Press release

More efficient manufacturing of ceramic coatings: no problem thanks to PLANSEE's new cathode fixturing system

Hard and extremely durable: ceramic coatings make an ideal protective layer for tools and components. To date, ceramic and brittle materials could only be deposited by means of the reactive magnetron sputtering method, in part because of the lack of an appropriate fixing system for arc evaporation. But now PLANSEE has developed a suitable fixing system for ceramic and brittle composite materials. Using an integrated carrier plate and a cathode ring, tungsten carbide, chromium-silicon, titanium-diboride and titanium-chromium, among other materials, can now be used as arc-cathodes.When it comes to coating tools, arc evaporation is generally a more efficient method than magnetron sputtering. A threaded hole in the arc cathode usually fixes the coating material in the coating system. Ceramic and brittle composite materials are unsuitable for this type of mechanical machining, which they would not withstand intact. Therefore until recently tungsten carbide, for example, could only be applied to the various substrates by means of the magnetron sputtering method.

PLANSEE has now developed a new fixing system facilitating the use of ceramic and brittle composite materials as cathodes in arc evaporation. The system comprises an integrated carrier plate and a cathode ring. As the various cathode materials have different thermal expansion coefficients, molybdenum is also available as an alternative to copper as a material for the carrier plate. The cathode ring made from molybdenum or ceramic materials encloses the coating material and ensures that the arc remains on the cathode material during the coating process.

The new mounting system is suitable for arc cathodes made of tungsten-carbide, chromium-silicon, titanium-diboride and titanium-chromium, among other materials. It is particularly robust and can be reused multiple times in many cases.

PLANSEE is happy to advise you – for instance at the PSE conference in Garmisch.

International Conference on Plasma Surface Engineering (PSE)

10 – 14 September 2012

Garmisch-Partenkirchen, Germany

As the leading powder metallurgy manufacturer, PLANSEE supplies sputtering targets and cathodes made of a wide range of metals and composite materials such as titanium-aluminum, aluminum-chromium, chromium, titanium, zirconium, titanium-silicon, titanium-diboride and tungsten carbide. Our products are put to the test daily as hard material coatings on tools, components and decorative items.

For further information on arc cathodes, please visit www.plansee.com/hardcoatings

The Plansee Group is a leader in the field of powder metallurgy, covering the entire production process from the ore right through to customer-specific components.

The corporate division PLANSEE SE is an expert for components manufactured from molybdenum, tungsten, tantalum, niobium and chromium. Alloys and composite materials from PLANSEE come into their own in electronics, coating technology or high-temperature furnaces - wherever traditional materials are stretched beyond their limits.

Find out more about PLANSEE and locate your local contact: www.plansee.com

PLANSEE SE

Metallwerk-Plansee-Str. 71

6600 Reutte/Austria

Sandra Kieltrunk

+43 5672 600-3274

sandra.kieltrunk@plansee.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release More efficient manufacturing of ceramic coatings: no problem thanks to PLANSEE's new cathode fixturing system here

News-ID: 235049 • Views: …

More Releases from PLANSEE SE

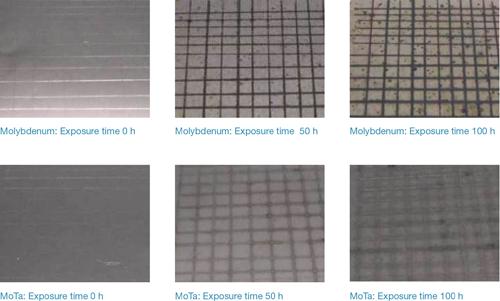

Molybdenum-tantalum: The corrosion-resistant material for CIGS solar cells.

Thanks to its good adhesion to glass and a high electrical conductivity, molybdenum is the back contact material in CIGS solar cells. However, exposed to corrosive atmospheres molybdenum can be prone to oxidation. In order to avoid negative effects during the manufacturing process and the solar module operation, PLANSEE has developed a material with improved corrosion resistance.

The company alloys pure molybdenum with small amounts of corrosion-resistant tantalum, and thereby combines…

The influence of sputtering targets on the manufacturing costs and efficiency of …

The sputtering process is the most important technique for material deposition in CIGS-manufacturing. With innovative sputtering targets CIGS producers can significantly reduce their production costs.

