Press release

iWave Systems launch high-performance HMI platforms using FPGA architecture

The HMI technology has revolutionised the industrial world, offering a completely new perspective on how we interact with machines and optimize their performance. From ATMs, vending machines, ticketing systems to home automation and smart factories, HMIs have become ubiquitous and an integral part of everything “SMART”. Recent developments in technology, IoT and edge computing have contributed to further sophistication of existing HMI technology, leading to much more intelligent and interactive interface.In industrial settings, HMIs can be used to:

• Monitor machine inputs and outputs

• Quickly locate malfunctions and enable faster troubleshooting

• Track various problems and optimize manufacturing process to increase productivity

• Provide a realistic view of plant operations

• Remotely control the facility from a central location

• Easily test devices and equipment with simulations

• Reduce operation costs and simplify maintenance

• Improves communications among various types of equipment

• And more

Key challenges of the existing HMI technology:

Industrial HMI applications demands interface solutions that are extremely accurate and reliable. The algorithms that drive these applications may require continuous upgrades and design changes to meet the evolving market demands. An ASIC based HMI solution cannot scale up to these escalating performance requirements as they cannot be re-programmed.

Some of the key limitations of ASIC processor based HMI include:

• Inability to meet changing I/O and multimedia demands

• Failure to incorporate new and multiple value-added services

• High latency and response time due to increased processing time

• High power consumption and heat dissipation

• Limitations in peripheral interfaces

• No fail safe feature in communication standards

• Inability to manage concurrent applications efficiently

• Multiple processors to perform various applications takes up space and increase cost

• Complex physical design

How FPGA can overcome these limitations:

Adopting a reprogrammable FPGA architecture such as the Xilinx Zynq 7000 SoC can dramatically improve system performance and efficiency. The Xilinx Zynq 7000 SoC FPGA is a single device that can have different blocks to do different operations. This allows designers to utilize one piece of hardware flexibly, for multiple purposes. Since it can be reprogrammed, new features can constantly be added and fine-tuned to meet evolving design requirements.

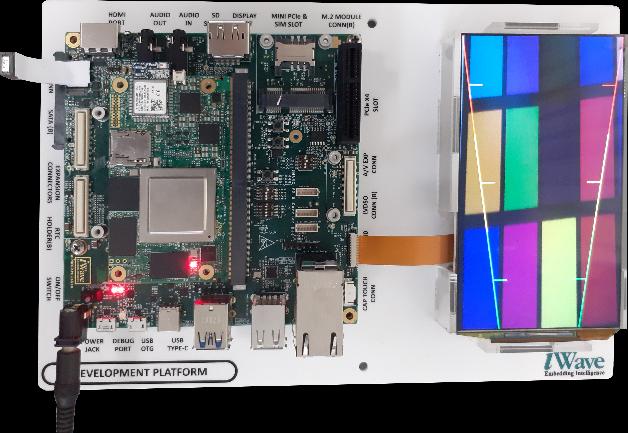

iWave Systems is now offering advanced HMI platforms based on Xilinx Zynq-7000 System on Modules. The high performing HMI platforms integrates Dual Cortex A9 CPU @ 866MHz, combines 85K FPGA logic cells and up to 120 FPGA IOs. The HMI is equipped with on-board QSPI flash, eMMC, DDR3 RAM, Wi-Fi, BT, Gigabit Ethernet, MIPI Camera, HDMI and a host of other interfaces for peripheral functions.

The Xilinx 7000 SoC based HMI solution offers a long list of benefits:

• Surpassing execution speed due to inherent parallelism

• Programmable Logic utilized for realizing specific repeated tasks related to Industrial Ethernet, camera interface, image, serial ports, digital signal processing etc.

• FPGA responsible for display control and 3D graphics rendering

• Support an extensive range of standard peripherals, serial ports and Industrial Ethernet standards

• Offer ample flexible I/O with the capability to build interfaces for any sort of non-standard or proprietary requirements

• HSR/PRP Protocol IP implementation in FPGA provides network redundancy, guaranteeing high availability and ensuring no frame loss in the presence of an error

• Reduced system BOM cost and form factor

• Enables Asymmetric Multiprocessing (AMP) through Dual Boot Implementation (Bare-Metal, Linux) on Programming System

• Custom BSP/SDK and API/test application

• Standard/ Non-standard wired & wireless connectivity protocol/stack development/porting

• Industrial Grade Linux

• Rapid development of GUI

• Software/Hardware/Enclosure customization support

• Industrial connectivity: RS485, EtherCAT, RS232, USB, CANopen, Ethernet

• Proprietary camera interface support

• Support framework for embedded analytics and machine learning

iWave’s Xilinx Zynq 7000 SoC based HMI platforms offers flexible interfaces and advanced HMI functions, while reducing power consumption and cost. The versatile FPGA platform can support maximum reuse and best time to market, enabling developers to build a highly reliable system that meets evolving industry demands.

For further information https://www.iwavesystems.com/product/solutions/hmi-odm-solution/human-machine-interface.html or for any enquiries please write to mktg@iwavesystems.com or contact our Regional Partners.

iWave Systems Technologies Pvt. Ltd.

