Press release

Rolling bearing analysis for track rollers

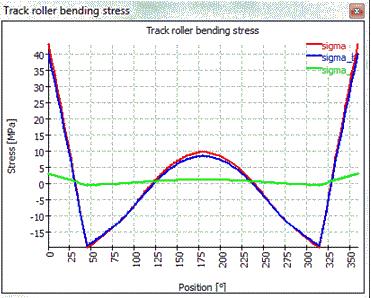

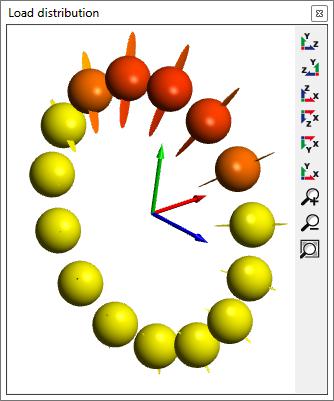

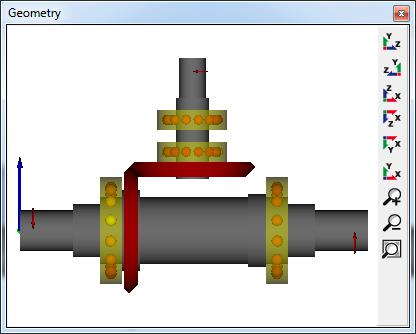

The rolling bearing analysis according ISO/TS 16281 is assuming rigid races. This is an appropriate approximation if the bearings is mounted on a shaft and surrounded by a stiff housing. In case of a track roller the external load is acting directly on the outer ring which is therefore deformed.The elastic deformation affects the load distribution in the rolling bearing, which leads to a different hertzian stress and life. In bearing catalogues for track rollers often reduced effective load capacities are provided for this reason. In addition to hertzian stress or life also the bending stress in the outer ring can be critical in track rollers.

Supports for planetary gears with a thin rim are loaded similar to track rollers. There are two loadings deforming the gear body and therefore the load distribution in the rolling bearing.

An extension to MESYS rolling bearing calculation according ISO/TS 16281 for track rollers is now available. The outer ring geometry and the loading on one or more locations can be provided by the user. Deformations and stresses in the outer ring are calculated and shown graphically. The load distribution and the life of the bearing are then calculated with this deformations. Optionally the reduced effective load capacities and the permissible radial load for the outer ring can be calculated.

Further details are available on www.mesys.ch.

MESYS AG in Zurich (Switzerland) is developping software for technical calculations in mechanical engineering. The main focus is the sizing of machine elements as gears or rolling bearings. In addition to standardized software also custom software is developped.

We also support you in design of machine elements especially for gears or we can do ratings according different standards.

MESYS AG

Binzstrasse 18

CH-8045 Zürich

www.mesys.ch

T: +41 44 4556800

Contact: Markus.Raabe@mesys.ch

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Rolling bearing analysis for track rollers here

News-ID: 160949 • Views: …

More Releases from MESYS AG

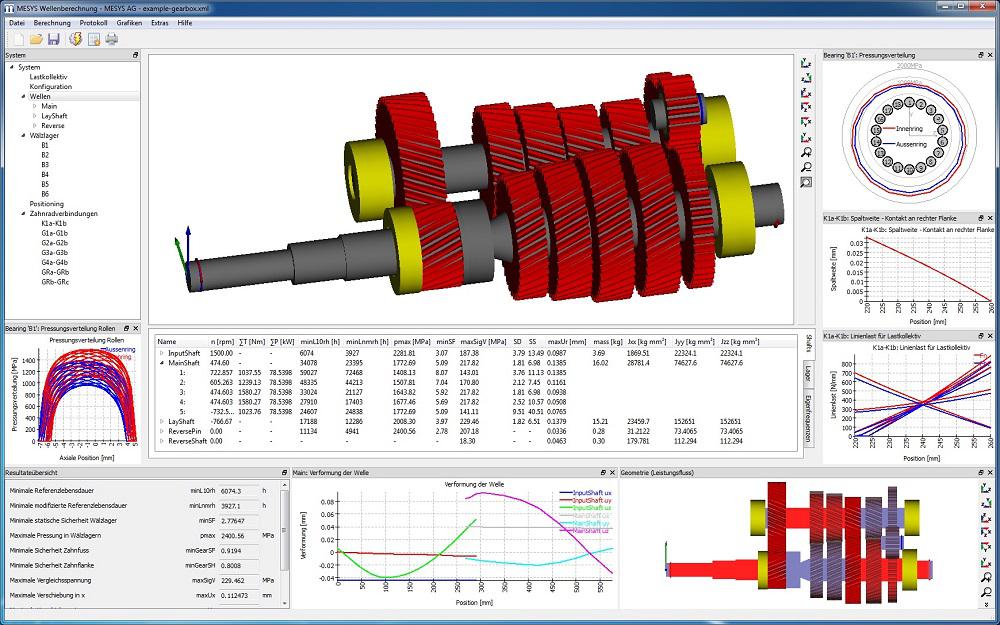

MESYS published a new version of its shaft and bearing calculation software

The MESYS Rolling bearing calculation allows the calculation of bearing load distribution and bearing life according ISO/TS 16281. It is available as standalone application or integrated in a shaft system calculation with additional possibilities like modal analysis, shaft strength calculation according DIN 743 or coupling to gear calculation programs.

