Press release

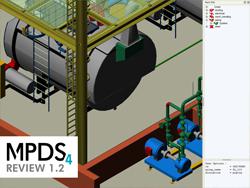

MPDS4 REVIEW 1.2 Release: 3D Review Tool for Industrial Plants and Data

The new version of CAD Schroer’s external 3D review tool for MPDS4 and MEDUSA4 data makes it even easier for industrial designers to communicate ideas and changes to project stakeholders and customersCambridge, UK and Pittsford, NY – 24October 2013: CAD Schroer has announced the release of version 1.2 of MPDS4 REVIEW. The latest version includes new structure information, measuring and 3D view options.

About MPDS4 REVIEW

MPDS4 REVIEW is an external 3D review and feedback tool. The software is used to interactively review MEDUSA4 3D CAD data in detail, or to walk through an entire industrial plant, generated by CAD Schroer’s MPDS4 plant design system. The system enables users to see model properties and attach comments for designers, which are saved with the model.

Product Web Page and Datasheet:

http://www.cad-schroer.com/products/mpds4/visualisation.html

Gaining a Structural Overview

In addition to showing details and attributes for selected components within a plant or factory, version 1.2 now allows users to gain an overview of the structure of the 3D data by providing a structure tree, which lists systems, subsystems, and individual components.

Measuring Distances

Version 1.2 now also allows users to measure distances between components, and to display these distances on the screen. The model can be saved with distances displayed.

Saving 3D Views for Collaborators and Customers

In addition to the existing tools for choosing different views and conducting camera-like 3D walk-throughs, MPDS4 REVIEW now allows users to name and store different views of a model or plant, which can then be selected and displayed at any time.

This makes the tool even more ideal for collaboration with suppliers, colleagues and customers, as different views can be saved with a model, which can quickly be selected during a presentation to (or by) a customer, or during a meeting with collaborators.

MPDS4 REVIEW version 1.2 is available for immediate download for CAD Schroer maintenance customers via its Customer Portal. For more information, please visit:

http://www.cad-schroer.com/products/mpds4/visualisation.html

About CAD Schroer

CAD Schroer is a global software development company and engineering solutions provider, helping to raise the productivity and competitiveness of customers working in manufacturing and plant design, including the automotive sector and its supply chain, the energy sector and public utilities. CAD Schroer has offices and subsidiaries throughout Europe and in the United States.

CAD Schroer’s product portfolio includes 2D/3D CAD, plant design, factory layout and data management solutions. Customers in 39 countries rely on MEDUSA4®, MPDS4™ and STHENO/PRO® to provide an efficient, flexible and integrated design environment for all phases of product or plant design – cutting costs while raising quality. CAD Schroer emphasises close customer partnerships and supports its clients’ objectives through extensive consultancy, training, development, software support and maintenance services.

CAD Schroer UK Limited

2nd Floor, Godwin House

Castle Park

Cambridge CB3 0RA

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release MPDS4 REVIEW 1.2 Release: 3D Review Tool for Industrial Plants and Data here

News-ID: 274037 • Views: …

More Releases from CAD Schroer UK Limited

Revolutionise your P&ID designs with the help of a modern software package

Cambridge, UK and Pittsford, NY – 08 March 2017: One of the first tasks when designing process plant is the creation of P&IDs. Depending on the tools used, the design time required and the quality of the results varies.

Revolutionise your P&ID designs

Unnecessary work during P&ID design

Many businesses use outdated methods to produce their P&ID flowcharts. The work is per-formed either on paper or with a rudimentary software…

Better collaboration thanks to cloud connected CAD software

Modern CAD systems offer integration with cloud services such as Dropbox and Google Drive, in addition to PDM systems.

Cambridge, UK and Pittsford, NY – 15 February 2017: Modern CAD systems offer integration with professional data-management systems, but these powerful systems are often too expensive for small businesses to implement. So there is a clear need for a simpler, more cost-effective solution.

Cloud integration with Dropbox, Google Drive and Microsoft OneDrive

Cloud data…

More Releases for MPDS4

Faster Plant Design & Factory Layout with MPDS4 6.2

MPDS4 version 6.2 offers extensive new functionality and productivity enhancements for plant design and factory layout applications.

Cambridge, UK and Pittsford, NY - 28 June 2017: MPDS4 version 6.2 includes new functionality for improved reporting and a simpler user experience. The optimisation of interfaces simplifies data exchange with customers and suppliers.

Simpler and faster design

The main focus of version 6.2 is to achieve a simpler user experience through improved functionality, and faster…

Plan systems and factories even better with MPDS4 6.2

Version 6.2 offers lots of new productivity improvements and functions to the plant construction and factory planning software MPDS4.

Cambridge, UK and Pittsford, NY - 21 June 2017: MPDS4 version 6.2 includes a large amount of new functions for improved reporting and simpler handling. The expansion and optimisation of interfaces simplifies the exchange of data with customers and suppliers.

Simpler and better planning

The main focus of version 6.2 was to achieve easier…

P&IDs, pipework and piping isometrics in one go – yes, this is possible!

MPDS4 provides an integrated suite of intelligent software that enables design information to flow from the P&ID to 3D pipework layout and onto the production of piping isometric drawings.

Cambridge, UK and Pittsford, NY – 25 January 2017: The use of MPDS4 offers huge potential for savings. Design work can be performed more quickly and effectively and expensive tasks, such as the manual drafting of piping isometrics, are completely eliminated.

Process Plant…

The Art of Integrated Plant Design

Plant design projects often suffer from data disconnect between different project phases. MPDS4 offers an integrated approach for all phases of a plant or factory project.

Cambridge, UK and Pittsford, NY – 23 June 2016: MPDS4, a database-driven plant design system supporting all the plant engineering disciplines, allows companies to plan, design, document and deliver plant or factory projects of any size, tightly integrated with other corporate data and processes.

Efficient…

MPDS4 R6: A new Chapter for Plant Design and Factory Layout Planning

CAD Schroer has once again set standards in design, ergonomics and technology with the latest generation of its plant design and factory layout software.

Cambridge, UK and Pittsford, NY – 20 April 2016: Today is the day; CAD Schroer releases the result of years of research, analysis and development with the latest generation of MPDS4 R6. The 3D design solution opens a new chapter for the integrated planning of manufacturing plants…

Fast and dynamic industrial 3D plant design with MPDS4 version 5.2

CAD Schroer introduces more intelligent routing tools and data exchange options with latest release of the catalog-driven large-scale plant and factory design suite

Cambridge, UK and Pittsford, NY – 5 September 2013: Version 5.2 of the MPDS4 2D/3D factory layout and 3D plant design software includes new P&ID functionality, dynamic routing and component moving tools, parametric component selection and placement enhancements, and a new 3D DWG plant export option.…