Press release

SABIC’S DEDICATED LDPE FOAM GRADES FOR MEAF AND ASIA

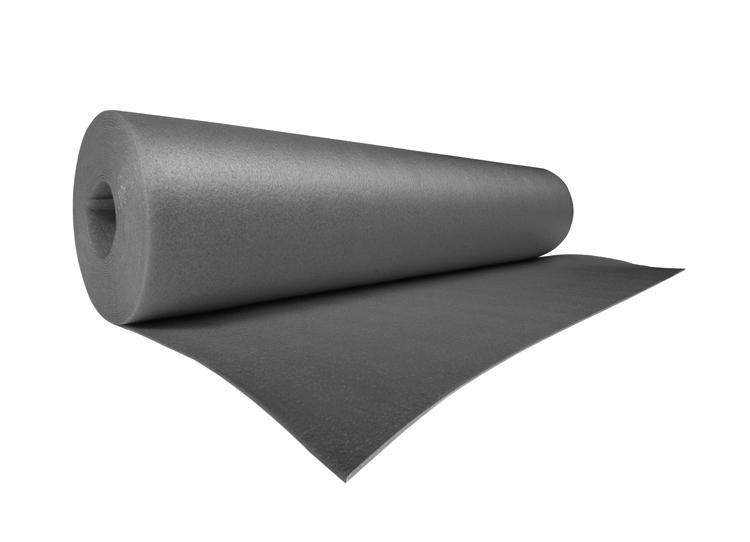

Polymeric foams are widely used in numerous areas that encompass building & construction, automotive, packaging, sports & leisure, and more. Enhanced physical properties and excellent foamability of the polymers are key in enabling more efficient material usage and energy savings.At the beginning of 2016, during the Chinaplas event, SABIC announced the launch of two new dedicated foam grades, SABIC® LDPE HP2024JDF and HP2024NDF, for Middle East, African, and Asian markets for physical extrusion foam. These grades have been successfully adopted by the market. SABIC is committed to the ongoing development of innovative solutions beyond its established foam solutions portfolio, and therefore is additionally launching a new dedicated foam grade, SABIC LDPE HP0824NDF, to broaden the application window for the tapes, seals and underlayment market. The advantages of SABIC LDPE HP0824NDF are the high viscosity, giving good head pressure for uniform and thicker foam thickness, relatively higher resin density for better mechanical strength, and good compression stress as well as resilience.

In foam processing, the product quality and consistency of foam grades, including security of supply, are key requirements for customers. SABIC’s newly developed dedicated LDPE foam grades will help customers address their specific needs.

Next to SABIC LDPE HP2024NDF and HP2024JDF, a new dedicated LDPE foam grade SABIC LDPE HP0824NDF, will be launched in the beginning of 2017. SABIC LDPE HP0824NDF offers special benefits using various foam production processes such as physical foam extrusion, the chemical cross-linking process, as well as the bun process resulting in lightweight foams. It offers material and energy savings, while retaining or even improving product performance; and it offers benefits in thermal and acoustic insulation, cushioning and protection. SABIC is helping to improve these benefits by enhancements to the physical properties and foamability of the polymers themselves.

All three grades are less sensitive to web-breaks and foam-collapse due to high consistency and a wider operating window compared to existing materials in the market, resulting in a higher material yield during processing. The foams produced give a higher compression strength, better resilience, uniform surface and cell structure, and fewer pinholes, as well as better dimensional stability compared to existing materials. This offers opportunities for material savings during production.

The new dedicated foam grades were developed in the recently opened Foam Innovation Center. Here, SABIC develops new polymer-based solutions that can help the entire value chain become more efficient, more sustainable, and more profitable. SABIC is developing more dedicated LDPE foam grades to provide a wider product portfolio for customers. The centre is equipped with most foam processing capabilities, as well as analytical equipment, enabling SABIC to carry out developments on new foam solutions, technology innovations, and collaborative projects with customers, to reduce material footprint, enable energy and cost reductions, and decrease time to market.

SABIC already has more than 35 years of experience in foams, and a significant share of the market for foamable polyolefins, with foam grades produced in Europe and in Saudi Arabia. SABIC has put in place dedicated global business, marketing and sales teams, together with technical and compliance experts, to offer insights on customized applications and solutions with the most added value. This new set-up will enable a more focused and faster implementation of solutions to meet the needs of customers and partners around the world.

To download SABIC's foam vision article, please click here (http://www.pressreleasefinder.com/prdocs/SABICPR276_Foam_Vision_article-e.pdf).

NOTES TO EDITORS

• SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates.

• SABIC is a registered trademark of SABIC Global Technologies B.V. or its affiliates

• High-resolution photos are available upon request.

• SABIC should be written in every instance in all uppercase.

ABOUT SABIC

SABIC is a global leader in diversified chemicals headquartered in Riyadh, Saudi Arabia. We manufacture on a global scale in the Americas, Europe, Middle East and Asia Pacific, making distinctly different kinds of products: Chemicals, Plastics, Agri-Nutrients, Metals, and Specialties.

We support our customers in identifying and developing opportunities in key end markets such as Construction, Medical Devices, Packaging, Agri-Nutrients, Electrical and Electronics, Transportation, and Clean Energy.

SABIC recorded a net profit of SR 18.77 billion (US$ 5 billion) in 2015. Sales revenues for 2015 totaled SR 148.09 billion (US$ 39.49 billion). Total assets stood at SR 328.22 billion (US$ 87.53 billion) at the end of 2015.

SABIC has more than 40,000 employees worldwide and operates in more than 50 countries. Fostering innovation and a spirit of ingenuity, we have filed more than 10,960 patents, and have significant research resources with innovation hubs in five key geographies – USA, Europe, Middle East, South East Asia and North East Asia.

