use packaging, such…

AIRmove® from Storopack: A contemporary look and refreshing concept for packagi …

Metzingen. The air-cushioning system AIRmove® from Storopack simplifies packaging for businesses that pack 100 or fewer cartons per day. It replaces multiple ready-to-use padding and filling products with a single universal packaging material that is produced on-demand. Companies will see their return on investment with as few as six packages per day. Storopack is marketing the system exclusively through authorized trading partners. The market introduction will be accompanied by the…

Success for PAPERplus®: Storopack Asia equips Kone Elevator India with paper pa …

Hong Kong. The elevator and escalator manufacturer Kone has been a customer of Storopack Asia since early 2011. The Indian subsidiary Kone Elevator India Pvt. Ltd. packs elevator doors and replacement parts at the production site in Chennai, India, using the paper padding system PAPERplus® GE. Storopack has supplied four devices of the Classic PAPERplus® Series via an Indian trading partner to Chennai. Kone appreciates the ease and reliability of…

More Releases for Airplus

FinTech Global Market 2021: Key Players – Air Canada, AirPlus International Lt …

United States/WA: The "Global FinTech Industry market Size, Status, and Forecast 2027" study from CMI provides an overview of the global FinTech Industry market. This section illuminates the primary impact-rendering factors and restrictions limiting expansion. It enables people to comprehend various flaws and how they may obstruct future growth. This section is one of the most important in the report since it explains how many macro and microeconomic factors affect…

Commercial/Corporate Card Market Is Booming Worldwide with Citigroup, Wex, AirPl …

Latest Report Available at Advance Market Analytics, “Commercial/Corporate Card Market” provides pin-point analysis for changing competitive dynamics and a forward looking perspective on different factors driving or restraining industry growth.

The global Commercial/Corporate Card market focuses on encompassing major statistical evidence for the Commercial/Corporate Card industry as it offers our readers a value addition on guiding them in encountering the obstacles surrounding the market. A comprehensive addition of several factors such…

Commercial or Corporate Card Market World's Top Players Include AirPlus Internat …

Commercial or corporate card is a credit card issued by employers for their employees to make purchases on behalf of the company. Commercial card is generally issued by a retailer and bears the name of both retailer and Credit Card Company. Commercial cards are frequently used by companies to keep track of expenses in order to analyze more closely the effects on the company budget. Commercial cards for business include…

Commercial or Corporate Card Market Worldwide Top Players Revenue Analysis of Ai …

Commercial or corporate card is a credit card issued by employers for their employees to make purchases on behalf of the company. Commercial card is generally issued by a retailer and bears the name of both retailer and Credit Card Company. Commercial cards are frequently used by companies to keep track of expenses in order to analyze more closely the effects on the company budget. Commercial cards for business include…

Electrostatic dissipating film versions of AIRplus® and FOAMplus® - Filling an …

Metzingen. The air-cushioning materials AIRplus® and FOAMplus® foam padding from Storopack are now available in an ESD film version for the protective packaging of electronic components. The film complies with the requirements of DIN EN 61340-5-1 for electrostatic dissipating materials. It has been developed by Storopack and is now manufactured from several of its production sites. The on-demand protective packaging systems are a practical alternative to normal ready-to-use packaging, such…

Airplus Autofeed for high-speed inline packing stations: Automatic air pillow su …

Metzingen. The Airplus Autofeed system from Storopack provides a space-saving alternative to silos at the packing station. An Airplus GTI series unit drops air pillows produced on a sensor-controlled basis from a frame extendable to a height of 2.5 meters. The continuous supply of pillows is guided in the form of a loop to the working height of the packer, who simply tears off the required number of pillows. The…