Manufacturers of sputtering targets like PLANSEE have two approaches to reduce CIGS module manufacturing costs: In order to lower the material consumption by a better target utilization PLANSEE introduced the new monolithic and dogbone rotary target designs. With MoNa the company offers a new material alloy…

PLANSEE Tantal Certified by EICC as „Conflict-Free“

Sustainability is an integral part of PLANSEE purchasing policy. The socially and environmentally responsible procurement of raw materials is set in the Code of Conduct. Strict purchasing guidelines ensure that no materials are obtained from conflict-affected areas.

The use of tantalum raw materials from ethically acceptable sources has now been confirmed by the certificate of the Electronic Industry Citizenship Coalition (EICC). The decree covers all steps of material production.

The audit as…

Thorium-free TIG welding electrodes gain in popularity

Not only health considerations, but also additional costs for the packaging of radioactive thorium-containing welding electrodes lead more and more PLANSEE customers to switch to thorium-free alternatives.

Tungsten electrodes contain different doping agents such as thorium oxide, lanthanum oxide or cerium oxide. These increase the heat resistance of the electrode and reduce the electron work function. Thus, the electrons release themselves from the tungsten electrode’s atomic orbit using less energy and…

More Releases for PSE

Bowhuntings market: Market Indicators Showing Positive Outlook | Dead Ringer, PS …

"

The Bowhuntings global market is thoroughly researched in this report, noting important aspects like market competition, global and regional growth, market segmentation and market structure. The report author analysts have estimated the size of the global market in terms of value and volume using the latest research tools and techniques. The report also includes estimates for market share, revenue, production, consumption, gross profit margin, CAGR, and other key factors. Readers…

Portable Solar Reflectometers Market Witness High Growth And Manufacturing Analy …

QY Research has recently published a new report, titled Global Portable Solar Reflectometers Market Report, History and Forecast 2017-2028, Breakdown Data by Manufacturers, Key Regions, Types and Application. The report has been put together using primary and secondary research methodologies, which offer an accurate and precise understanding of the Portable Solar Reflectometers market. Analysts have used a top-down and bottom-up approach to evaluate the segments and provide a fair assessment…

Crossbows Industry Top Key Companies Are Bowtech, TenPoint Crossbow Technologies …

This study researches the market size of Crossbows, presents the global Crossbows sales and revenue by companies, regions, type and application, history breakdown data from 2013 to 2018, and forecast to 2025. This report focuses on the key data information of Crossbows in key regions like North America, Europe, Asia Pacific, Central & South America, and Middle East & Africa, presents sales, revenue, market share, growth rate of Crossbows for…

Crossbows Global Market 2017: Key Players – Bowtech, TenPoint, Barnett Crossbo …

Crossbows Industry

Description

Wiseguyreports.Com Adds “Crossbows -Market Demand, Growth, Opportunities and Analysis of Top Key Player Forecast To 2022” To Its Research Database

This report studies the crossbows market status and outlook of global and major regions, from angles of players, regions, product types and end industries; this report analyzes the top players in global and major regions, and splits the Crossbows market by product type and applications/end industries.

In terms of revenue, the…

Global Crossbows Market 2017- PSE Archery, Barnett Crossbows, Crosman

Global Crossbows Market 2017

The Industry Study on Global Crossbows Market 2017 incorporates the entire aspects of the Crossbows market. This includes extensive analysis, recent industry statistics and upcoming flow of the Crossbows market. The report also describes the size of the Crossbows market, factors controlling Crossbows market growth, various challenges which affect market expansion and economic prominence of the Crossbows market globally.

Global Crossbows Market report commences with the overview of…

Global Crossbows Market 2017 - Bowtech, Barnett Crossbows, Crosman, PSE Archery, …

The report published on the Crossbows market provides an analytical view of the Crossbows industry’s performance in the global scenario. In a detailed chapter-wise format, the study evaluates the numerous aspects corresponding to the global Crossbows market. To begin with, the market definition, applications, classification, and industry value chain structure is included in the report, to update stakeholders on incumbent market dynamics. Development trends exhibited by the Crossbows market globally…