The Saudi Arabian government owns 70 percent of SABIC shares with the remaining 30 percent publicly traded on the Saudi stock exchange.

At SABIC, we combine a rich track record of doing what others said couldn’t be done, with a deep understanding of our customers. But our true impact is as a partner who can help our customers achieve their ambitions by finding solutions to their challenges. We call this ‘Chemistry that Matters™’.

Marketing Solutions

Box 6

2950

Kapellen

Belgium

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SABIC’S DEDICATED LDPE FOAM GRADES FOR MEAF AND ASIA here

News-ID: 409115 • Views: …

More Releases from SABIC

SABIC launches new LNP™ compound offering easy plating with LDS, warpage contr …

SABIC, a global leader in the chemical industry, today introduced LNP™ THERMOCOMP™ OFC08V compound, a material well suited for 5G base station dipole antennas and other electrical/electronic applications. This new compound can help the industry develop lightweight, cost-effective, all-plastic antenna designs that facilitate deployment of 5G infrastructure. In an era of increasing urbanization and smart cities, broad availability of 5G networking is urgently needed to provide fast, reliable connectivity for…

SABIC COLLABORATES WITH KRATON FOR CERTIFIED RENEWABLE BUTADIENE TO PRODUCE CERT …

SABIC, a global leader in the chemical industry, has announced a new collaboration with Kraton, a leading global sustainable producer of specialty polymers and high-value biobased products derived from pine wood pulping co-products, to deliver certified renewable butadiene from its TRUCIRCLE™ portfolio for use in Kraton's certified renewable styrenic block copolymers (SBC). This effort forms part of SABIC's 2025 strategy, which includes a Sustainability Development Goal roadmap spanning the organization's…

SABIC’s new ISCC+ certified bio-based LNP™ ELCRIN™ copolymer resin helps t …

SABIC, a global leader in the chemical industry, has introduced LNP™ ELCRIN™ EXL7414B copolymer, the company’s first bio-based polycarbonate (PC) copolymer to help advance the consumer electronics industry’s net-zero carbon emissions goals. The new copolymer is the first grade in an expanding portfolio to secure the International Sustainability and Carbon Certification Plus (ISCC+) designation. It is formulated with over 50 percent bio-based content from waste materials, which do not compete…

SABIC opens new pp compounding line in Genk, Belgium to meet growing demand in a …

SABIC, a global leader in the chemical industry, has announced today the start-up of its new polypropylene (PP) compounding line in Genk, Belgium with a virtual inauguration event. The new line is an addition to the company’s existing production capacity for SABIC® polypropylene compounds at the Genk site and will use raw materials from SABIC’s PP plants at Gelsenkirchen, Germany, and Geleen, The Netherlands. It has been equipped with cutting-edge…

More Releases for LDPE

Polyethylene (HDPE, LDPE, LLDPE) Market 2022 | Detailed Report

The market report delivers an all-inclusive analysis of the market structure along with a forecast of the various segments and sub-segments of the Polyethylene (HDPE, LDPE, LLDPE) industry. This wide-ranging market research report acts as a backbone for the success of business in any niche. The Polyethylene (HDPE, LDPE, LLDPE) market survey report has been prepared by conducting market research in a systematic manner. Moreover, the Polyethylene (HDPE, LDPE, LLDPE)…

Low Density Polyethylene (LDPE) Foams Market Forecast 2030

Albany, NY - Low Density Polyethylene (LDPE) Foams Market: Introduction

The global low density polyethylene (LDPE) foams market was valued at ~US$ 1.5 Bn in 2019 and is anticipated to expand at a CAGR of ~5% during the forecast period. The global LDPE foams (LDPE) market is expected to expand at a rapid pace during the forecast period, due to the increase in penetration of LDPE foams in various sectors, particularly…

Low Density Polyethylene (LDPE) Foams Market Forecast 2030

Albany, NY - Low Density Polyethylene (LDPE) Foams Market: Introduction

The global low density polyethylene (LDPE) foams market was valued at ~US$ 1.5 Bn in 2019 and is anticipated to expand at a CAGR of ~5% during the forecast period. The global LDPE foams (LDPE)

market is expected to expand at a rapid pace during the forecast period, due to the increase in penetration of LDPE foams in various sectors, particularly packaging,…

Global LDPE Packaging Market 2017-2021

WiseGuyReports.Com Publish a New Market Research Report On - “Global LDPE Packaging Market 2017-2021”.

The analysts forecast the global LDPE packaging market to grow at a CAGR of 5.77% during the period 2017-2021.

LDPE packaging refers to the packaging of products using packaging materials. These packaging materials are manufactured using LDPE polymer resins. LDPE is manufactured by the polymerization of ethylene at a high temperature range in a tubular reactor. LDPE consists…

Sales of Global LDPE Geomembrane

LDPE Geomembrane Report by Material, Application, and Geography – Global Forecast to 2021 is a professional and in-depth research report on the world's major regional market conditions, focusing on the main regions (North America, Europe and Asia-Pacific) and the main countries (United States, Germany, united Kingdom, Japan, South Korea and China).

The report firstly introduced the LDPE Geomembrane basics: definitions, classifications, applications and market overview; product specifications; manufacturing processes; cost structures,…

Global LDPE Decking Market Research Report 2017

LDPE Decking Revenue, means the sales value of LDPE Decking This report studies LDPE Decking in Global market, especially in North America, Europe, China, Japan, Southeast Asia and India, focuses on top manufacturers in global market, with capacity, production, price, revenue and market share for each manufacturer, covering Azek Building Products Cardinal Building Products UPM Kymmene Universal Forest Products Advanced Environmental Recycling Technologies Fiberon Tamko Building Products Certainteed Corporation Duralife…