New features have been added for the release 08/2014. Spanish language is now selectable for both software and report. Furthermore, an editable…

Version 12/2013 of MESYS Shaft and Rolling Bearing calculation is available

MESYS Rolling Bearing Calculation is used to calculate load distribution and life according ISO/TS 16281 for rolling bearings. The new version adds the following features:

- Cross roller bearings as new bearing type

- Custom extensions for database tables for bearing clearance and tolerance

- A modified logarithmic profile can be used for roller bearings

- A load rating diagram shows permissible moment load over axial load for different criteria

- A diagram for ball…

New version of MESYS Shaft and Rolling Bearing Calculation is available

A new version of MESYS Shaft and Rolling Bearing Calculation is available now.

The bearing calculation now supports an extended method for pressure distribution for all types of roller bearings. This allows the evaluation of different profiles for rollers and races.

Serveral possibilities are added to support material influence on load capacities. Permissible stresses for calculation of static capacity or fatigue limit can now be specified for material selections.

The shaft calculation…

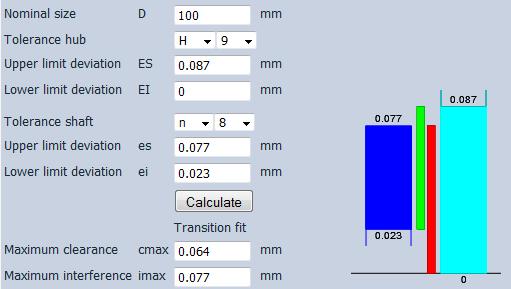

Free online calculation for fits according ISO 286

The free online calculation for fits according ISO 286 (2010) on the website of MESYS AG was updated.

Now the clearance or interference resulting from a fit like H7/n6 is not only shown in numbers but also graphically. So you will realize the position of tolerances at a glance without interpreting numbers. The maximum and minimum clearance or interference are also shown in the graphics. Clerance is shown in green, interference…

More Releases for Bending

Global Mobile Bending Machine Market Research

Global Mobile Bending Machine Market Research Market Study Mobile Bending Machine Market Provide Forecast Report 2018 – 2025 presents a point by point examination of the Mobile Bending Machine which explored industry circumstances, advertise Size, development and requests, Mobile Bending Machine showcase viewpoint, business procedures used, focused investigation by Mobile Bending Machine Market Players, Deployment Models, Opportunities, Future Roadmap, Value Chain, Major Player Profiles. The report likewise introduces figures for…

Optimized bending production - New software facilitates daily work

Just in time for the EuroBLECH, AICON 3D Systems launches version 3.1 of the software platform BendingStudio. Especially user-friendliness was revised.

Interconnected work at different workstations becomes even more efficient. The module DATA SERVICE is more transparent: Connections to other workstations are visibly displayed. The user sees network problems immediately and can directly restore the network connection. Furthermore, currently used components are marked in the selection lists. They are displayed in…

Efficient tube bending machines for every application

Hannover Messe (Germany): Tube bending at the highest level for the best results with the t bend tube bending machines from transfluid

For specific challenges only tailored solutions bring the best results, especially when intelligent and economic technology for tube processing is in demand.

The specialists for tube processing machines and tube bending machines offers versatile options to customize the machines for the special requirements of industrial applications.

For optimal manufacturing processes transfluid…

Pipe bending: Cost-efficient bending of hose fittings

Tube bending maschines: transfluid offers two fast processing systems for different sizes

Special solutions are required for special requirements – or just one efficient, customisable solution. For one-part hose fittings the german transfluid Maschinenbau GmbH has developed such a "twin" pipe bending solution and will equip its tube bending maschines systems with different modules depending on the application, varying mostly in the loading system. The challenges: Fittings are mostly mechanically processed,…

Economical bending and cutting of compact geometries

New transfluid solution provides more time and material efficiency

In short and compact tube geometries, the problem is that with standard methods the material loss is extremely high, if must be cutted after bending the tubes. "Not acceptable", determine the developers of the transfluid Maschinenbau GmbH, Schmallenberg. With a special combination of bending and cutting process, which was developed according to the individual customer's request, provides the german company now an…

transfluid develops efficient tube bending process for smallest bending radii

pipe bending machine: Intelligent solution for single bends with tool-related bending angles between 10° and 180°

A small bending radius is easier to produce than a big one. A world turned upside down? The supplier of solutions transfluid exceeds the possibilities of conventional processes in the development of a new tube bending technology. Usually, bending radii can rarely be assembled smaller than 1 x D with higher tube diameters. transfluid has…