No. 7/B, 29th Main, BTM Layout 2nd Stage,

Bangalore - 560 076, India

Phone: +91-80-26683700, 26781643, 26786245

Fax : +91-80-26685200

iWave Systems Technologies, an ISO 9001:2015 certified company, established in the year 1999, focuses on standard and customised System on Module/SBC product development in Industrial, Medical, Automotive & Embedded Computing application domains. iWave Systems also provides comprehensive Engineering design services involving Embedded Hardware, FPGA and Software development.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release iWave Systems launch high-performance HMI platforms using FPGA architecture here

News-ID: 1782462 • Views: …

More Releases from iWave Systems

The Cortex® M4F: Enabling next-generation real-time processing in i.MX8QM SMARC …

iWave systems recently launched a new SMARC System on Module (SOM) based on the powerful NXP® i.MX 8QuadMax applications processors. This high performance SOM features an intelligent blend of MPUs+MCU power in a single device and integrates heterogeneous multicore 64 bit ARM® processors (Dual Cortex® A72@ 1.8 GHz + Quad Cortex® A53 @ 1.2 GHz and Dual Cortex® -M4F @ 266 MHz), targeted for applications that demand advanced real-time processing,…

XEN virtualization on iWave’s i.MX8QM System on Module

iWave Systems, a leading embedded solutions provider company based in Bangalore has successfully demonstrated Xen virtualization hypervisor on their i.MX8 QM SoC based System on Module. The multi-core SOM comprises of 2x Arm® Cortex®-A72 @1.8 GHz and 4x Arm® Cortex®-A53 @1.2 GHz and 2x additional Cortex®-M4F @ 266 MHz, rendering a highly powerful integrated solution on a SMARC R2.0 compatible module.

To fully explore the enormous computing capability of the i.MX8…

iWave OBD II Secured Edge Analytics Solution

Transform your ordinary vehicle into a smart vehicle

Presenting iWave’s revolutionary Plug and Play OBD II vehicle tracking and diagnostics solution. The device offers an innovative way to track and interact with your vehicle anytime anywhere. The high-spec OBD II scanner offer high accuracy location tracking, turn by turn navigation combined with real-time vehicle diagnostics, enhanced security features and much more …all in a single compact device.

…

More Releases for HMI

Increasing Clamor Around RSE Display HMI System Likely to Fuel Steering Mounted …

The automotive industry is one of the fastest-growing industries, significantly contributing to the gross domestic product of several countries. Unfortunately, the COVID-19 pandemic posed serious challenges for which the industry was under-prepared. Halted production and disruptions in the supply chain resulted in a huge setback in the automotive industry.

However, with the acceleration in the vaccination process across several countries like the U.K., the U.S., Germany, India, and China, manufacturers are…

Human Machine Interface Market (HMI) by Advanced PC-Based HMI, Advanced Panel-Ba …

Human-machine interface (HMI), also commonly known as man-machine interface (MMI), is an interface between the user and the machine which helps operators and line supervisors to coordinate and control the manufacturing process in the plant. The interface comprises hardware and software that help operators convert complex process variables into actionable and usable information. It minimizes human involvement in the manufacturing process, thereby increasing the process productivity and safety of the…

Automotive HMI Market Growing at 12.31 CAGR by 2025 |Type (Visual Interface, Aco …

Automotive HMI Market 2019 Industry report provides an analytical assessment of the prime challenges faced by this market currently and in the coming years, which helps industry participants in understanding the problems they may face while operating in this industry over a longer period of time. This report is insights of the data that translate into a gist of this industry.

You can get a sample copy of this report at…

Human Machine Interface Market Report 2018: Segmentation by Offering (Hardware ( …

Global Human Machine Interface market research report provides company profile for ABB Ltd. (Switzerland), Advantech Co., Ltd. (Taiwan), Emersion Electric Co. (U.S.), General Electric Co. (U.S.), Honeywell International Inc. (U.S.), Kontron AG (Germany), Mitsubishi Electric Corporation (Japan), Rockwell Automation, Inc. (U.S.) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in…

Global HMI Software Development Market 2017-2021

"Global HMI Software Market 2017-2021" The Report covers current Industries Trends, Worldwide Analysis, Global Forecast, Review, Share, Size, Growth, Effect.

Description-

About HMI Software

HMI software is used to control the operation of a plant and this helps in improving the efficiency of the factory. This software aids in providing real-time data and data logging that are used in analytics to make strategic decisions.

Technavios analysts forecast the global HMI software market to grow…

HMI 2010: Kithara presents new Profibus Master

Real-Time extension now supports the Profibus cards of Hilscher

The Windows real-time environment »RealTime Suite« of the Berlin company Kithara Software now supports time-critical applications with Profibus, too. Therewith this proved and widely-used fieldbus system can be used in future with Windows in real time.

Despite of the undeniable trend to Ethernet-based automation protocols, Profibus is currently the system with the most widely-use and furthermore high growth. However, with Windows it was…