Press release

Modular PXI Solution for CAN Communication

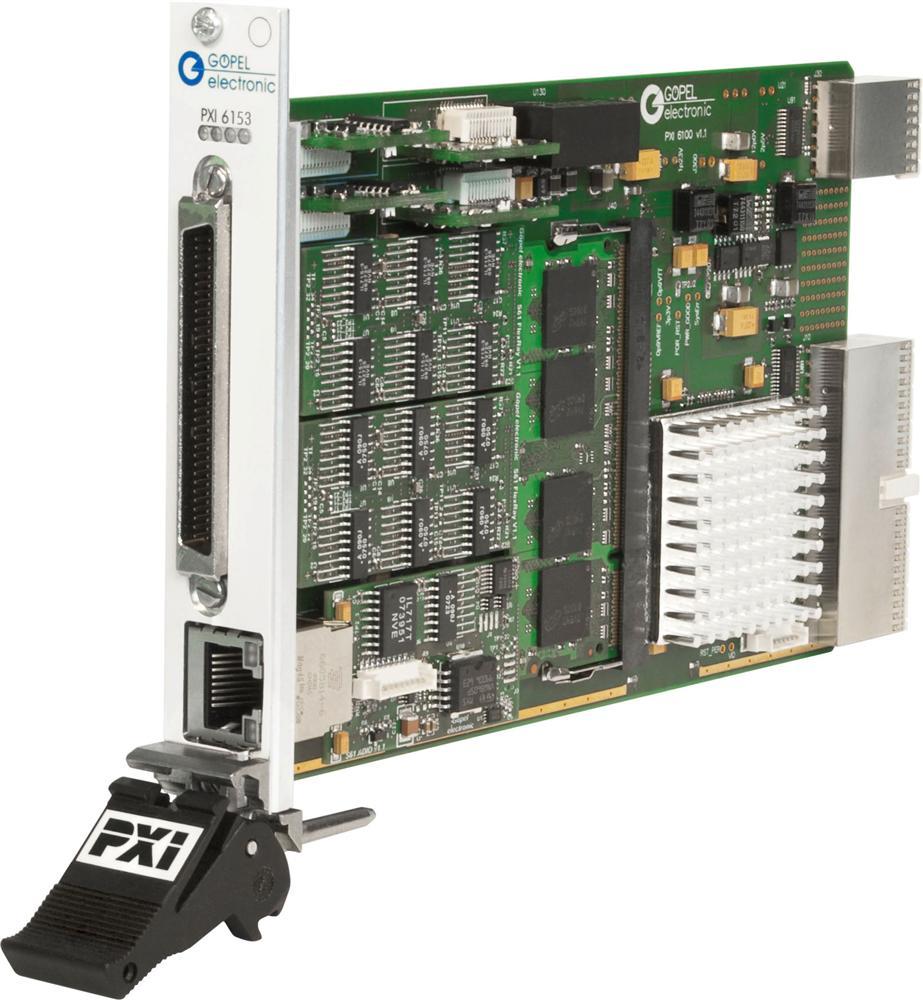

GOEPEL electronic recently introduced PXI 6153, a modular communication controller for CAN, based on the powerful well established Series 61. The scalable architecture provides an extensive range of options for individual and flexible controller configurations and functional upgradability at a later date.The basic configuration features two separate CAN communication interfaces. Optionally, they can be extended with up to four additional ports (CAN, LIN/K-line, FlexRay). The result is a multitude of configuration and application opportunities, from testing routing functions at Gateway ECUs too parallel testing several ECUs in Run-In and Screening Test systems. The module is hence able to replace several conventional interface devices during the configuration of complex test systems. In addition to reduced purchase costs for test system configurations, fewer slots in a PXI rack than normal are required, allowing for future expansion.

Comprehensive library functions of the onboard software simplify the user program generation, such as generation of transport protocols, diagnostic accesses or the implementation of network management functions. A revolutionary innovation is the opportunity to swap time critical and CPU-intensive processes of the application software to the onboard processor. Hence, the host PC is relieved and valuable bandwidth for additional application is obtained.

About GOEPEL electronic:

GOEPEL electronic is a worldwide leading vendor of professional JTAG/Boundary Scan solutions and technology innovator of IP based instrumentation. With more than 100 product launches the company became the biggest innovator in the market within the last five years. A network of branch offices, distributors and service partners ensures the global availability of the products as well as the support of the more than 7,000 system installations. Founded 1991 and headquartered in Jena, Germany, GOEPEL electronic employs currently about 170 employees and generated a revenue of 21 Million Euro in 2010. GOEPEL electronic has continuously been ISO9001 certified since 1996 and has been honoured with TOP-JOB and TOP-100 awards for being one of the best medium-sized companies in Germany. GOEPEL electronic’s products won several awards in recent years and are used by the leading companies in telecommunication, automotive, space and avionics, industrial controls, medical technology, and other industries.

GOEPEL electronics Ltd.

Unit 1A

The Old Granary

Westwick, Cambridge

CB24 3AR/UK

Phone +44-1223-858298

Fax +44-1223-257800

www.goepel.co.uk

Stefan Meissner

press@goepel.com

www.goepel.com

www.goepel.com/twitter

www.goepel.com/youtube

www.goepel.com/linkedin

www.goepel.com/xing

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Modular PXI Solution for CAN Communication here

News-ID: 160022 • Views: …

More Releases from GOEPEL electronics Ltd.

G-TAP – versatile Contacting Solution for Assembly Test

GOEPEL electronic introduces G-TAP, a worldwide unique solution for the versatile contacting of electronic assemblies - in particular the JTAG bus - for testing and programming. The G-TAP is not a single product but an overall concept, because the module can be utilized in stand-alone operations as well as an integrated solution in existing electronic and optical test systems such as Flying Probers, In-Circuit Test or AOI systems.

http://www.goepel.com/en/news/newsdetails/article/2012/11/15/g-tap-versatile-contacting-solution-for-assembly-test-from-goepel-electronic.html

“In the development…

GOEPEL electronic demonstrates first ChipVORX Prototype Instruments for Bit Erro …

At the International Test Conference (ITC) GOEPEL electronic introduces the first ChipVORX® model prototype to execute Bit Error Rate Tests (BERT) using on-board Field Programmable Gate Arrays (FPGA).

http://www.goepel.com/en/news/newsdetails/article/2012/11/08/goepel-electronic-demonstrates-first-chipvorx-prototype-instruments-for-bit-error-rate-tests.html

The new solution enables the utilisation of FPGA Embedded Instruments in the form of special softcores for the test and design validation of high-speed I/O. This will allow users to evaluate the quality of interconnections by way of bit error rates and also…

New Inline Programming System combined with Embedded Test

GOEPEL electronic announced the market introduction of additional RAPIDO™ series inline production systems for high-speed programming as well as board test based on the newest Embedded System Access (ESA) technologies.

http://www.goepel.com/en/news/newsdetails/article/2012/11/13/new-inline-programming-system-combined-with-embedded-test.html

The new models named RPS3000-(x) support double-sided probing for up to 3000 nails. Non-volatile memories such as Flash, Microcontrollers (MCU) and Programmable Logic Devices (PLD) can be on-board programmed even faster and more reliably.

Based on an enhanced SCANFLEX® architecture with…

Parallel Inline AOI for THT Components and THT Solder Joints in one System

GOEPEL electronic presents the world debut for the automatic inspection of THT assemblies: the multi awarded OptiCon THT-Line AOI system now provides a parallel inspection of THT components and THT solder joints. In a typical THT production line, now it is possible to inspect mounted components before the soldering processes as well as PCB solder joints during the return transport.

http://www.goepel.com/en/news/newsdetails/article/2012/11/13/parallel-inline-aoi-for-tht-components-and-tht-solder-joints-in-one-system.html

This gain in effectiveness for users is enabled by the OptiCon…

More Releases for PXI

PXI Market Demand and Technology Research 2025

This report focuses on the global PXI status, future forecast, growth opportunity, key market and key players. The study objectives are to present the PXI development in United States, Europe and China.

PCI eXtensions for Instrumentation (PXI) is one of several modular electronic instrumentation platforms in current use.

Get PDF Report Template @ https://www.qyresearch.com/sample-form/form/725837/global-pxi-market

PXI is designed for measurement and automation applications that require high-performance and a rugged industrial form-factor.

In 2017, the global…

PXI Market : Competitive Insight and Key Drivers 2020

Peripheral component interconnect (PCI) extensions for Instrumentation (PXI) is an open modular standard in the automated test and measurement. It offers high measurement speed, small footprint, and low power consumption compare to traditional test and measurement technique such as rack-and-stack test systems. The various application market of PXI technology include, wireless technology, aerospace, defense and consumer electronics industries.

On the basis of the various end user applications, the global PXI market…

PXI Market to Develop Rapidly by 2020

Peripheral component interconnect (PCI) extensions for Instrumentation (PXI) is an open modular standard in the automated test and measurement. It offers high measurement speed, small footprint, and low power consumption compare to traditional test and measurement technique such as rack-and-stack test systems. The various application market of PXI technology include, wireless technology, aerospace, defense and consumer electronics industries.

To View Complete Report @ : http://www.persistencemarketresearch.com/market-research/pxi-market.asp

On the basis of the various end…

PXI Market Global Forecast over BY 2021

Peripheral component interconnect (PCI) extensions for Instrumentation (PXI) is an open modular standard in the automated test and measurement. It offers high measurement speed, small footprint, and low power consumption compare to traditional test and measurement technique such as rack-and-stack test systems. The various application market of PXI technology include, wireless technology, aerospace, defense and consumer electronics industries.

A sample of this report is available upon request @ …

PXI Market to Record Sturdy Growth by 2020

Peripheral component interconnect (PCI) extensions for Instrumentation (PXI) is an open modular standard in the automated test and measurement. It offers high measurement speed, small footprint, and low power consumption compare to traditional test and measurement technique such as rack-and-stack test systems. The various application market of PXI technology include, wireless technology, aerospace, defense and consumer electronics industries.

A sample of this report is available upon request @ http://www.persistencemarketresearch.com/samples/3431

On the basis…

PXI Market Expecting Worldwide Growth by 2020

Peripheral component interconnect (PCI) extensions for Instrumentation (PXI) is an open modular standard in the automated test and measurement. It offers high measurement speed, small footprint, and low power consumption compare to traditional test and measurement technique such as rack-and-stack test systems. The various application market of PXI technology include, wireless technology, aerospace, defense and consumer electronics industries.

A sample of this report is available upon request @ http://www.persistencemarketresearch.com/samples/3431

On the basis…